From June 10-12, the Renewable Materials Conference (RMC) brought together chemical supply chain stakeholders in Siegburg, Germany, working to devise materials and technologies for a future beyond fossil fuels.

“What is most urgently needed is a sustainable, integrated and coherent strategy for energy, climate and the circular economy, together with a coherent, science- and evidence-based policy framework at global, regional and national levels that takes into account regional and national differences in equity and intra-intergenerational justice.” Food for thought with which Reinhold Lang from Johannes Kepler University in Linz introduced the breadth of the ongoing challenge during the RMC.

New supply models and investments needed

Painting a worrying picture for the chemical and petrochemical world, however, has been Hans Rovers of New Normal Consulting of Switzerland. According to Rovers, the European petrochemical industry is facing disruptive change. Margins are falling in Europe, while costs are among the highest in the world for raw materials and energy. At the same time, European volumes are declining, imports are steadily rising and local demand is collapsing, as materials and products are increasingly available at lower costs elsewhere. In Rovers’ analysis the future does not look bright, due to the huge global overcapacity in the industry brought about by competition from the United States, the Middle East and China as well as to falling prices.

Adding to concerns is the need for massive investment, aimed at ensuring access to non-fossil carbon and hydrogen sources and developing technologies and infrastructure to defossilize European processes. Europe has, in addition, one of the most stringent regulations with respect to CO₂ emissions.

The situation in the EU, however, is set to change significantly. On the one hand, this is due to the massive information work done by players such as CO Value Europe (CVE) and the Renewable Carbon Initiative (RCI), which have highlighted the importance of CCU as a key technology. On the other hand, the European Commission (EC) has begun to recognize that CCU will be needed for defossilization of fuels, chemicals and materials, and for sustainable carbon cycles.

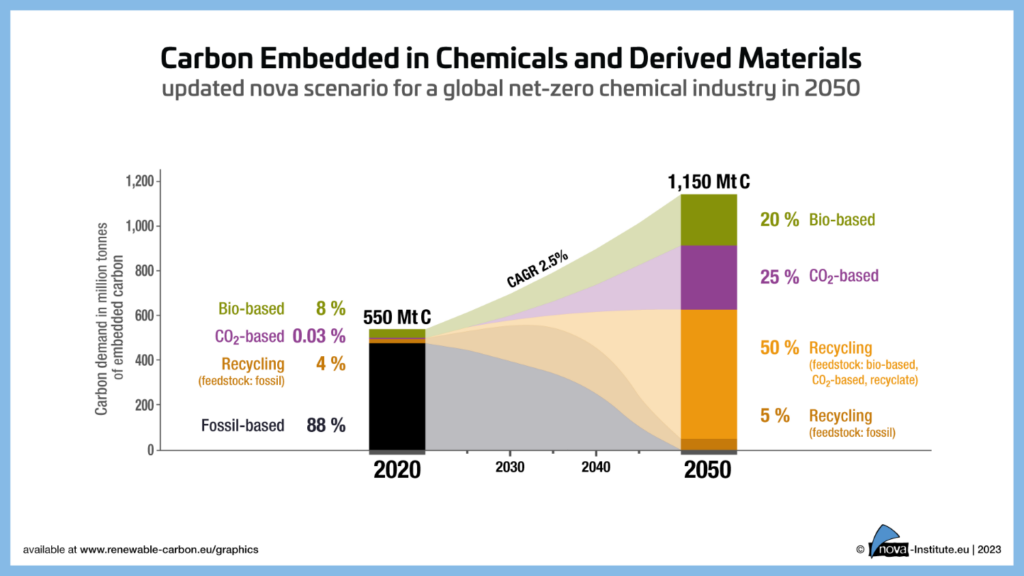

Despite the efforts of many large and small companies, the reality is that our societies are still largely dependent on fossil fuels. In an era where volatility, uncertainty, complexity and ambiguity (the so-called VUCA) prevail, Ivana Krkljus, Global Strategic Bioeconomy Advocacy, Renewable and Recycled Carbon Policy at BASF, outlined the need to develop something different that goes beyond carbon dependence.

Krkljus’s statement was a call to all stakeholders in the supply chain also because, as she said, “sustainability in marketing is dead, we need to move to sustainable marketing. Claims need to be carefully validated so they are not just empty green statements.”

Technologies, new materials and ongoing research projects

To change this scenario, there are many critical issues to be addressed and improved, from fine chemistry products, i.e., pharmaceuticals, detergents, sealants and functional applications, to the new generation of adhesive materials and coatings. New bio-based materials are being researched as well as innovative mechanical, physical and chemical recycling technologies for different types of plastics.

Over 500 conference participants presented the state of the art in the chemical sector, discussing sustainable carbon cycles, renewable refineries and recycling of chemicals, as well as new process and production technologies for renewable chemicals, polymers and plastics, with the Northern European industry, German and Dutch in particular, taking center stage. For the success of new products such as resins, additives, renewable functional fillers, the question of biodegradability and the possibility of domestic or industrial composting remains crucial.

Wood and sugar, sucrose in particular, are among the bio-based materials that many companies in the industry, such as UPM and Cosun Beet Company, are focusing on in order to at least partially replace fossil-derived components. If Dow is investing in devising new surfactants to reduce the carbon footprint of its household cleaning products, the U.S.-based International Flavors & Fragrances is researching and designing new enzymatic biomaterials to enhance its flavors and fragrances, which can be found in many foods and beverages normally on the market. In Portugal, on the other hand, CeNTI, Center for Nanotechnology and Smart Materials, is looking at bioeconomy and marine waste to bring sustainable fashion solutions to life.

The many projects presented at the RCI show the vibrancy of the ongoing initiatives underway, but also the difficulty of bringing products to market and the awareness of the urgency of the current situation.

As René Bethmann of VAUDE Sport, a German outdoor company currently involved in several projects and with several partners to recycle polyester, said, “a material takes 20 to 30 years to spread and consolidate in the market, but unfortunately we no longer have that time available.”

Recycling is still crucial

Mechanical, physical and chemical recycling technologies play an essential role in achieving the goals of the Green Deal. If, as pointed out by many participants and speakers at the Renewable Materials Conference, it is not possible to do without recycling − a process that seems easier at the moment than a complete redesign of different products − the road is still long.

As Matthias Wilhelm, head of plastics recycling and research and development at Lober, says, “there is a long way to go. It’s necessary to get to a vertical integration of all parties, consumers, brand owners, recyclers, legislators and policy makers. The success of recycling cannot be a task left to individuals; collaboration between different actors is crucial.”

At the same time, it remains necessary to address the issue of material consumption, which continues to grow. Recycling plastics and improving technologies can curb some of the demands, but it is always crucial to focus on zero-level R, i.e., “Refuse“: refusing to buy new goods is in fact the first step to not generating waste.

The Renewable Carbon Initiative’s Position Paper on Physical and Chemical Recycling

The Renewable Carbon Initiative (RCI), founded by Nova Institute with the goal of completely replacing fossil-derived carbon with renewable carbon sources, including biomass, CO₂ and recycling, has presented a Position Paper on physical and chemical recycling. The paper, presented by Micheal Carus during the second day of the Renewable Materials Conference, lists the demands and views of a global network of more than 60 companies including Nestle, UPM and Covestro.

The paper includes request to mandatory recycled content for all polymers/plastics in all applications – packaging, automotive, textiles and all other sectors. The recycled content should include all types of mechanical, physical and chemical recycling, as well as the request for the general acceptance, recognition and clarified rules for chemical and physical recycling technologies in the calculation of recycling rates for all sectors, building on established tracing and certification systems.

RCI also supports the political agreement between EU institutions to introduce minimum recycling quotas also for “contact sensitive packaging” of between 10% and 30%, depending on the polymer and application.

The Renewable Material of the Year innovation award

Denmark’s Again, Sweden’s Reselo and Germany’s VAUDE Sport were honored as the Renewable Material of the Year innovation awards organized by the Nova Institute and sponsored by Covestro.

Prior to the event, in fact, a jury composed of representatives from the Nova Institute, the Advisory Board and conference sponsors selected the six best innovations from the 38 nominations submitted. At the end of the second day of the RMC, each of the six selected companies presented their innovation in a 10-minute pitch. After the presentations, the three winners were selected by conference attendees and announced shortly thereafter.

Author

Antonella Ilaria Totaro

Source

Supplier

Aduro Biopolymers

Again

amynova polymers

BASF Corporation (US)

CeNTI Centre for Nanotechnologie and Smart Materials (PT)

Cosun Beet Company

Covestro AG

DG GROW - European Cluster Collaboration Platform

eChemicles (HU)

European Commission

European Union

Lober Entsorgung

Normal Consulting (CH)

nova-Institut GmbH

Renewable Carbon Initiative (RCI)

reselo

UPM Corporation

VAUDE

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals