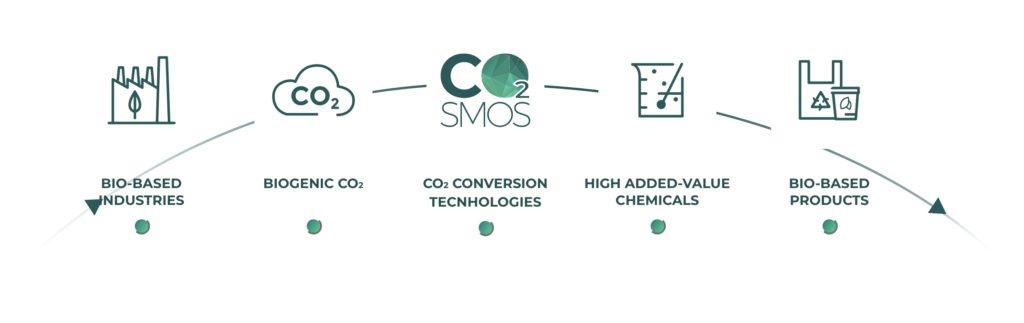

The European-funded CO₂SMOS project officially concludes this month after four years of collaborative research and innovation aimed at supporting the bio-based industry in reducing its carbon footprint. With €7 million in funding from the Horizon 2020 programme, the project has developed and scaled technologies that convert biogenic CO₂ emissions into valuable chemicals and materials, bringing them closer to real-world application.

Launched in May 2021, CO₂SMOS (Advanced chemicals production from biogenic CO₂ emissions for circular bio-based industries) brought together a multidisciplinary consortium of 15 partners from across Europe, coordinated by CARTIF Technology Center. The aim was to develop cost-competitive technologies for transforming CO₂ emissions from bio-industrial processes into renewable chemicals, durable polymers, and biodegradable biomaterials, contributing to Europe’s climate goals and the development of a sustainable circular economy.

Turning Biogenic CO₂ Into Valuable Products

CO₂SMOS focused on technologies that transform biogenic CO₂, generated from processes such as fermentation, into intermediate building blocks like acetate, syngas, and other valuable compounds. These were then used to create renewable polymers, biochemicals, and biodegradable materials. Key achievements include:

- Biotechnological and Electrocatalytic CO₂ Conversion: Lab-scale innovations included the biological production of bio-acetate using acetogenic bacteria and the electrocatalytic generation of green syngas and intermediates. In the first lab-scale approach, continuous fermentation processes were scaled up to 10L, successfully producing acetate at industrially relevant titers.

- Synthesis of Monomers and Intermediates: Novel catalysts and microbial strains enabled the transformation of CO₂-derived acetic acid into value-added monomers such as PHB, PHA, and 2,3-BDO, as well as the cycloaddition of CO₂ to biomass derivatives to produce cyclic carbonates with potential as plasticisers. Physicochemical approaches delivered efficient separation and purification processes, including solid electrolyte reactors and advanced membrane technologies.

- Pilot-Scale Success: At the Bio Base Europe Pilot Plant, several of the project’s CO₂-based value chains were successfully scaled. CO₂-derived acetic acid was used to produce kilograms of high-purity PHB, while mcl-PHA was generated at a 150L scale, surpassing industry benchmarks. These materials were then validated in industrial applications.

From Innovation to Real-World Applications

The three end users within the consortium demonstrated the practical potential of the materials derived from CO₂SMOS technologies:

- Novamont used PHAs produced from biogenic CO₂ to develop, among others, compostable films for packaging. These materials showed good thermal stability and mechanical performance while meeting strict biodegradability standards.

- Avantium used 2,3-BDO as a building block to synthesize new polyesters with improved heat resistance. The materials have potential for applications requiring higher performance than conventional plastics and, following a different approach, it even showed promise when combined with recycled PET to create a new co-polyester.

- Nadir focused on transforming CO₂-derived polymers into filaments suitable for 3D printing. These filaments demonstrated good printability and flexibility, with one formulation incorporating hydroxyapatite for potential use in biomedical applications.

Supporting a Circular Economy Beyond Technology

In addition to the technological developments, CO₂SMOS also focused on the broader aspects needed to ensure the successful deployment of CO₂-derived materials. Market studies identified potential sectors for these bioproducts, while Life Cycle Assessments (LCA) evaluated their environmental benefits. Additionally, policy analysis examined regulatory pathways to integrate these innovations into EU frameworks, ensuring alignment with sustainability goals and facilitating their future industrial scale-up.

A Foundation for Future Innovation

While the technologies developed in CO₂SMOS are not yet market-ready, the project has demonstrated their technical feasibility and laid the groundwork for future scale-up.

“CO₂SMOS has helped close the loop on carbon use in bio-based industries. Thanks to the collaborative work of the consortium, we now have a set of validated processes that can move forward toward industrial deployment,” said Nicolás Martín Sánchez, the project coordinator from CARTIF Technology Center.

The consortium, which included leading research centres (CARTIF, CSIC, SINTEF, FUNDITEC, University of Amsterdam, RWTH Aachen, University of Twente, CERTH), industrial partners (Bio Base Europe Pilot Plant, Avantium, Novamont, Nadir, HERA Group), and organisations such as CO₂ Value Europe and RINA, will continue to collaborate beyond the project’s end to ensure knowledge transfer and impact across the European bioeconomy, as well as strengthening Europe’s position in the field of carbon capture and utilisation (CCU).

About the CO2SMOS Project

For more information on the CO₂SMOS project please visit https://co2smos.eu/.

Source

CO₂SMOS, press release, 2025-04-15.

Supplier

Avantium Technologies B.V.

Bio Base Europe Pilot Plant VZW

CARTIF

CERTH

CO2 Value Europe

CO2SMOS

FUNDITEC

Hera Group

Horizon 2020

Nadir

Novamont S.p.A.

Rheinisch-Westfälische Technische Hochschule Aachen (RWTH)

RINA Services

SINTEF

Spanish National Research Council (CSIC)

University of Amsterdam (UvA)

University of Twente (NL)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals