The project MIX-UP (MIXed plastics biodegradation and UPcycling using microbial communities), which receives funding from the European Union’s Horizon 2020 research and innovation programme and the National Science Foundation of China, started on the 1st of January 2020. The main idea of MIX-UP is to showcase a novel approach for plastic recycling and therefore addresses one of the greatest challenges of our time: the establishment of a circular (bio)-economy for plastics. The ground-breaking objective is – plastic waste to plastic value – by a biotechnological conversion of unsorted, mixed plastics into valuable bioplastic using heavily engineered enzyme mixtures and mixed microbial communities.

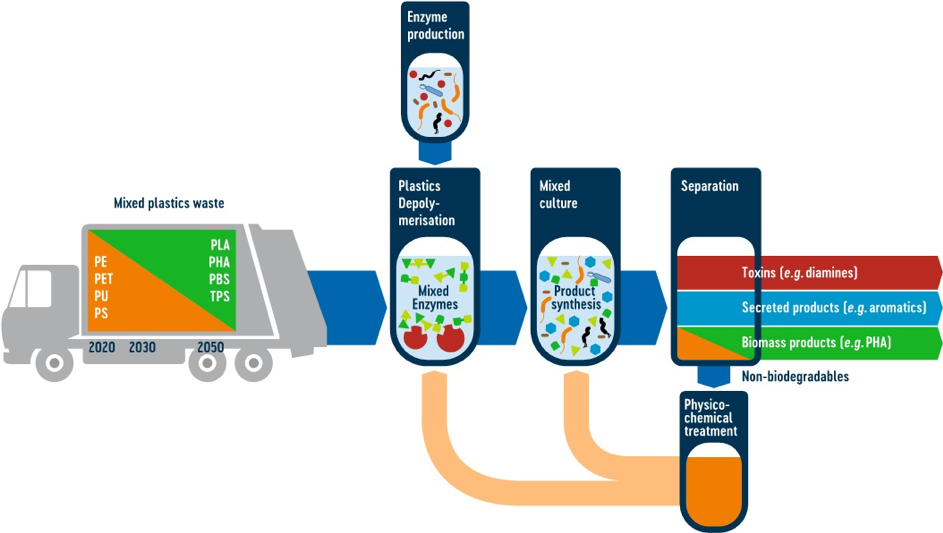

First, unsorted plastic waste needs to be mechanically pre-treated. A further preliminary step before the actual upcycling is to produce enzymes in defined microbial mixed cultures and synthesised in an optimised production reactor (enzyme production). Next, the shredded waste is exposed to those engineered, enzyme blends to hydrolyse the polymers into their smaller components (mono- and oligomers). For this first and essential step (plastic depolymerisation), a mixture of dedicated enzymes is required that can handle the different types of plastic present.

The released plastic mono- and oligomers from the various plastics-types are transferred to a mixed culture bioreactor. Here, these mono- and oligomers can be used as plastic derived feedstock and fed to dedicated microbial communities, able to bioconvert these components into new components. Afterwards, these new components provide building blocks for the synthesis of novel biopolymers, e.g. bioplastics like the polyhydroxyalkanoates / PHA.

Besides the bioplastics, toxins and other secreted products are released during the upcycling process. Therefore, MIX-UP will tackle the issue of downstream processing and recovery of the product by, for example, conditional release of the intracellular products and their separation. The plastics waste recalcitrant residues will be subjected to chemical transformations (physio-chemical treatment), thereby synthesising valuable chemicals and closing the MIX-UP cycle by re-entering into the bioprocess.

Through a combination of intensive protein engineering, metabolic engineering of defined mixed cultures and bioprocess-optimisation, MIX-UP will enable new value chains across sectors like materials, chemicals, and environmental technologies within the framework of a sustainable, knowledge-based bio-economy. MIX-UP will ultimately be to the benefit of the economy, environment, and society at large.

Partners at RWTH Aachen University are Professors Lars M. Blank (iAMB, coordinator), Ulrich Schwaneberg (BIOTEC), Jürgen Klankermayer (ITMC), and Andreas Jupke (AVT). External partners include the Spanish National Research Council (CSIC), University College Dublin, University of Greifswald, SOPREMA, Forschungszentrum Jülich, Bioplastech Ltd, National Center for Scientific Research (CNRS), Everwave GmbH (Aachen), AB Enzymes GmbH (Darmstadt), and from China Nanjing Tech University (coordinator NSFC-part), Beijing University of Chemical Technology, Institute of Process Engineering – Chinese Academy of Sciences, and Tsinghua University.

This project receives funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement number 870294 and from the National Science Foundation of China under grant numbers 31961133017, 31961133018, 31961133019.

Source

MIX-UP, press release, 2020-11-17.

Supplier

AB Enzymes

BIOTEC GmbH & Co. KG

Centre national de la recherche scientifique (CNRS)

Chinese Academy of Sciences (CAS)

Forschungszentrum Jülich

Französisches Zentrum für wissenschaftliche Forschung (CNRS)

Nanjing Tech University

Rheinisch-Westfälische Technische Hochschule Aachen (RWTH)

SOPREMA Group

Spanish National Research Council (CSIC)

Tsinghua University

Universität Greifswald

University College Dublin (UCD)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals