As the world struggles with the mounting waste crisis, stringent recycling quotas and robust policy frameworks are driving the rapid development and adoption of advanced recycling technologies. These innovative processes, which include chemical, physical, and thermochemical methods, are fundamentally changing how industries and societies manage waste, offering sustainable solutions that extend beyond the limitations of traditional mechanical but also chemical recycling.

Advanced Recycling Technologies: An Overview

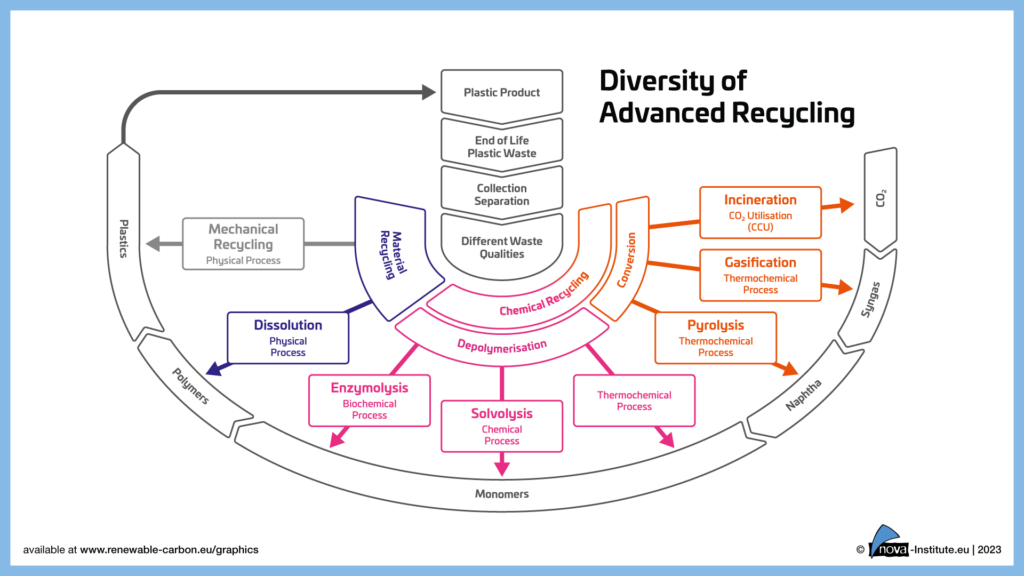

Advanced recycling reaches way beyond chemical recycling and encompasses a diverse array of processes designed to transform waste into high-quality recycled materials and chemicals. Key technologies in advanced recycling include:

- Gasification: Converts waste into syngas (a mixture of hydrogen and carbon monoxide) and CO2 through partial oxidation at high temperatures.

- Incineration with Carbon Capture and Utilisation (CCU): Combusts waste materials to generate energy, while capturing and utilising the resulting CO2 for industrial applications.

- Pyrolysis: A thermochemical process that decomposes waste at high temperatures in the absence of oxygen, converting it into liquid fuels, waxes, and other valuable chemicals.

- Thermal Depolymerisation: Uses heat and pressure to break down complex polymers into simpler hydrocarbons.

- Solvolysis: Utilises solvents to break down plastics into monomers and other chemical feedstocks.

- Dissolution: A physical recycling process where plastics are dissolved in a solvent and then recovered without breaking their chemical structure

- Enzymolysis: Employs enzymes to degrade plastics into their constituent monomers.

- Extrusion: This physical recycling process involves melting and reforming plastics into new products. It is often used as a preparatory step in other advanced recycling methods but may be used as standalone process

Waste Streams and Product Outputs

Advanced recycling technologies are effective at processing a variety of different waste streams. These include:

- Including polyethylene (PE), polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), and polyvinyl chloride (PVC). Common examples are plastic packaging and other mixed wastes.

- Waste rubber from tires and other sources, which can be converted into fuels and other secondary valuable chemicals such as carbon black.

- Synthetic fibres or mixtures of synthetic and natural/man-made fibres from clothing and other textile products, which can be separated from each other whereby the synthetic fibres are broken down into monomers and other chemicals.

By breaking down these materials into their chemical constituents, advanced recycling produces a range of high-value products such as:

- : Essential for manufacturing new plastic products with high purity and performance.

- A key feedstock for petrochemical industries.

- Includes solvents, lubricants, and other chemicals used in various industrial applications.

- Pyrolysis oil and syngas can be used as alternative fuels, contributing to energy recovery.

Industries and Sectors Benefiting from Advanced Recycling

The products of advanced recycling technologies support diverse industries and sectors, offering sustainable alternatives to traditional manufacturing processes. These sectors include energy production utilising pyrolysis oil and syngas as alternative fuels, petrochemical industries relying on recovered naphtha and secondary valuable chemicals (SVC), and plastics manufacturing for high-purity polymers and monomers. Additionally, advanced recycling supports chemical synthesis through the production of chemical feedstocks via solvolysis, and enzymolysis sectors focused on waste management benefit from solutions for challenging waste streams like heterogeneous and contaminated waste streams, multi-layered packaging and rubber from tires.

The integration of advanced recycling into these industries reduces reliance on virgin fossil resources, enhances resource efficiency, and contributes to sustainable development goals. Furthermore, logistics and transportation sectors benefit significantly from advanced recycling technologies by incorporating alternative fuels derived from pyrolysis oil and syngas, thereby reducing the use of and replacing fossil fuels and environmental impact throughout supply chains. Importantly, advanced recycling plays a pivotal role in renewable carbon strategies by keeping fossil and biobased carbon in the loop, minimising the extraction of new resources and promoting a circular economy approach to carbon management.

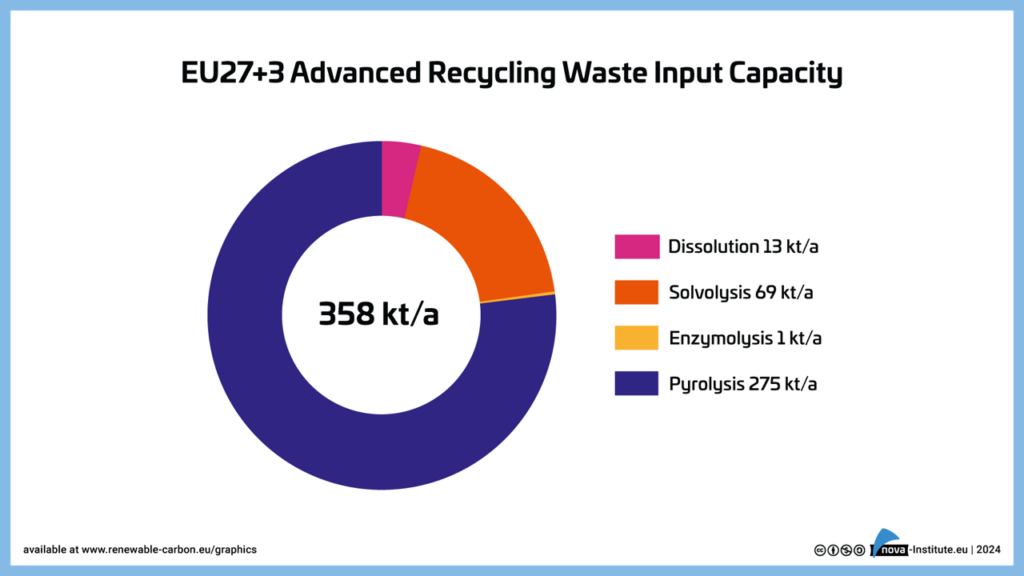

Current Capacities and Global Landscape

The growth in advanced recycling technologies has been substantial. According to nova-Institute’s 2024 report, over 340 advanced recycling plants are either planned, installed, or operational worldwide, providing a total input capacity of 1,477 kilotons per annum. Europe leads the global market, with more than 60 operational plants accounting for nearly a quarter of the worldwide input capacity. This positions Europe at the forefront of the advanced recycling sector, reflecting its strong commitment to sustainable waste management and circular economy principles.

Growth Trends and Future Projections

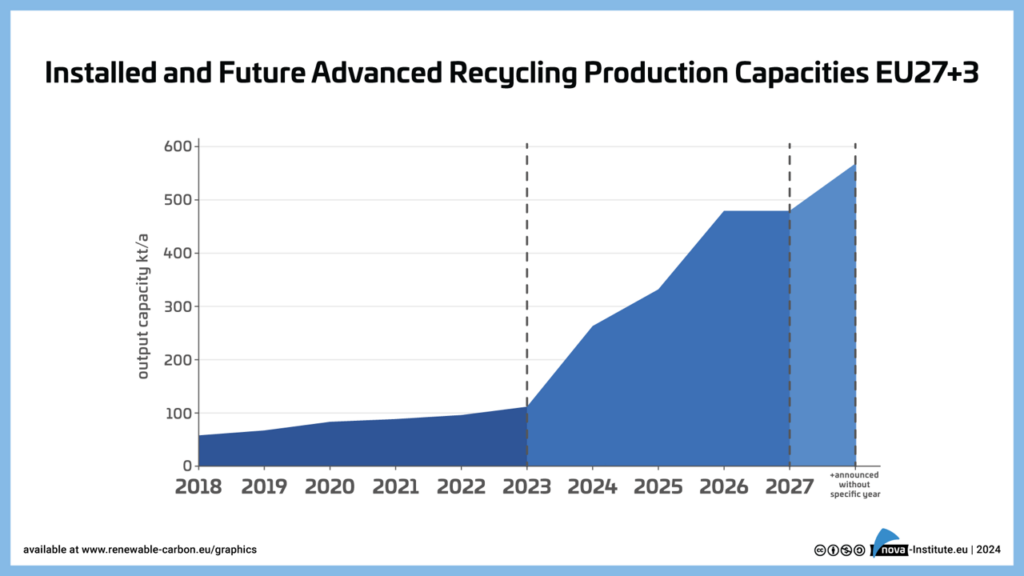

The advanced recycling market is poised for significant growth in the coming years. The report “Mapping of Advanced Plastic Waste Recycling Technologies and their Global Capacities” projects that by 2027, the input capacity in Europe will more than triple, while global capacity will double. This growth is driven by increasing investments, technological advancements, and supportive policy frameworks. The European Union’s stringent recycling quotas and policy requirements are key factors accelerating this expansion. For instance, the European Commission has set ambitious recycling targets to ensure that 55 % of all plastic packaging waste is recycled by 2030. These targets necessitate the development and scaling up of advanced recycling technologies to complement mechanical recycling and handle more complex waste streams.

The Role of Advanced Recycling in the Circular Economy

Advanced recycling plays a pivotal role in achieving a circular economy by providing sustainable solutions for waste management. It addresses the shortcomings of mechanical recycling, such as the inability to process contaminated or degraded materials and the limited recycling loops before material properties deteriorate. By converting waste into high-quality raw materials, advanced recycling reduces reliance on virgin fossil resources, and diverts waste from landfills and incineration.

Challenges and Opportunities

Despite its promising potential, advanced recycling faces several challenges. These include high operational costs, technological complexities, and the need for extensive infrastructure development. Moreover, regulatory uncertainties and the lack of standardised definitions and criteria for advanced recycling processes can hinder market growth. However, these challenges also present opportunities for innovation and collaboration among stakeholders, including technology providers, waste management companies, policymakers, and researchers.

Conclusion and Future Outlook

The future of advanced recycling looks promising, with continuous advancements and increasing adoption expected to drive significant growth. As the market expands, it will be crucial to address existing challenges through technological innovation, supportive policies, and collaborative efforts. By doing so, advanced recycling can play a critical role in achieving global sustainability goals and transitioning towards a circular economy.

Additionally, on 20-21 November 2024, nova-Institute will host the Advanced Recycling Conference 2024 in Cologne, Germany and online. The event offers a platform for industry stakeholders and researchers to discuss the latest developments and innovations in advanced recycling and policy. Early birds can secure a 20 % discount on registration until July 16th, 2024, at: https://advanced-recycling.eu/registration/

By embracing advanced recycling technologies, significant strides can be made towards sustainable waste management and a greener future. Find more information on the Advanced Recycling Conference 2024 here.

References

European Commission, 2020. A European strategy for plastics in a circular economy. Available at: https://ec.europa.eu/environment/circular-economy/pdf/plastics-strategy.pdf (Accessed: 11 July 2024).

nova-Institute (Krause, L., Özgen, A., Kern, J., Das, S., Carus, M. and Raschka, A.) 2024: Mapping of Advanced Plastic Waste Recycling Technologies and their Global Capacities. nova-Institut GmbH (Ed.), Hürth, Germany, 2024-02. https://doi.org/10.52548/WQHT8696

Author

Lars Krause, Senior Scientist (nova-Institut)

Source

nova-Institute, original text, 2024-07-15.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals