Showing 121–140 of 240

-

nova-Session “Life Cycle Assessment (LCA) in Science and Policy” (Proceedings)

Sustainability & Health

2 Downloads

2 Downloads

2022-10

FREE

Plus 19% MwSt.2

DownloadsThe download of the proceedings contains all eight presentations.

This nova-Session (September 2022 and October 2022) discussed the important tool of Life Cycle Assessment (LCA) – its scientific and methodological principles as well as practical implementation in political decision-making.

Assessing and comparing products’ environmental performances is a critical element in transforming our economic system towards sustainability and mitigating climate change. How else to make decisions as to which technologies, feedstocks or production systems are preferable?

LCA according to ISO 14040 has become the most widely accepted and applied method to provide information on products’ and companies’ environmental performance.

As a standardised tool it offers many advantages such as credibility and comparability.However, it also offers flexibility to cover a multitude of products, companies and processes. This has the advantage that it can be adapted to all kinds of circumstances, but it also reduces comparability and there is a certain danger of greenwashing. Therefore, higher comparability has been a goal of LCA method development for quite some time. Recently, policy also has been referring more and more to LCA to provide guidelines, support, incentives or permits. These need fixed values and comparable results – so the longer intended method development is imperative now. Accordingly, there have been increased efforts to build on the LCA method for political purposes and develop common assumptions, comparators and default values for product groups. Prominent examples are the calculation rules for biofuels, the discussions about the Product Environmental Footprint (PEF), LCA calculations for bio-based plastics, GHG emissions of recycled plastics and for fuels made from CCU, discussions in the framework of the Taxonomy and more.

-

156 Downloads

2022-08

FREE

Free Shipping156

DownloadsPEF has enhanced barrier, mechanical and thermal properties compared to today’s widely used

petroleum-based polymers. The barrier properties of PEF, which are ~10x better for O2, ~15x better

for CO2 and ~2.5x better for water than PET, represent a revolutionary opportunity compared with traditional packaging solutions regarding performance, price, and sustainability when produced at scale. The improved barrier properties lead to a longer shelf life of packaged products. PEF also offers higher mechanical strength, which means that thinner PEF packaging can be produced and fewer resources are required.

In terms of thermal properties, PEF has superior ability to withstand heat and can be processed at lower temperatures. PEF has enhanced mechanical stiffness and allows for increasing shaping possibilities. -

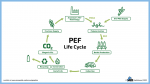

Life cycle stages of monolayer PEF bottles (PNG)

Sustainability & Health, Technology

1 Page

134 Downloads

134 Downloads

2022-08

FREE

Free Shipping134

DownloadsThis figure shows the relevant life cycle stages of monolayer PEF bottles from cradle-to-grave: from the biomass cultivation (wheat for fructose and sugarcane for bio-MEG feedstocks supply) to the production of PEF-based bottles including their end-of-life options (recycling and incineration).

It is foreseen that the commercialisation of PEF-based products will initially take place in the Netherlands, Belgium, and Germany. In these countries, the rates for average PET bottle waste collection and recycling are relatively high and landfilling is no longer practiced in these countries. -

PEF – A Sustainable Packaging Material for Bottles (PDF)

Sustainability & Health, Technology

14 Pages

799 Downloads

799 Downloads

2022-08

FREE

Free Shipping799

DownloadsThe chemical technology company Avantium (NL) partnered with nova-Institut GmbH under the framework of the PEFerence project, to perform a full cradle-to-grave Life Cycle Assessment (LCA) for the YXY® Technology, assessing the potential environmental impacts of PEF packaging solutions in comparison to conventional PET packaging. The LCA is performed according to the ISO 14040/44 standard methodology. A critical peer review of the study, including experts of incumbent technologies, was conducted in order to verify whether the LCA met the requirements for methodology, data, interpretation, and reporting. This brochure summarizes the main aspects about the environmental sustainability of PEF-based bottles.

-

Environmental impacts of 250 ml monolayer and PET/PEF multilayer bottles vs. their fossil counterparts (PNG)

Sustainability & Health, Technology

1 Page

154 Downloads

154 Downloads

2022-08

FREE

Free Shipping154

DownloadsThis figure shows the climate change and resource use impact of PEF bottles versus PET bottles. nova-Institute’s peer-reviewed LCA evaluated 16 different impact categories covering all relevant life cycle stages from cradle-to-grave. The comparative analysis showed that PEF bottles would result in significant reductions in greenhouse gas emissions (-33%) compared to reference PET bottles. PEF would also lead to 45 % lower finite resource consumption of fossil fuels and reduce the pressure on abiotic resources (minerals and metals) by 47% due to the mechanical properties of PEF enabling light-weighting.

However, PET bottles would outperform PEF-bottles in other impact categories mostly arising from the current feedstock supply. Overall, this represents a benefit because climate change and resource use are among the most relevant environmental impact categories in the current political agenda as they are driving the transition from fossil to renewable carbon. Included in the nova-Institute’s LCA were next to 100% PEF bottles also 250 ml PET/PEF multilayer bottles with 10% of PEF compared to reference PET/PA bottles with a typical 7% of PA. The analysis of the multilayer bottles showed that significant reductions of around 37% in GHG emissions could be achieved by replacing the PA layer with PEF, mainly attributed to the recyclability of the PET/PEF system over the non-recyclability of the PA containing system. This replacement would also contribute to a significant reduction of finite resources demand (36% and 52% for fossils and minerals and metals respectively).

-

296 Downloads

2022-08

FREE

Free Shipping296

DownloadsAvantium has developed a technology to convert plant-based sugars into FDCA (furandicarboxylic acid), the building block of PEF (polyethylene furanoate): a plant-based, fully recyclable polymer with superior performance. FDCA is polymerised with plant-based mono-ethylene glycol (MEG) to make a 100% plant-based PEF polymer. In December 2021, Avantium has taken a positive investment decision concerning the construction of the world’s first FDCA Flagship Plant in Delfzijl (The Netherlands), with construction planned to be completed by the end of 2023 and the aim to be operational in 2024. This will be the world’s first commercial FDCA facility and will have a targeted production capacity of 5,000 tonnes per annum. FDCA is the key building block for the 100% plant-based, recyclable polymer PEF.

-

Erneuerbarer Kohlenstoff – Schlüssel zur Zukunft (PDF)

Policy, Sustainability & Health, Technology

2 Pages

346 Downloads

346 Downloads

2022-07

FREE

Free Shipping346

DownloadsDie chemische Industrie steht aktuell vor einer Vielzahl an Herausforderungen, aus denen eine neue, nachhaltige Chemie erwachsen kann – wenn die große Transformation in den nächsten Jahrzehnten gelingt. Und das muss sie!

Quelle: „Erneuerbarer Kohlenstoff – Schlüssel zur Zukunft“ – aus CHEManager 7/2022

https://www.chemanager-online.com/news/erneuerbarer-kohlenstoff-schluessel-zur-zukunft -

nova-paper #16: The Biomass Utilisation Factor (BUF)

Markets & Economy, Policy, Sustainability & Health

62 Pages

1466 Downloads

1466 Downloads

2022-06

FREE

1466

DownloadsThe Biomass Utilisation Factor (BUF) is a new metric combining cascading use and production efficiency into one indicator to investigate the circularity of materials for the circular bioeconomy. Cascading use captures the repeated use of the original biomass, either for the same or a different purpose. Production efficiency looks at how much of the biomass input is actually transformed into useful products or materials.

The BUF can serve not only as an indicator for the circular economy principle of keeping materials in use, but also act as an efficient tool for stakeholders and policy makers to identify options that maximize biomass utilisation and keep materials in use for longer. In light of recent political developments in Europe, the BUF can serve as a tool that provides additional insights for achieving sustainable carbon cycles or help to respect the cascading principle of biomass utilisation.

-

Die neue Tugend: Kunststoff im Kreislauf (PDF)

Markets & Economy, Policy, Sustainability & Health

1 Page

293 Downloads

293 Downloads

2022-05

FREE

293

DownloadsRohstoffe werden knapp, sowohl Metalle wie auch Mineralien. Nur erneuerbarer Kohlenstoff ist praktisch unbegrenzt verfügbar. Daher werden Kunststoffe in Zukunft noch wichtiger sein als heute, und deshalb müssen sie so nachhaltig wie möglich gestaltet werden: aus erneuerbarem Kohlenstoff und voll recycelbar.

-

Renewable Materials Conference, 10-12 May 2022 (Proceedings)

Markets & Economy, Policy, Sustainability & Health, Technology

254 Downloads

254 Downloads

2022-05

FREE

Plus 19% MwSt.254

DownloadsThe proceedings of the Renewable Materials Conference (10-12 May 2022, https://renewable-materials.eu) contain conference presentations, the conference journal, and the press release of the three winners of the innovation award “Renewable Material of the Year”!

-

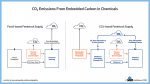

CO₂ Emissions From Embedded Carbon in Chemicals (PNG)

Sustainability & Health, Technology

1 Page

303 Downloads

303 Downloads

2022-05

FREE

303

DownloadsWhen fossil feedstock is used, the fossil-based embedded carbon contained in chemicals and materials is emitted to the atmosphere at their end of life, assuming complete oxidation (e.g. through combustion or (bio)degradation).

When using CCU-based feedstock to replace the fossil feedstock, at the end of life, no additional carbon (or CO2, respectively) is emitted to the air because it was captured from the air (or from point sources) before through carbon capture. Only the electricity demand for CCU-based feedstock production causes CO2 emissions.

-

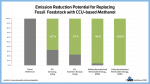

Emission Reduction Potential for Replacing Fossil Feedstock with CCU-based Methanol (PNG)

Sustainability & Health, Technology

1 Page

197 Downloads

197 Downloads

2022-05

FREE

197

DownloadsAt end of life, carbon embedded in chemicals and derived materials is released to the atmosphere as CO₂. In the case of fossil-based feedstock, this contributes to global warming. For CCU-based feedstock this is not the case, since all carbon embedded in these products was captured from the air (or from point sources) before through carbon capture. In a simplified model, additional emissions only electricity production for causes emissions for CCU-based feedstock production. Only the use of renewable energy can save emissions.

The GHG emissions of CCU-based methanol could be 67 to 77 % lower compared to emissions from releasing embedded carbon of fossil fuels, when using current energy supply based on photovoltaics. With improvements in renewable energy production, the reduction could increase to levels between 96 and 100 %. -

RCI’s scientific background report: “CO2 reduction potential of the chemical industry through CCU” (May 2022)

Sustainability & Health, Technology

28 Pages

1960 Downloads

1960 Downloads

2022-05

FREE

1960

DownloadsIn an exploratory scenario, this study investigates the CO₂ emission reductions that can be achieved in the global chemical and derived material industries if the entire demand for embedded carbon is met solely and exclusively via CO₂ instead of from fossil sources. Major simplifications are used to achieve transparency and comprehensibility of the issue. Methanol (CH3OH) is considered to cover the needs for hydrocarbons for chemicals and derived materials among the various chemical intermediates as a representative pathway for renewable carbon. It is a plausible scenario to assign methanol a central role in supplying the chemical industry of the future.

The GHG emissions of CCU-based methanol could be 67 to 77 % lower compared to emissions from releasing embedded carbon of fossil fuels, when using current energy supply based on photovoltaics. With improvements in renewable energy production, the reduction could increase to levels between 96 and 100 %.

DOI No.: https://doi.org/10.52548/UTRL5869

-

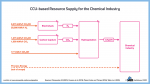

CCU-based Resource Supply for the Chemical Industry (PNG)

Sustainability & Health, Technology

1 Page

252 Downloads

252 Downloads

2022-05

FREE

252

DownloadsIt is a plausible scenario to assign methanol (CH₃OH) a central role in supplying the chemical industry of the future. Already today, methanol plays an important role in the chemical industry, being one of the most established commodities.

CCU-based process route for production of methanol includes production of hydrogen via electrolysis, CO₂ capture from the atmosphere or from industrial point sources, and the hydrogenation reaction. Electricity demand for these processes is represented by red arrows. Above the arrow, the specific energy demand is stated, below, the contribution of the process to the total electricity demand of 1 t of methanol is stated. Purification and compression of hydrogen are neglected. For CO₂ hydrogenation, a complete reaction is assumed.

-

Conference on CO2-based Fuels and Chemicals 2022 Proceedings

Markets & Economy, Policy, Sustainability & Health, Technology

110 Downloads

110 Downloads

2022-04

FREE

Plus 19% MwSt.110

DownloadsThe proceedings of the Conference on CO2-based Fuels and Chemicals 2022 (23-24 March 2022, https://co2-chemistry.eu) contain 26 presentations, the conference journal, and the press release of the three winners of the Innovation Award “Best CO2 Utilisation 2022“.

-

International Conference on Cellulose Fibres 2022 Proceedings

Markets & Economy, Policy, Sustainability & Health, Technology

174 Downloads

174 Downloads

2022-02

FREE

Plus 19% MwSt.174

DownloadsThe proceedings of the International Conference on Cellulose Fibres 2022 (2-3 February 2022, https://cellulose-fibres.eu) contain 26 presentations, the conference journal, and the press release of the three winners of the Cellulose Fibre Innovation of the Year 2021 Award!

-

RCI’s scientific background report: “Renewable carbon as a guiding principle for sustainable carbon cycles” (February 2022)

Policy, Sustainability & Health

41 Pages

2973 Downloads

2973 Downloads

2022-02

FREE

2973

DownloadsWhy it is right to choose renewable carbon as a guiding principle for sustainable development in the chemicals and materials sectors.

The Renewable Carbon Initiative (RCI) publishes this fundamental strategy paper on the defossilisation of the chemical and material industry with eleven policy recommendations. The Renewable Carbon Initiative is an interest group of more than 30 well-known companies from the wide field of the chemical and material value chains. (www.renewable-carbon-initiative.com)Read more here: https://renewable-carbon-initiative.com/media/press/?id=315

DOI No.: https://doi.org/10.52548/QUHG1295

-

The Climate Change Mitigation Star: A Sixfold Challenge (PNG)

Policy, Sustainability & Health

1 Page

178 Downloads

178 Downloads

2022-02

FREE

178

DownloadsWhy it is right to choose renewable carbon as a guiding principle for sustainable development in the chemicals and materials sectors.

The Renewable Carbon Initiative (RCI) publishes this fundamental strategy paper on the defossilisation of the chemical and material industry with eleven policy recommendations. The Renewable Carbon Initiative is an interest group of more than 30 well-known companies from the wide field of the chemical and material value chains. (www.renewable-carbon-initiative.com)Read more here: https://renewable-carbon-initiative.com/media/press/?id=315

-

Das wechselhafte Image der Kunststoffe: Von Begeisterung zur Skepsis, vom Siegeszug zum Umweltproblem (PDF)

Markets & Economy, Sustainability & Health

2 Pages

263 Downloads

263 Downloads

2022-01

FREE

263

DownloadsDas Image der Kunststoffe steht heute in der Krise. Wie konnte es so weit kommen und was kann man tun, um das Image wieder zu verbessern? Kunststoffe sind wichtiger denn je für eine nachhaltige Zukunft. Alle Technologien stehen zur Verfügung, um Kunststoffe umweltfreundlich zu gestalten und im Kreislauf zu fahren. Wie können wir die Gesellschaft wieder davon überzeugen, dass eine Welt mit den richtigen Kunststoffen komfortabler, ressourcenschonender und klimafreundlicher sein wird als ohne?

-

Biodegradable Polymers in Various Environments According to Established Standards and Certification Schemes – Graphic (PNG, Version 2021)

Sustainability & Health, Technology

1 Page

1936 Downloads

1936 Downloads

2021-11

FREE

Free Shipping1936

DownloadsNew updated version of the poster on Biodegradable Polymers in Various Environments According to Established Standards and Certification Schemes

The popular poster has been once again updated this autumn to depict to most up-to-date status of commercially available polymers which actually biodegrade in accordance with established standards and certification schemes. An additional partner rounds up this team of leading experts in the area of biodegradable polymers.

![nova-Session "Life Cycle Assessment (LCA) in Science and Policy" (Proceedings) [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_1-100x141.png)

![Renewable Materials Conference, 10-12 May 2022 (Proceedings) [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_RMC-100x141.png)

![Conference on CO2-based Fuels and Chemicals 2022 Proceedings [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_CO2-based-100x141.png)

![International Conference on Cellulose Fibres 2022 Proceedings [Digital]](https://renewable-carbon.eu/publications/wp-content/uploads/2020/05/21-01-07_RC-Publications-Cover-Proceedings_Cellulose-Fibres-100x141.png)