© Christian Kleinmann

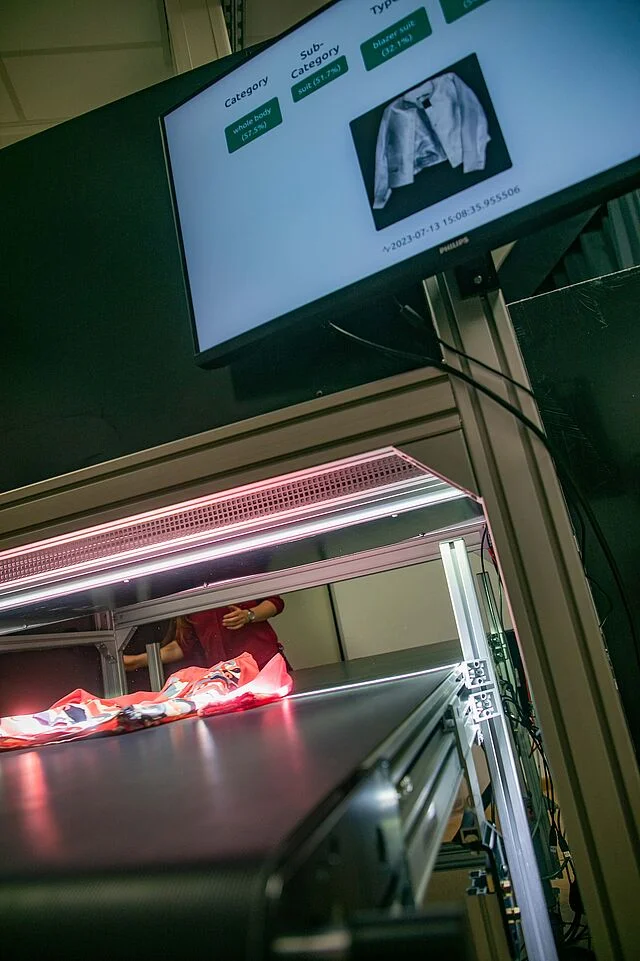

The conveyor belt accelerates rapidly. A broad strip of light scans a white blouse before it falls into a basket. A yellow sweater rolls up and is scanned, then a pair of blue jeans and a red coat. Photos of the scanned garments appear on a screen along with information about the product type, color, and target group. The black textile scanner developed by a team of researchers from TU Berlin, FU Berlin, and circular.fashion has the potential to revolutionize the sorting of used garments, thus making the second-hand clothes sector much more attractive. A welcome and much-needed development, given the impact of clothing on the climate. The trend for fast fashion means that the fashion industry is today responsible for an estimated 8% of global carbon emissions.

“Up until now, used clothing has been sorted by hand. This is a time-consuming process, as each item has to be handled two to three times before its product type and condition can be identified,” says Karsten Pufahl from TU Berlin’s Department of Nonlinear Optics, who is heading research within the project.

If the yellow sweater is in good condition, is a high-quality brand, or is in line with current fashion trends, it is suitable for the domestic or Western European second-hand market. Such items, as Pufahl explains, are known in the industry as cream wear, and are where the most money is to be made. The demand for second-hand clothing is increasing, with flea markets, online selling platforms, and even major fashion chains now offering pre-owned products. Items which can no longer be worn are processed into cloths, painter’s fleece, or car seat filling. The remaining used textiles in Germany and elsewhere in Europe, often including unwearable clothing, are mainly exported to Africa. However, this is set to change in the near future. The European Union wants to put a stop to the export of clothing that is no longer usable to third countries, where it generates waste. This will require an increase in sorting in Europe in the future, but there are currently too few people trained to do this.

AI-backed image analysis

This is where project CRTX comes in. The black scanner is equipped with AI-backed image analysis capable of recognizing the product type in a matter of seconds, as well as whether an item of clothing is suitable for the second-hand market or recycling. Karsten Pufahl and his team also monitor the current fashion market to identify trends, train the AI, and thus help second-hand retailers to respond directly to customers’ wishes. This will help ensure that more clothing gets a second life. In the future, the scanner will be able to recognize further product characteristics to achieve optimum recycling. This advanced sorting is being worked on in a follow-up project, which has been running since the middle of the year and is funded by the Federal Ministry for Economic Affairs and Climate Action with around 2.3 million euros, 1.3 million euros of which is earmarked for TU Berlin. The scanner is currently housed at a large recycling company in Hamburg, where the AI is to learn to recognize different quality levels based on thousands of items of clothing. There is already plenty of interest in the end product, and a patent application has been submitted.

Fiber-to-fiber recycling

In the second part of the project, the team focused on fiber-to-fiber recycling, which enables yarn of the same quality to be recovered from used textiles and then processed into a new textile product. This high-quality recycling method is still seldom used because fiber identification using near-infrared spectroscopy is too imprecise. With a few textiles, such as white bed sheets or jeans, it is possible to say with some certainty what material they are made of and what hazardous substances they contain, so that new textiles can be made from them. This is more difficult with other clothing, which often consists of a mixture of different fibers. As part of the CRTX project, Pufahl and his colleagues have developed a process that can precisely identify each type of textile using Raman spectroscopy. Raman spectroscopy, which is frequently used in laboratory analysis, previously had a problem with fluorescence. The reason for this is that organic materials, of which textiles are also made, fluoresce, and thus interfere with the measurement. Thanks to the work of the research team in developing the process, this problem no longer exists.

Detecting hazardous substances

Certain hazardous substances in textiles can now also be measured.

“This is actually rather more tricky than it sounds, as it is difficult to obtain the hazardous substances and find the contaminated clothing that is needed to train the software to recognize them,” says Karsten Pufahl.

In addition, it is still not clear precisely which fiber-to-fiber recycling process will prevail. Currently, there is a huge gap between the sorting requirements of recyclers and what is technically feasible in terms of material recognition. According to Pufahl, more openness and further exchange is needed on both sides to find out exactly how this gap can be closed. This would be an important step towards recovering fibers of the same quality and free of hazardous substances, and using them to make new, pollutant-free textile products in line with the circular economy.

Contact

Dr. Karsten Pufahl

E-Mail: info@fashionsort.ai

Source

Technical University of Berlin (TU Berlin), press release, 2024-01-08.

Supplier

Bundesministerium für Bildung und Forschung (BMBF)

Technische Universität Berlin

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals