Showing 101–120 of 200

-

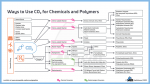

Ways to Use CO₂ for Chemicals and Polymers – Graphic (PNG)

Markets & Economy, Technology

1 Page

1091 Downloads

1091 Downloads

2023-04

FREE

Plus 19% MwSt.1091

Downloads -

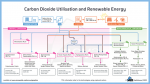

Carbon Dioxide Utilisation and Renewable Energy − Graphic (PNG)

Markets & Economy, Technology

1 Page

1523 Downloads

1523 Downloads

2023-04

FREE

1523

Downloads -

555 Downloads

2023-02

FREE

555

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

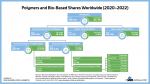

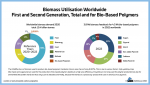

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

189 Downloads

2023-02

FREE

189

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

Shares of the produced bio-based polymers in different market sements in 2022 (PNG)

Markets & Economy

1 Page

312 Downloads

312 Downloads

2023-02

FREE

312

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

479 Downloads

2023-02

FREE

479

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

384 Downloads

2023-02

FREE

384

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

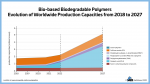

Bio-based biodegradable polymers – Evolution of worldwide production capacities 2018 to 2027 (PNG)

Markets & Economy

1 Page

516 Downloads

516 Downloads

2023-02

FREE

516

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

Bio-based non-biod. polymers – Evolution worldwide production capacities 2018-27 (PNG)

Markets & Economy

1 Page

211 Downloads

211 Downloads

2023-02

FREE

211

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

Bio-based polymers – Evolution of worldwide production capacities from 2018 to 2027 (PNG)

Markets & Economy

1 Page

516 Downloads

516 Downloads

2023-02

FREE

516

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

387 Downloads

2023-02

FREE

387

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

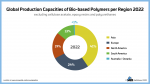

Global Production Capacities of Bio-based Polymers per region 2022 (PNG)

Markets & Economy

1 Page

275 Downloads

275 Downloads

2023-02

FREE

275

DownloadsReport on the global bio-based polymer market 2022 – A deep and comprehensive insight into this dynamically growing market

The year 2022 was a promising year for bio-based polymers: Bio-based epoxy resin production is on the rise, PTT regained attractiveness after several years of constant capacities and PE and PP made from bio-based naphtha are being further established with growing volumes. Increased capacities for PLA are ongoing, after being sold out in 2019. Current and future expansions for bio-based polyamides as well as PHAs are on the horizon. And also, bio-based PET is getting back in the game.

DOI No.: https://doi.org/10.52548/CMZD8323

-

Overall turnover and employment of the bioeconomy and its bio-based industries in the EU-27 in 2019

Markets & Economy

1 Page

126 Downloads

126 Downloads

2022-10

FREE

126

DownloadsThe new nova-Institute’s market report commissioned by the Bio-based Industries Consortium (BIC) shows macroeconomic effects of the European Bioeconomy in the period from 2008 to 2019. Using data from Eurostat and, where required, nova-Institute’s estimated bio-based shares, turnover and employment numbers of the bioeconomic sectors have been calculated. Even though the latest numbers no longer include the UK, the EU’s bioeconomy turnover remained stable, which has resulted in an increase of around 25% since 2008.

This graphic shows the overall turnover and employment of the bioeconomy and its bio-based industries in the EU-27 in 2019.

-

Environmental impacts of 250 ml monolayer and PET/PEF multilayer bottles vs. their fossil counterparts (PNG)

Sustainability & Health, Technology

1 Page

153 Downloads

153 Downloads

2022-08

FREE

Free Shipping153

DownloadsThis figure shows the climate change and resource use impact of PEF bottles versus PET bottles. nova-Institute’s peer-reviewed LCA evaluated 16 different impact categories covering all relevant life cycle stages from cradle-to-grave. The comparative analysis showed that PEF bottles would result in significant reductions in greenhouse gas emissions (-33%) compared to reference PET bottles. PEF would also lead to 45 % lower finite resource consumption of fossil fuels and reduce the pressure on abiotic resources (minerals and metals) by 47% due to the mechanical properties of PEF enabling light-weighting.

However, PET bottles would outperform PEF-bottles in other impact categories mostly arising from the current feedstock supply. Overall, this represents a benefit because climate change and resource use are among the most relevant environmental impact categories in the current political agenda as they are driving the transition from fossil to renewable carbon. Included in the nova-Institute’s LCA were next to 100% PEF bottles also 250 ml PET/PEF multilayer bottles with 10% of PEF compared to reference PET/PA bottles with a typical 7% of PA. The analysis of the multilayer bottles showed that significant reductions of around 37% in GHG emissions could be achieved by replacing the PA layer with PEF, mainly attributed to the recyclability of the PET/PEF system over the non-recyclability of the PA containing system. This replacement would also contribute to a significant reduction of finite resources demand (36% and 52% for fossils and minerals and metals respectively).

-

291 Downloads

2022-08

FREE

Free Shipping291

DownloadsAvantium has developed a technology to convert plant-based sugars into FDCA (furandicarboxylic acid), the building block of PEF (polyethylene furanoate): a plant-based, fully recyclable polymer with superior performance. FDCA is polymerised with plant-based mono-ethylene glycol (MEG) to make a 100% plant-based PEF polymer. In December 2021, Avantium has taken a positive investment decision concerning the construction of the world’s first FDCA Flagship Plant in Delfzijl (The Netherlands), with construction planned to be completed by the end of 2023 and the aim to be operational in 2024. This will be the world’s first commercial FDCA facility and will have a targeted production capacity of 5,000 tonnes per annum. FDCA is the key building block for the 100% plant-based, recyclable polymer PEF.

-

153 Downloads

2022-08

FREE

Free Shipping153

DownloadsPEF has enhanced barrier, mechanical and thermal properties compared to today’s widely used

petroleum-based polymers. The barrier properties of PEF, which are ~10x better for O2, ~15x better

for CO2 and ~2.5x better for water than PET, represent a revolutionary opportunity compared with traditional packaging solutions regarding performance, price, and sustainability when produced at scale. The improved barrier properties lead to a longer shelf life of packaged products. PEF also offers higher mechanical strength, which means that thinner PEF packaging can be produced and fewer resources are required.

In terms of thermal properties, PEF has superior ability to withstand heat and can be processed at lower temperatures. PEF has enhanced mechanical stiffness and allows for increasing shaping possibilities. -

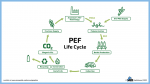

Life cycle stages of monolayer PEF bottles (PNG)

Sustainability & Health, Technology

1 Page

134 Downloads

134 Downloads

2022-08

FREE

Free Shipping134

DownloadsThis figure shows the relevant life cycle stages of monolayer PEF bottles from cradle-to-grave: from the biomass cultivation (wheat for fructose and sugarcane for bio-MEG feedstocks supply) to the production of PEF-based bottles including their end-of-life options (recycling and incineration).

It is foreseen that the commercialisation of PEF-based products will initially take place in the Netherlands, Belgium, and Germany. In these countries, the rates for average PET bottle waste collection and recycling are relatively high and landfilling is no longer practiced in these countries. -

887 Downloads

2022-06

FREE

Free Shipping887

DownloadsLife of a polymer from the production to its disposal (e.g. landfill) indicated with black arrows including various recycling and recovery routes indicated in different coloured arrows.

-

Identified Advanced Recycling technology providers worldwide and maximum capacity (PNG)

Technology

1 Page

340 Downloads

340 Downloads

2022-06

FREE

Free Shipping340

DownloadsOverview about identified advanced recycling technology providers (blue bars) and maximum capacity (orange lines) depending on the technology.

-

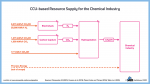

CCU-based Resource Supply for the Chemical Industry (PNG)

Sustainability & Health, Technology

1 Page

251 Downloads

251 Downloads

2022-05

FREE

251

DownloadsIt is a plausible scenario to assign methanol (CH₃OH) a central role in supplying the chemical industry of the future. Already today, methanol plays an important role in the chemical industry, being one of the most established commodities.

CCU-based process route for production of methanol includes production of hydrogen via electrolysis, CO₂ capture from the atmosphere or from industrial point sources, and the hydrogenation reaction. Electricity demand for these processes is represented by red arrows. Above the arrow, the specific energy demand is stated, below, the contribution of the process to the total electricity demand of 1 t of methanol is stated. Purification and compression of hydrogen are neglected. For CO₂ hydrogenation, a complete reaction is assumed.