Showing 61–80 of 140

-

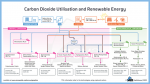

Carbon Dioxide Utilisation and Renewable Energy − Graphic (PNG)

Markets & Economy, Technology

1 Page

1537 Downloads

1537 Downloads

2023-04

FREE

1537

Downloads -

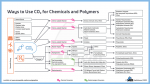

Ways to Use CO₂ for Chemicals and Polymers – Graphic (PNG)

Markets & Economy, Technology

1 Page

1110 Downloads

1110 Downloads

2023-04

FREE

Plus 19% MwSt.1110

Downloads -

Cellulose Fibres Conference 2023 (Proceedings, PDF)

Markets & Economy, Policy, Sustainability & Health, Technology

2023-03

50 € ex. tax

Plus 19% MwSt.Press

release Add to

cartThe unique conference focused on cellulose fibres – in textiles, hygiene products and packaging!

The Cellulose Fibres 2023 Conference Proceedings (https://cellulose-fibres.eu, 8-9 March 2023, Cologne, hybrid) include all released conference presentations, the conference journal, sponsor documents, a Fiber2Fashion Knowledgepaper and the conference press release.

-

nova-Session: “Bio- and CO₂-based Polymers: Production, Trends 2022-2027 and the latest Policy Developments” (Proceedings, PDF)

Markets & Economy, Policy, Sustainability & Health, Technology

2023-03

50 € ex. tax

Plus 19% MwSt.Add to

cartThe download of the proceedings contains all six presentations of the nova-Session (March 2023).

Bio-based and CO2-based Solutions – Where are we heading?

The only way for chemicals and plastics to become sustainable, climate-friendly and part of the circular economy is the complete substitution of fossil carbon with renewable carbon from alternative sources: biomass, CO2 and recycling. We see strong investment in all three sectors, with growth rates far exceeding that of fossil polymers – i.e. fossil polymers are being substituted in the market.

The session will focus on developments in bio- and CO2-based polymers and building blocks: Bio-based polymers are estimated to grow at a CAGR of 14 % from 2022 to 2027. Some examples: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

Additionally, the use of CO2 as chemical feedstock for building blocks and polymers has been intensively diversified. Several successfully implemented technologies used at commercial level are in place and many more at the laboratory and pilot phase. Besides the long-established use of CO2 for the synthesis of polycarbonates, also polyurethanes are based on it. The most notable biotechnological conversion pathway of a syngas produces ethanol at commercial scale. Additionally, high interest is also observed in CO2-based methanol and in CO2-based hydrocarbons, which can be used for fuel, chemical and polymers applications. A current total production capacity of these CO2-based products of ca. 1.3 Mt/a in 2022 is observed and a strong increase in capacity is expected by 2027.

The EU policy landscape has seen significant updates in the final weeks of 2022 with the proposed Packaging and Packaging Waste Regulation and the publication of the Policy Framework on bio-based, biodegradable and compostable plastics. How these updates may affect CO2 and bio-based polymers will be addressed in the session.

-

Advanced Recycling Conference 2022 (Proceedings)

Markets & Economy, Policy, Sustainability & Health, Technology

131 Downloads

131 Downloads

2022-11

FREE

Plus 19% MwSt.131

DownloadsThe proceedings of the Advanced Recycling Conference 2022 (14-15 November 2022, hybrid, https://advanced-recycling.eu) contain conference presentations, the conference journal, sponsor documents and the press release.

-

296 Downloads

2022-08

FREE

Free Shipping296

DownloadsAvantium has developed a technology to convert plant-based sugars into FDCA (furandicarboxylic acid), the building block of PEF (polyethylene furanoate): a plant-based, fully recyclable polymer with superior performance. FDCA is polymerised with plant-based mono-ethylene glycol (MEG) to make a 100% plant-based PEF polymer. In December 2021, Avantium has taken a positive investment decision concerning the construction of the world’s first FDCA Flagship Plant in Delfzijl (The Netherlands), with construction planned to be completed by the end of 2023 and the aim to be operational in 2024. This will be the world’s first commercial FDCA facility and will have a targeted production capacity of 5,000 tonnes per annum. FDCA is the key building block for the 100% plant-based, recyclable polymer PEF.

-

156 Downloads

2022-08

FREE

Free Shipping156

DownloadsPEF has enhanced barrier, mechanical and thermal properties compared to today’s widely used

petroleum-based polymers. The barrier properties of PEF, which are ~10x better for O2, ~15x better

for CO2 and ~2.5x better for water than PET, represent a revolutionary opportunity compared with traditional packaging solutions regarding performance, price, and sustainability when produced at scale. The improved barrier properties lead to a longer shelf life of packaged products. PEF also offers higher mechanical strength, which means that thinner PEF packaging can be produced and fewer resources are required.

In terms of thermal properties, PEF has superior ability to withstand heat and can be processed at lower temperatures. PEF has enhanced mechanical stiffness and allows for increasing shaping possibilities. -

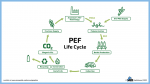

Life cycle stages of monolayer PEF bottles (PNG)

Sustainability & Health, Technology

1 Page

134 Downloads

134 Downloads

2022-08

FREE

Free Shipping134

DownloadsThis figure shows the relevant life cycle stages of monolayer PEF bottles from cradle-to-grave: from the biomass cultivation (wheat for fructose and sugarcane for bio-MEG feedstocks supply) to the production of PEF-based bottles including their end-of-life options (recycling and incineration).

It is foreseen that the commercialisation of PEF-based products will initially take place in the Netherlands, Belgium, and Germany. In these countries, the rates for average PET bottle waste collection and recycling are relatively high and landfilling is no longer practiced in these countries. -

PEF – A Sustainable Packaging Material for Bottles (PDF)

Sustainability & Health, Technology

14 Pages

801 Downloads

801 Downloads

2022-08

FREE

Free Shipping801

DownloadsThe chemical technology company Avantium (NL) partnered with nova-Institut GmbH under the framework of the PEFerence project, to perform a full cradle-to-grave Life Cycle Assessment (LCA) for the YXY® Technology, assessing the potential environmental impacts of PEF packaging solutions in comparison to conventional PET packaging. The LCA is performed according to the ISO 14040/44 standard methodology. A critical peer review of the study, including experts of incumbent technologies, was conducted in order to verify whether the LCA met the requirements for methodology, data, interpretation, and reporting. This brochure summarizes the main aspects about the environmental sustainability of PEF-based bottles.

-

Environmental impacts of 250 ml monolayer and PET/PEF multilayer bottles vs. their fossil counterparts (PNG)

Sustainability & Health, Technology

1 Page

163 Downloads

163 Downloads

2022-08

FREE

Free Shipping163

DownloadsThis figure shows the climate change and resource use impact of PEF bottles versus PET bottles. nova-Institute’s peer-reviewed LCA evaluated 16 different impact categories covering all relevant life cycle stages from cradle-to-grave. The comparative analysis showed that PEF bottles would result in significant reductions in greenhouse gas emissions (-33%) compared to reference PET bottles. PEF would also lead to 45 % lower finite resource consumption of fossil fuels and reduce the pressure on abiotic resources (minerals and metals) by 47% due to the mechanical properties of PEF enabling light-weighting.

However, PET bottles would outperform PEF-bottles in other impact categories mostly arising from the current feedstock supply. Overall, this represents a benefit because climate change and resource use are among the most relevant environmental impact categories in the current political agenda as they are driving the transition from fossil to renewable carbon. Included in the nova-Institute’s LCA were next to 100% PEF bottles also 250 ml PET/PEF multilayer bottles with 10% of PEF compared to reference PET/PA bottles with a typical 7% of PA. The analysis of the multilayer bottles showed that significant reductions of around 37% in GHG emissions could be achieved by replacing the PA layer with PEF, mainly attributed to the recyclability of the PET/PEF system over the non-recyclability of the PA containing system. This replacement would also contribute to a significant reduction of finite resources demand (36% and 52% for fossils and minerals and metals respectively).

-

Erneuerbarer Kohlenstoff – Schlüssel zur Zukunft (PDF)

Policy, Sustainability & Health, Technology

2 Pages

346 Downloads

346 Downloads

2022-07

FREE

Free Shipping346

DownloadsDie chemische Industrie steht aktuell vor einer Vielzahl an Herausforderungen, aus denen eine neue, nachhaltige Chemie erwachsen kann – wenn die große Transformation in den nächsten Jahrzehnten gelingt. Und das muss sie!

Quelle: „Erneuerbarer Kohlenstoff – Schlüssel zur Zukunft“ – aus CHEManager 7/2022

https://www.chemanager-online.com/news/erneuerbarer-kohlenstoff-schluessel-zur-zukunft -

Mapping of advanced recycling – Providers, technologies, and partnerships – Short Version (PDF)

Technology

8 Pages

1419 Downloads

1419 Downloads

2022-06

FREE

Free Shipping1419

DownloadsAdvanced recycling technologies are developing at a fast pace, with new players constantly appearing on the market, from start-ups to giants and everything in between – new plants are being built, new capacities are being achieved, and new partnerships are established. Due to these developments, it is difficult to keep track of everything. The report “Mapping of advanced recycling technologies for plastics waste” aims to clear up this jungle of information providing a structured, in-depth overview and insight. It has an exclusive focus on profiling available technologies and providers of advanced recycling including the addition of new technologies and updated/revised profiles.

P.S.: All you want to know about advanced recycling technologies and renewable chemicals, building-blocks, monomers, and polymers based on recycling: Hear about it at the Advanced Recycling Conference (ARC), 28-29 November 2023, Cologne, Germany (hybrid event).

-

2022-06

2,500 € – 10,000 €Price range: 2,500 € through 10,000 € ex. tax

Plus 19% MwSt.Press

release Select

licenceAdvanced recycling technologies are developing at a fast pace, with new players constantly appearing on the market, from start-ups to giants and everything in between – new plants are being built, new capacities are being achieved, and new partnerships are established. Due to these developments, it is difficult to keep track of everything. The report “Mapping of advanced recycling technologies for plastics waste” aims to clear up this jungle of information providing a structured, in-depth overview and insight. It has an exclusive focus on profiling available technologies and providers of advanced recycling including the addition of new technologies and updated/revised profiles.

Further information:

The new report “Mapping of advanced recycling – Providers, technologies, and partnerships” differs from the old report “Chemical Recycling – Status, Trends and Challenges” as follows:

- All technology provider profiles from the old report included + updated to 2022.

- Overall >100 technologies and providers (vs. >70 technologies and providers in the old report)

- Extensive introductory part on polymer types, demand of different polymer types, waste fractions, political framework, position papers, technologies, LCAs, associations and waste management companies are no longer included in this report

In summary, this report is suitable for interested readers who have already dealt with the advanced recycling topic and are looking for an up-to-date overview of all identified providers and a detailed description of the technologies.

DOI No.: https://doi.org/10.52548/ITZE5668

P.S.: All you want to know about advanced recycling technologies and renewable chemicals, building-blocks, monomers, and polymers based on recycling: Hear about it at the Advanced Recycling Conference (ARC), 28-29 November 2023, Cologne, Germany (hybrid event).

-

Identified Advanced Recycling technology providers worldwide and maximum capacity (PNG)

Technology

1 Page

340 Downloads

340 Downloads

2022-06

FREE

Free Shipping340

DownloadsOverview about identified advanced recycling technology providers (blue bars) and maximum capacity (orange lines) depending on the technology.

-

897 Downloads

2022-06

FREE

Free Shipping897

DownloadsLife of a polymer from the production to its disposal (e.g. landfill) indicated with black arrows including various recycling and recovery routes indicated in different coloured arrows.

-

558 Downloads

2022-06

FREE

558

DownloadsAdvanced recycling technologies are developing at a fast pace, with new players constantly appearing on the market, from start-ups to giants and everything in between – new plants are being built, new capacities are being achieved, and new partnerships are established. Due to these developments, it is difficult to keep track of everything. The report “Mapping of advanced recycling technologies for plastics waste” aims to clear up this jungle of information providing a structured, in-depth overview and insight. It has an exclusive focus on profiling available technologies and providers of advanced recycling including the addition of new technologies and updated/revised profiles.

-

Renewable Materials Conference, 10-12 May 2022 (Proceedings)

Markets & Economy, Policy, Sustainability & Health, Technology

254 Downloads

254 Downloads

2022-05

FREE

Plus 19% MwSt.254

DownloadsThe proceedings of the Renewable Materials Conference (10-12 May 2022, https://renewable-materials.eu) contain conference presentations, the conference journal, and the press release of the three winners of the innovation award “Renewable Material of the Year”!

-

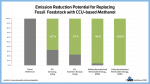

Emission Reduction Potential for Replacing Fossil Feedstock with CCU-based Methanol (PNG)

Sustainability & Health, Technology

1 Page

197 Downloads

197 Downloads

2022-05

FREE

197

DownloadsAt end of life, carbon embedded in chemicals and derived materials is released to the atmosphere as CO₂. In the case of fossil-based feedstock, this contributes to global warming. For CCU-based feedstock this is not the case, since all carbon embedded in these products was captured from the air (or from point sources) before through carbon capture. In a simplified model, additional emissions only electricity production for causes emissions for CCU-based feedstock production. Only the use of renewable energy can save emissions.

The GHG emissions of CCU-based methanol could be 67 to 77 % lower compared to emissions from releasing embedded carbon of fossil fuels, when using current energy supply based on photovoltaics. With improvements in renewable energy production, the reduction could increase to levels between 96 and 100 %. -

RCI’s scientific background report: “CO2 reduction potential of the chemical industry through CCU” (May 2022)

Sustainability & Health, Technology

28 Pages

1963 Downloads

1963 Downloads

2022-05

FREE

1963

DownloadsIn an exploratory scenario, this study investigates the CO₂ emission reductions that can be achieved in the global chemical and derived material industries if the entire demand for embedded carbon is met solely and exclusively via CO₂ instead of from fossil sources. Major simplifications are used to achieve transparency and comprehensibility of the issue. Methanol (CH3OH) is considered to cover the needs for hydrocarbons for chemicals and derived materials among the various chemical intermediates as a representative pathway for renewable carbon. It is a plausible scenario to assign methanol a central role in supplying the chemical industry of the future.

The GHG emissions of CCU-based methanol could be 67 to 77 % lower compared to emissions from releasing embedded carbon of fossil fuels, when using current energy supply based on photovoltaics. With improvements in renewable energy production, the reduction could increase to levels between 96 and 100 %.

DOI No.: https://doi.org/10.52548/UTRL5869

-

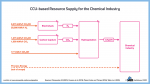

CCU-based Resource Supply for the Chemical Industry (PNG)

Sustainability & Health, Technology

1 Page

252 Downloads

252 Downloads

2022-05

FREE

252

DownloadsIt is a plausible scenario to assign methanol (CH₃OH) a central role in supplying the chemical industry of the future. Already today, methanol plays an important role in the chemical industry, being one of the most established commodities.

CCU-based process route for production of methanol includes production of hydrogen via electrolysis, CO₂ capture from the atmosphere or from industrial point sources, and the hydrogenation reaction. Electricity demand for these processes is represented by red arrows. Above the arrow, the specific energy demand is stated, below, the contribution of the process to the total electricity demand of 1 t of methanol is stated. Purification and compression of hydrogen are neglected. For CO₂ hydrogenation, a complete reaction is assumed.

![nova-Session: “Bio- and CO₂-based Polymers: Production, Trends 2022-2027 and the latest Policy Developments” (Proceedings, PDF) [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_1-100x141.png) nova-Session: “Bio- and CO₂-based Polymers: Production, Trends 2022-2027 and the latest Policy Developments” (Proceedings, PDF) [Digital]

nova-Session: “Bio- and CO₂-based Polymers: Production, Trends 2022-2027 and the latest Policy Developments” (Proceedings, PDF) [Digital]

![Cellulose Fibres Conference 2023 (Proceedings, PDF) [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_Cellulose-Fibres-100x141.png)

![Renewable Materials Conference, 10-12 May 2022 (Proceedings) [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_RMC-100x141.png)