A BioSC workshop on the recycling of plastic waste was held in Aachen on 10th February. 45 scientists and entrepreneurs discussed different aspects of the topic ranging from depolymerisation to biotechnological and chemical conversion as well as the quantification of microplastics.

Plastic products are an integral part of modern society. Due to their wide range of applications and the high availability of inexpensive raw materials, petroleum-based polymers can be found in many everyday objects. However, since these polymers are very durable, plastic waste is causing a global pollution crisis. The development of production of plastic monomers and polymers from plastic waste using biotechnological and chemical methods offers the opportunity to replace fossil resources and close the carbon cycle for polymer production.

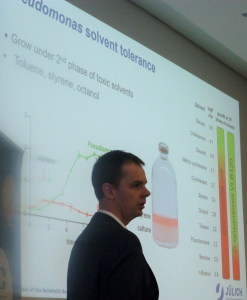

The workshop was opened by Lars Blank (RWTH Aachen), who uses plastic waste as substrate for the production of bioplastics in Pseudomonas putida. In this process, plastics are hydrolysed in the bacteria and polyhydroxyalkanoates (PHA) are produced from the released monomers. Bacterial growth was initially optimised for ethylene glycol and butanediol as carbon sources, which then serve as starting molecules for the production of PHA. Pseudomonads also play a central role in the work of Nick Wierckx (Forschungszentrum Jülich), who is optimising them for the production of phenol and other aromatic compounds. For the production of new plastics, phenol in particular plays a major role as a precursor molecule. The Pseudomonas strains used have to be optimised for high tolerance to phenol and other toxic organic solvents. Benedikt Weber (RWTH Aachen) presented his work on the tailor-made enzymatic degradation of polyurethane to hexamethylene diamine (HMDA). A particular challenge here is the extraction and purification of HMDA, which is necessary before HDMA can be used again for plastics production.

Tim Devlamynck presented the strategy of Indaver, a company which handles waste management and the recycling of materials and energy for entire companies. Indaver is thus able to make evaluations regarding the origin and type of plastic waste. The waste is used to produce styrene, which can then be used again for the production of plastic. Sonja Herres-Pawlis (RWTH Aachen) presented her work on the production of polylactide using metalloenzymes which, unlike the catalysts used to date, are non-toxic and enable PLA to be produced on an industrially competitive basis. Jürgen Klankermayer (RWTH Aachen) presented a process for recycling the mixture of PLA and PET. In this process, the starting materials can be hydrolysed to 99% by means of temperature variation and different catalysts.

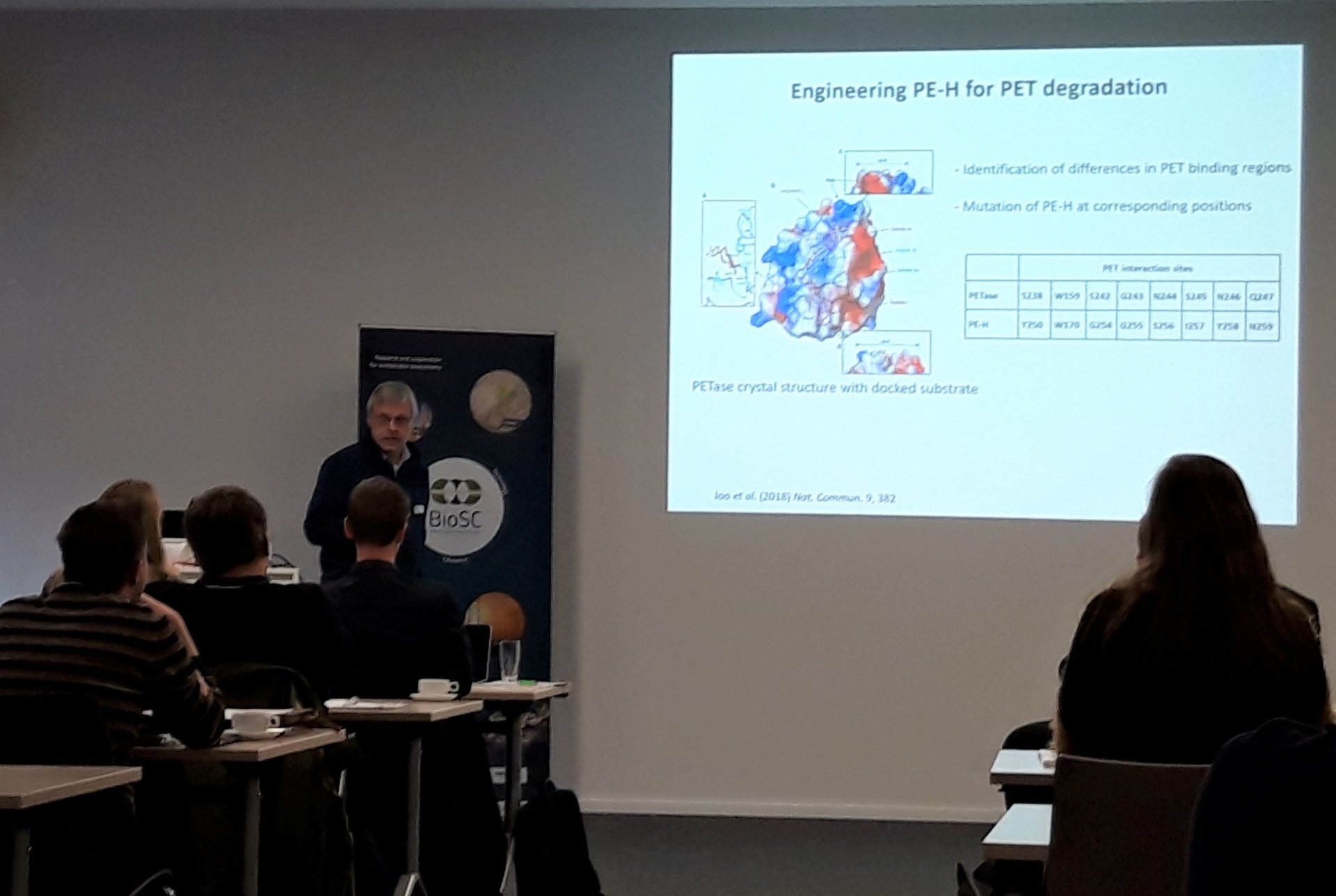

The workshop was concluded with the lectures of Ulrich Schwaneberg (RWTH Aachen/DWI Leibniz-Institut Aachen) and Karl-Erich Jaeger (HHU Düsseldorf). Ulrich Schwaneberg presented the anchor peptide technology developed in the BioSC FocusLab „greenRelease“ and its precursor projects. The anchor peptides have a broad range of applications and can be used for the targeted degradation and quantification of microplastics. In the last presentation of the day, Karl-Erich Jaeger presented his investigations into the degradation of PET by polyester hydrolases from marine microorganisms. These enzymes provide new possibilities for the recycling of plastic waste and could contribute to the reduction of plastic waste in marine systems.

Source

Forschungszentrum Jülich (BioSC), Newsletter, April 2020, 2020-04.

Supplier

DWI Leibniz-Institut für Interaktive Materialien

Forschungszentrum Jülich

Heinrich-Heine-Universität Düsseldorf

Rheinisch-Westfälische Technische Hochschule Aachen (RWTH)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals