Showing 1–20 of 104

-

Cellulose Fibres Conference 2024 (Proceedings, PDF)

Markets & Economy, Policy, Sustainability & Health, Technology

2024-04

150 € ex. tax

Plus 19% MwSt.Press

release Add to

cartThe conference covered the entire value chain, from lignocellulose, chemical pulp, cellulose fibres such as rayon, viscose, modal or lyocell and new developments to a wide range of applications:

Textiles from renewable fibres, non-wovens such as wet wipes as well as new areas such as composites, hygiene, packaging or nanocellulose in the food industry. The conference offered deep insights into the promising future of cellulose fibres, which perfectly fits the current trends of circular economy, recycling and sustainable carbon cycles.The Cellulose Fibres Conference Proceedings (https://cellulose-fibres.eu, 13-14 March 2024, Cologne, hybrid) include all released conference presentations, the conference journal, sponsor documents, a Fiber2Fashion Knowledgepaper and the conference press release.

-

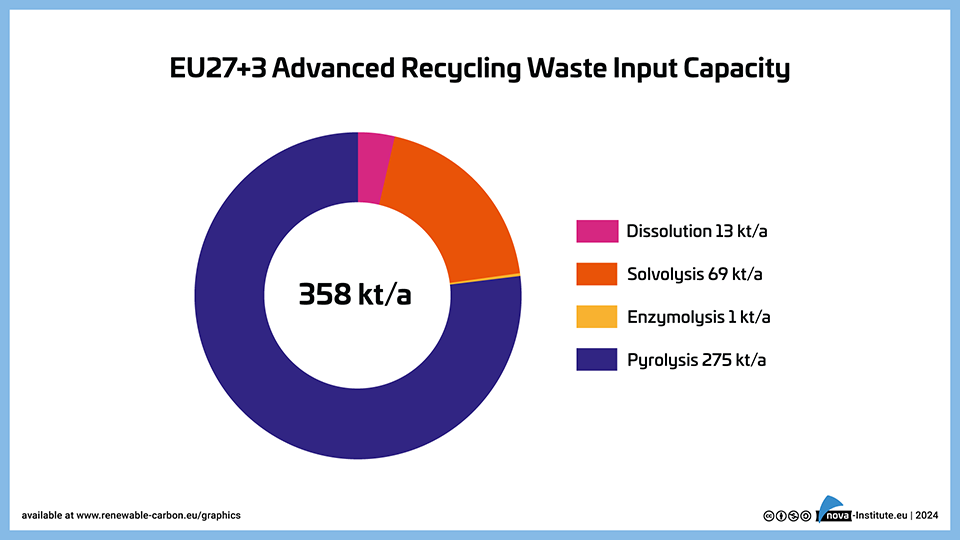

EU27+3 Advanced Recycling Waste Input Capacity (PNG)

Markets & Economy, Technology

1 Page

27 Downloads

27 Downloads

2024-03

FREE

27

DownloadsInstalled input capacities for different advanced recycling technologies in EU27+3.

-

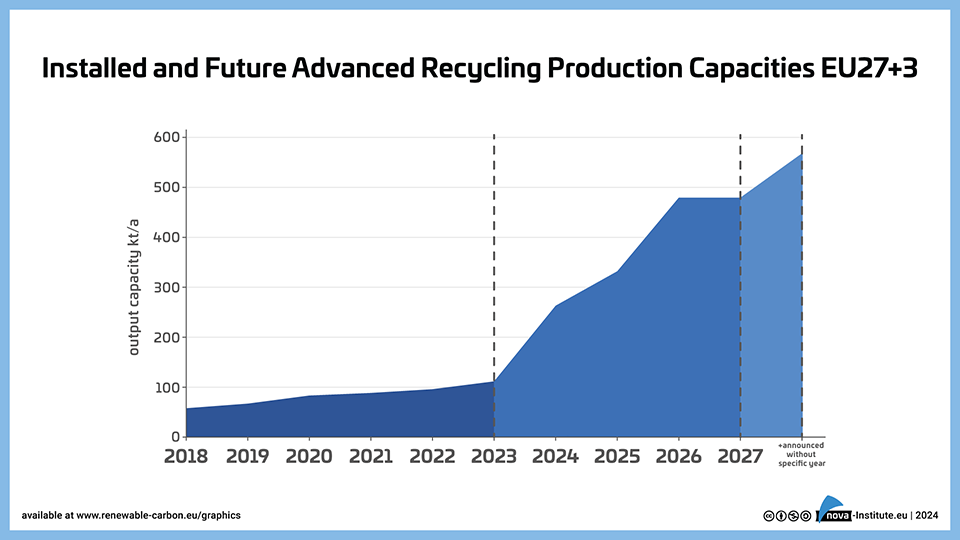

Installed and Future Advanced Recycling Production Capacities EU 27+3 (PNG)

Markets & Economy, Technology

1 Page

31 Downloads

31 Downloads

2024-03

FREE

31

DownloadsInstalled and future production capacities of naphtha, monomers and polymers through advanced recycling in the EU27+3.

-

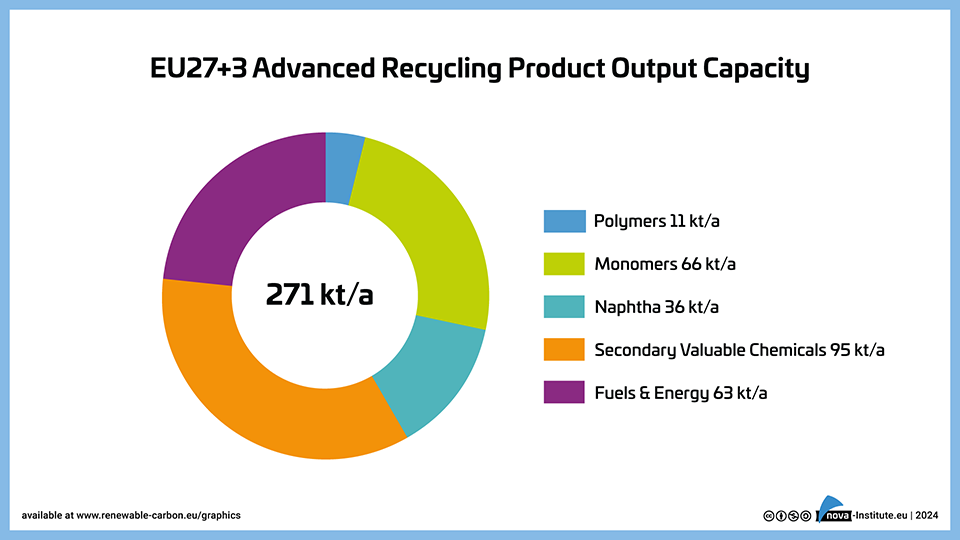

EU27+3 Advanced Recycling Product Output Capacity (PNG)

Markets & Economy, Technology

1 Page

24 Downloads

24 Downloads

2024-03

FREE

24

Downloads -

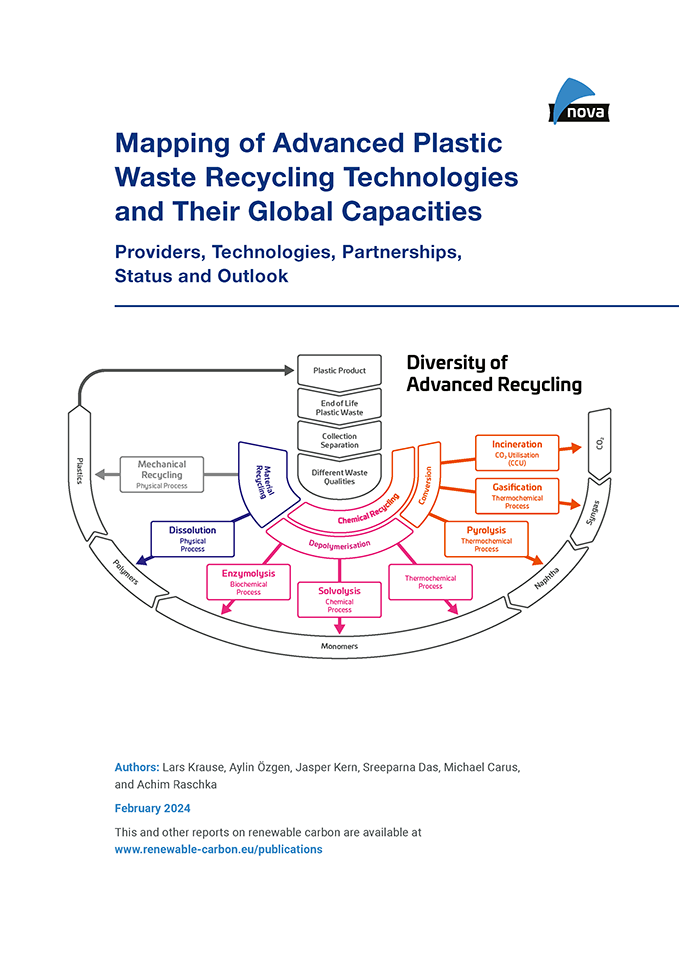

Mapping of advanced plastic waste recycling technologies and their global capacities (PDF)

NewMarkets & Economy, Technology

276 Pages

2024-02

3,000 € – 10,000 € ex. tax

Plus 19% MwSt.Select

licenceAdvanced recycling technologies are developing at a fast pace, with new players constantly appearing on the market, from start-ups to giants and everything in between – new plants are being built, new capacities are being achieved, and new partnerships are established. Due to these developments, it is difficult to keep track of everything. The report “Mapping of advanced plastic waste recycling technologies and their global capacities” aims to clear up this jungle of information providing a structured, in-depth overview and insight. It has an exclusive focus on profiling available technologies and providers of advanced recycling including the addition of new technologies and updated/revised profiles. Furthermore, for the first time a comprehensive evaluation of the global input and output capacities was carried out for which more than 340 planned as well as installed and operating plants including their specific product yields were mapped.

Further information:

The new report “Mapping of advanced plastic waste recycling technologies and their global capacities” differs from the old report “Chemical Recycling – Status, Trends and Challenges” as follows:- All technology provider profiles from the old report included + updated to 2023.

- Overall >120 technologies and providers (vs. >70 technologies and providers in the old report)

- Global capacities

In summary, this report is suitable for interested readers who have already dealt with the advanced recycling topic and are looking for an up-to-date overview of all identified providers and a detailed description of the technologies.

DOI No.: https://doi.org/10.52548/WQHT8696

-

Mapping of advanced plastic waste recycling technologies and their global capacities – Short Version (PDF)

NewMarkets & Economy, Technology

12 Pages

769 Downloads

769 Downloads

2024-02

FREE

769

DownloadsAdvanced recycling technologies are developing at a fast pace, with new players constantly appearing on the market, from start-ups to giants and everything in between – new plants are being built, new capacities are being achieved, and new partnerships are established. Due to these developments, it is difficult to keep track of everything. The report “Mapping of advanced plastic waste recycling technologies and their global capacities” aims to clear up this jungle of information providing a structured, in-depth overview and insight. It has an exclusive focus on profiling available technologies and providers of advanced recycling including the addition of new technologies and updated/revised profiles. Furthermore, for the first time a comprehensive evaluation of the global input and output capacities was carried out for which more than 340 planned as well as installed and operating plants including their specific product yields were mapped.

Further information:

The new report “Mapping of advanced plastic waste recycling technologies and their global capacities” differs from the old report “Chemical Recycling – Status, Trends and Challenges” as follows:- All technology provider profiles from the old report included + updated to 2023.

- Overall >120 technologies and providers (vs. >70 technologies and providers in the old report)

- Global capacities

In summary, this report is suitable for interested readers who have already dealt with the advanced recycling topic and are looking for an up-to-date overview of all identified providers and a detailed description of the technologies.

-

Advanced Recycling Conference 2023 (Proceedings)

Markets & Economy, Policy, Sustainability & Health, Technology

2023-12

150 € ex. tax

Plus 19% MwSt.Press

release Add to

cartThe proceedings of the Advanced Recycling Conference 2023 (28-29 November, https://advanced-recycling.eu) contain conference presentations, the conference journal, sponsor documents and the press release. Download of the conference journal incl. the program.

-

RCI’s scientific background report: “The use of food and feed crops for bio-based materials and the related effects on food security – Promoting evidence-based debates and recognising potential benefits” (June 2023) Short Version

Markets & Economy, Policy, Sustainability & Health, Technology

2 Pages

532 Downloads

532 Downloads

2023-11

FREE

532

DownloadsPromoting Evidence-based Debates and Recognising Potential Benefits

This short version of the scientific paper highlights on two pages new insights into a hotly debated topic and urges for careful and evidence-based debates.

The paper aims to show that the well-known biomass debate is flawed, subjective and not fully based on evidence. What is detrimental to food security are, according to the World Food Programme in 2023, climate change, conflict, extreme inequalities in wealth distribution, heavy dependence on food imports from industrial countries, overconsumption of meat, losses along the value chain and the impact of the COVID pandemic. Competition between biomass uses is not mentioned among the relevant causes.

The use of biomass for industrial applications, does have the potential to replace fossil feedstocks and thus contribute to the urgently needed reduction of fossil carbon emissions into our atmosphere to mitigate climate change.

While not denying the dire need to combat world hunger, the authors of the paper argue that using food and feed crops for chemicals and materials will not necessarily exacerbate food insecurity, and in fact has the potential to cause multiple benefits for local and global food security, climate mitigation and other factors:

- The climate wins – Bio-based materials are part of the solution to achieve climate change mitigation.

- Land productivity wins – The competition between applications is not for the type of crop grown, but for the land.

- The environment wins – due to increased resource efficiency and productivity of food and feed crops.

- Farmers win – because they have more options for selling stock to different markets.

- Market stability wins – due to increased global availability of food and feed crops.

- Feed security wins – due to the high value of the protein-rich co-products of food and feed crops.

- Food security wins – due to the increased overall availability of edible crops that can be stored and flexibly distributed.

-

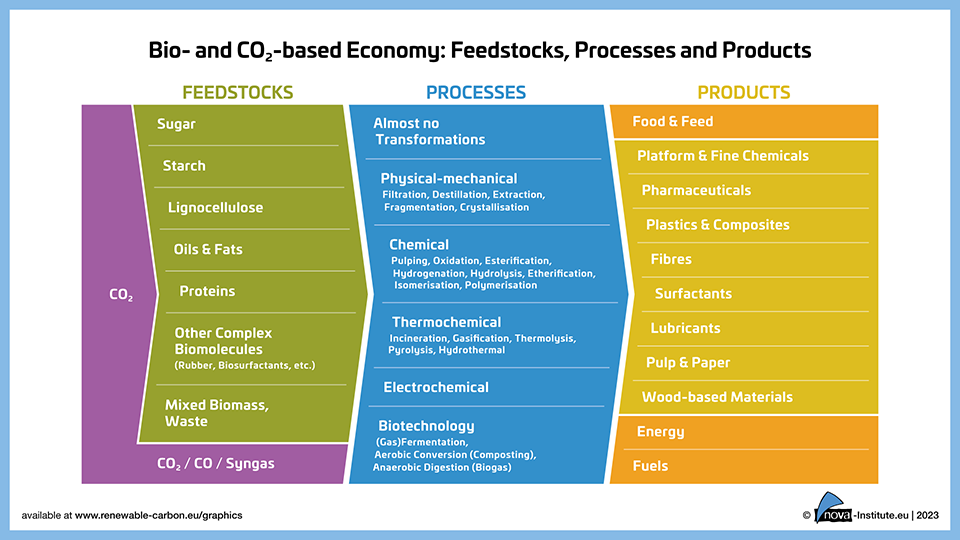

“Bio- and CO2-based Economy: feedstocks, processes and products” − Graphic – Update

Markets & Economy, Sustainability & Health, Technology

1 Page

3067 Downloads

3067 Downloads

2023-09

FREE

3067

Downloads -

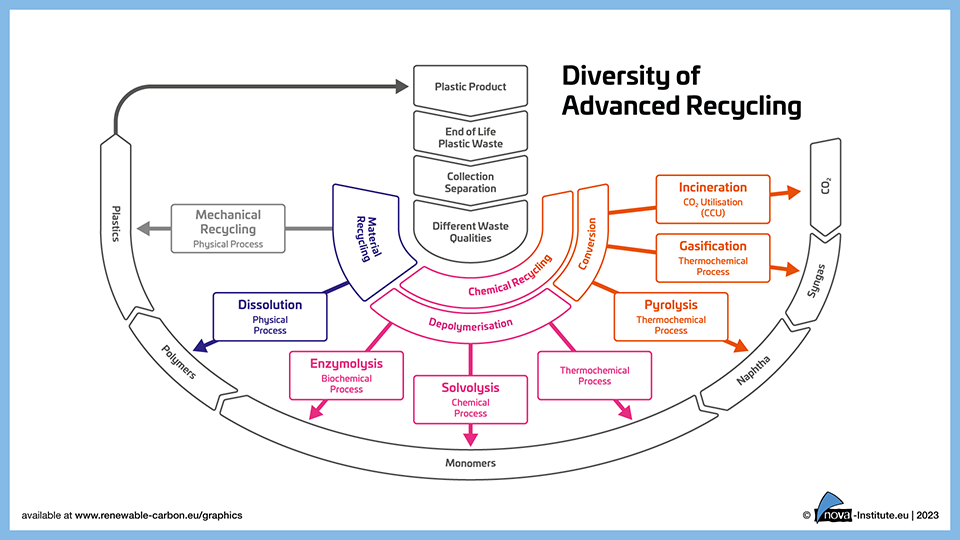

1013 Downloads

2023-07

FREE

Free Shipping1013

DownloadsFull spectrum of available recycling technologies divided by their basic working principles and their products.

-

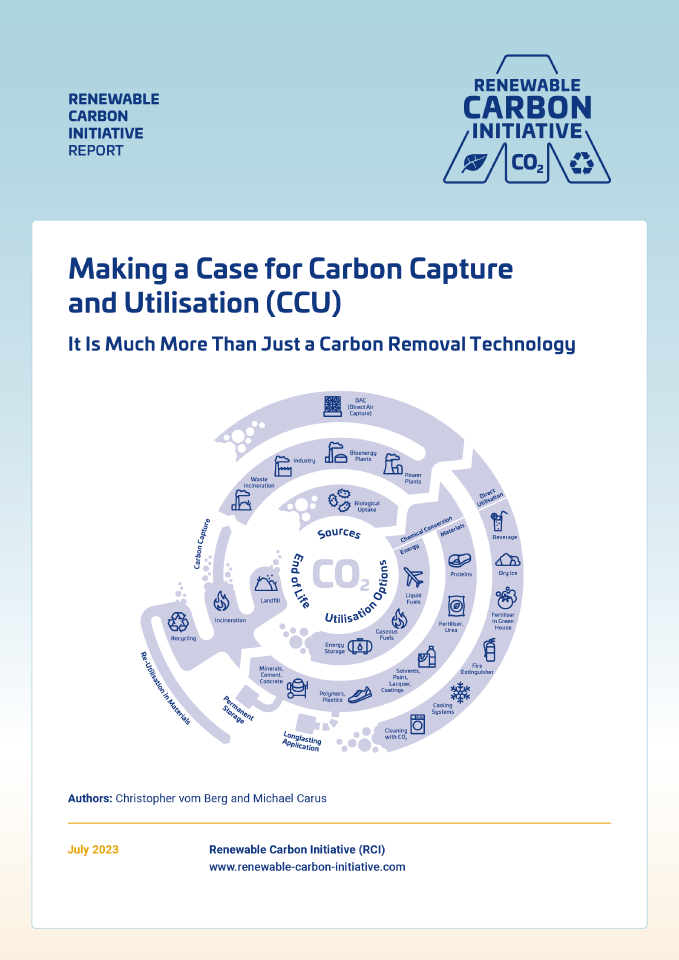

RCI’s scientific background paper: “Making a case for Carbon Capture and Utilisation (CCU) – It is much more than just a carbon removal technology” (July 2023)

Markets & Economy, Policy, Sustainability & Health, Technology

48 Pages

1446 Downloads

1446 Downloads

2023-07

FREE

Free Shipping1446

DownloadsThis scientific background paper highlights the importance of Carbon Capture and Utilisation (CCU) and the need for more political recoginition and support for CCU.

CCU enables the substitution of fossil carbon in sectors where carbon is necessary, supports the full defossilisation of the chemical and derived material industries, creates a circular economy, reduces the emission gap, promotes sustainable carbon cycles, fosters innovation, generates local value and stimulates job growth.

CCU is much more than a carbon removal technology: the technology offers multiple solutions to pressing problems of our modern world and can support several Sustainable Development Goals if implemented properly.

In total, 14 different benefits and advantages of CCU are described and discussed in the paper. A key advantage is that CCU supplies renewable carbon to – and thereby substitutes fossil carbon in – sectors that will require carbon in the long run. This includes the chemical sectors and products like polymers, plastics, solvents, paints, detergents, cosmetics or pharmaceuticals. But CCU is also essential to a long-term net-zero strategy, crucial for creating a sustainable circular economy, providing solutions for scaling up the renewable energy system, and bringing multiple benefits for innovation and business.

The relevance of the technology is not yet accepted in Europe, but the RCI wants to make a very clear statement: CCU is a central pillar for the biggest transformation of the chemical and material industry since the industrial revolution.

DOI No.: https://doi.org/10.52548/VYKR3129

-

RCI’s scientific background report: “The use of food and feed crops for bio-based materials and the related effects on food security – Promoting evidence-based debates and recognising potential benefits” (June 2023) Long Version

Markets & Economy, Policy, Sustainability & Health, Technology

36 Pages

1121 Downloads

1121 Downloads

2023-06

FREE

1121

DownloadsPromoting Evidence-based Debates and Recognising Potential Benefits

This scientific paper highlights new insights into a hotly debated topic and urges for careful and evidence-based debates.

The paper aims to show that the well-known biomass debate is flawed, subjective and not fully based on evidence. What is detrimental to food security are, according to the World Food Programme in 2023, climate change, conflict, extreme inequalities in wealth distribution, heavy dependence on food imports from industrial countries, overconsumption of meat, losses along the value chain and the impact of the COVID pandemic. Competition between biomass uses is not mentioned among the relevant causes.

The use of biomass for industrial applications, does have the potential to replace fossil feedstocks and thus contribute to the urgently needed reduction of fossil carbon emissions into our atmosphere to mitigate climate change.

While not denying the dire need to combat world hunger, the authors of the paper argue that using food and feed crops for chemicals and materials will not necessarily exacerbate food insecurity, and in fact has the potential to cause multiple benefits for local and global food security, climate mitigation and other factors:

- The climate wins – Bio-based materials are part of the solution to achieve climate change mitigation.

- Land productivity wins – The competition between applications is not for the type of crop grown, but for the land.

- The environment wins – due to increased resource efficiency and productivity of food and feed crops.

- Farmers win – because they have more options for selling stock to different markets.

- Market stability wins – due to increased global availability of food and feed crops.

- Feed security wins – due to the high value of the protein-rich co-products of food and feed crops.

- Food security wins – due to the increased overall availability of edible crops that can be stored and flexibly distributed.

DOI No.: https://doi.org/10.52548/WQXU7327

-

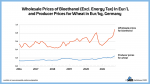

Wholesale Prices of Bioethanol and Wheat (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

62 Downloads

62 Downloads

2023-06

FREE

62

Downloads -

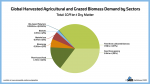

Global Harvested Agricultural and Grazed Biomass Demand by Sectors (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

103 Downloads

103 Downloads

2023-06

FREE

103

Downloads -

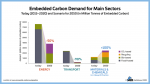

Embedded Carbon Demand for Main Sector (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

96 Downloads

96 Downloads

2023-06

FREE

96

Downloads -

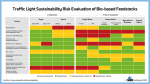

Traffic Light Sustainability Risk Evaluation of Bio-based Feedstocks (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

210 Downloads

210 Downloads

2023-06

FREE

210

Downloads -

Corn and its Applications (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

92 Downloads

92 Downloads

2023-06

FREE

92

Downloads -

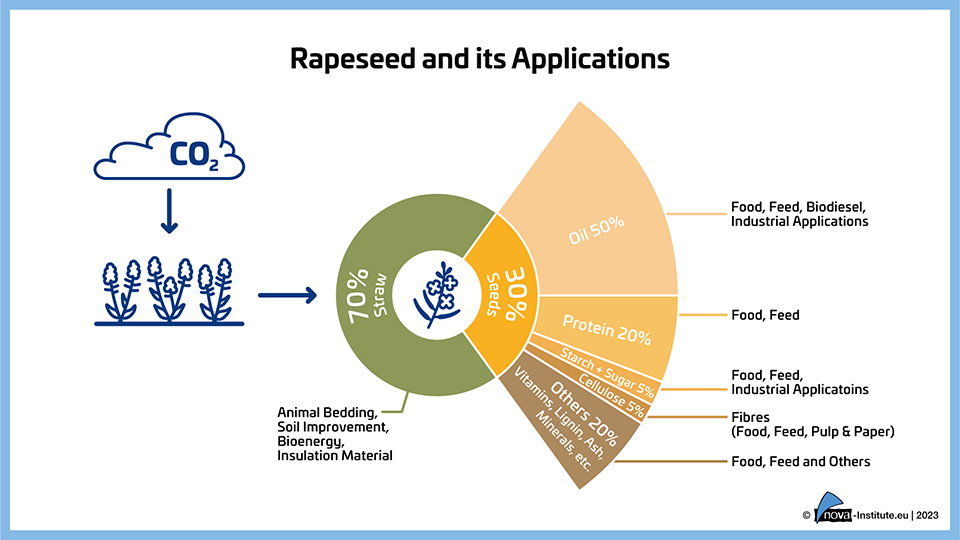

Rapeseed and its Applications (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

64 Downloads

64 Downloads

2023-06

FREE

64

Downloads -

Yield of Fermentable Sugars (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

104 Downloads

104 Downloads

2023-06

FREE

104

Downloads -

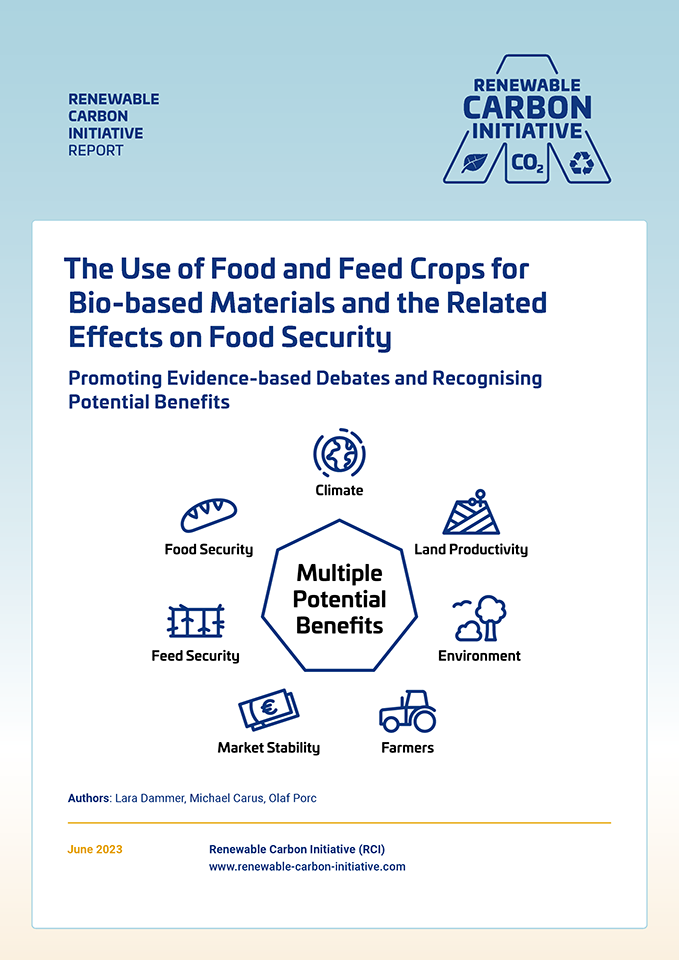

Graphic of the scientific paper „The Use of Food and Feed Crops for Bio-based Materials and the Related Effects on Food Security“ (PNG)

Markets & Economy, Policy, Sustainability & Health, Technology

1 Page

81 Downloads

81 Downloads

2023-06

FREE

81

DownloadsPromoting Evidence-based Debates and Recognising Potential Benefits

The graphic shows the multiple potential benefits of using food and feed crops for bio-based materials, in terms of climate, land productivity, environment, farmers, market stability, feed security and food security.

- The climate wins – Bio-based materials are part of the solution to achieve climate change mitigation.

- Land productivity wins – The competition between applications is not for the type of crop grown, but for the land

- The environment wins – due to increased resource efficiency and productivity of food and feed crops.

- Farmers win – because they have more options for selling stock to different markets.

- Market stability wins – due to increased global availability of food and feed crops.

- Feed security wins – due to the high value of the protein-rich co-products of food and feed crops.

- Food security wins – due to the increased overall availability of edible crops that can be stored and flexibly distributed.