Two worlds, two partners, one goal: FUCHS and Fraunhofer UMSICHT aim to achieve great things with the tiny Cupriavidus necator. The bacterium can perform a real wonder: it consumes waste and turns it into bioplastic. Let’s take a look at a highly innovative project, in which application expertise from Mannheim and research know-how from Oberhausen complement each other perfectly.

It may only be one micrometer in size, but it has a big appetite: the bacterium Cupriavidus necator. The tiny life form loves carbon compounds and devours anything that contains them: diapers, food waste, waste paper, sewage sludge… and the best part is, it turns them into bioplastic as a metabolic product. Biodegradable polyhydroxyalkanoates (PHAs), to be precise. These PHAs are the focus of the PHAtiCuS project, which unites the skills of Fraunhofer UMSICHT, FUCHS LUBRICANTS GERMANY, UnaveraChemLab, and Fritzmeier Environmental Technology. These biopolymers have tremendously great potential.

THE BEGINNING

Ambulances, wind turbines, trains – all these machines need lubricants and they, in turn, usually need thickeners. The thickeners currently consist of metal soaps or inorganic fillers, plastics and polyureas.

THE PROBLEM

If such products get into the environment during operation of the lubricated machines and systems – as a result of design or leaks – this endangers the soil and groundwater.

THE SOLUTION

Rapidly biodegradable lubricants that require alternative thickeners. Such thickeners should preferably be developed on the basis of natural materials – for example PHAs.

What can the industry expect from the biopolymers? And which challenges do research and application face? Dr. Inna Bretz from Fraunhofer UMSICHT and Rolf Luther, project manager at FUCHS, report.

Waste-eating bacteria that produce usable plastic – that sounds like a dream come true for any environmentalist!?

Dr. Inna Bretz: It certainly does. The use of waste materials in chemistry is always present, for example in large chemical parks. However, biotechnological processing of waste materials doesn’t work with all “trash”, as any impurities can significantly impair or hamper the process. The adjective “usable” is important. It’s possible to produce polymers, and developing synthetics with useful properties from them is exactly what we are researching at Fraunhofer UMSICHT. Yet the primary goal must be to avoid or reduce the amount of waste through a sustainable circular economy and practical system solutions.

Please explain briefly what exactly Cupriavidus necator can do.

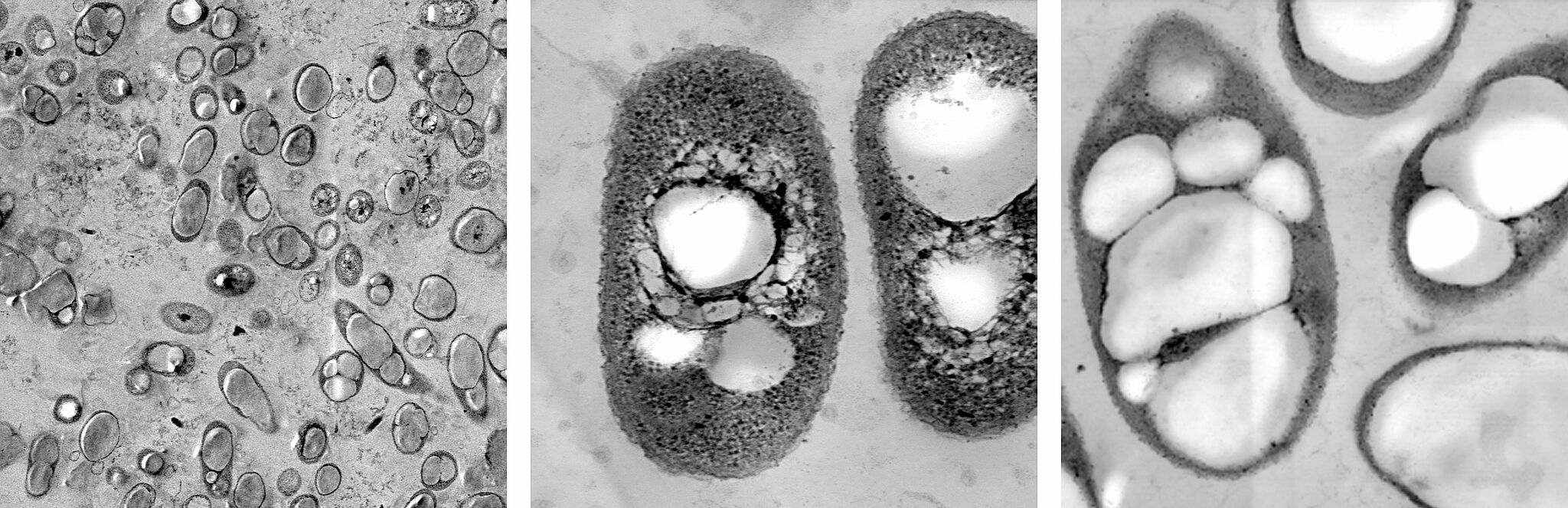

IB: Microorganisms use carbon compounds like sugar, short-chain acids, alcohols, oils, and greases as “food”. The polyhydroxyalkanoates or PHAs formed in the cells are part of the energy metabolism of certain genuses of bacteria, including Cupriavidus necator. They are stores for times when food sources are present, but no nutrients like hydrogen salts or phosphorous salts are available.

And we can use the PHAs as the basis for developing rapidly biodegradable thickeners.

700.000 tons of lubricants were supplied in Germany in 2020.

How did scientists come across this bacterium – and how can it benefit lubricant research?

IB: Cupriavidus necator was isolated from soil samples. With sugar as a substrate, it can accumulate up to 90 percent of its dry cell mass in PHAs and is thus ideally suited for their production. However, pure PHA types are not compatible with conventional base oil types and must therefore be chemically modified. In this way, mechanical and thermal properties and also those such as solubility can be adapted. Through the targeted modification of PHAs, we have succeeded in developing a thickening agent for lubricants.

Fraunhofer UMSICHT and FUCHS are working together on the PHAtiCuS project, which aims to develop marketable lubricants on a PHA basis. What exactly is FUCHS’s task and what does Fraunhofer UMSICHT do?

IB: We don’t just develop PHA-based polymers that can be used as thickeners in lubricants. We also test the selected thickeners and lubricant formulations for biodegradability and perform lifecycle analyses.

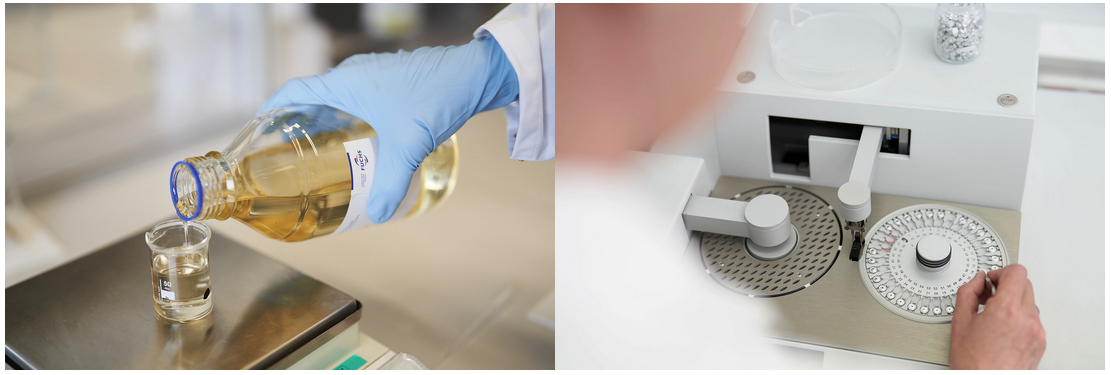

Rolf Luther: At FUCHS, we build on the samples from Fraunhofer UMSICHT: We look at important properties of the new polymers, such as their solubility in base fluids like hydrocarbons, esters, polyglycols, and others. This is followed by rheological investigations in which the thickening properties of the PHAs are qualified. Finally, suitable PHA candidates are integrated into fully formulated lubricating greases – and tested in the laboratory and test bay in an application-oriented manner.

60 percent or more is what the biological decomposition rate within 60 days should be for a lubricant for it to be classified as “rapidly biodegradable”.

How do these lubricating greases perform? Do they also hold up to extreme conditions, such as in the cement industry or in power transmission engineering?

RL: This is indeed a crucial step in development: it would be foolhardy to assume that a new raw material is suitable for all applications at a marketable cost. So after a basic characterization of the material, the question is for which purposes it seems suitable from a technical, ecological, and economic point of view. This process is still ongoing – but we have realized the first concrete steps.

| Cupriavidus necator | |

|---|---|

| Family | Burkholderiaceae |

| Provenance | University Park, Pennsylvania |

| Residence | in soil |

| Size | 0.9 to 1.3 micrometers |

| Hobby | Eating |

| Favorite food | Sugar, short-chain acids, alcohols, oils, and greases |

| Special talent | Creates biopolymers like PHAs as storage materials when “food” but no nutrients like hydrogen salts or phosphorous salts are available. |

Does it make any difference in terms of the properties of the PHA whether the bacterium eats diapers or old newspapers?

IB: No, what’s decisive for the production of the PHAs is the molecular size of the foodstuffs. If the cellulose found in newspapers or cloth diapers is broken down into glucose, the source isn’t important. There should not be any toxic impurities in the initial material, however.

What are the primary applications for the PHAs?

IB: PHAs are thermoplastic, biodegradable in almost all environments, and form no toxic products during decomposition. They can be processed on conventional systems and in 3D-printing. Depending on the property profile of the PHAs, products such as consumer goods, packaging, films, or fibers can be produced. Because of their biocompatibility with living tissues, PHAs are also used in the field of medicine and pharmaceuticals in applications such as implants or suture material.

RL: We have two product groups in mind: lubricating greases, where PHAs are used as thickeners, and solid film lubricants, in which PHAs serve as binders. But as I’ve said, determining which applications can be realized is the task of a longer-term development process.

How great is the demand for bio-based, biodegradable lubricants like these?

RL: The market is still relatively small. Although there are various environmental labels that can be used to document the sustainability of a lubricant, there is no obligation to use them, such as in sensitive environments. And – this needs to be said too – bio-lubricants are almost exclusively more expensive than conventional ones produced from mineral oil.

Cupriavidus necator is able to accumulate 90 percent of its dry cell mass as PHAs in the presence of sugar as a substrate. The bacterium is thus ideally suited for their production.

What are the challenges you see for PHA-based lubricants?

RL: In the phase of a possible market launch in particular, it is not just the environmental or sustainability statement that matters. It is also about the technical added value of the product. If this can be proven, a higher price can be justified to the customer – for example, because the lubricant has a particular friction-reducing effect. We are therefore currently working on identifying applications for which the new raw material is particularly suitable.

The raw materials are responsible for around 90 percent of the carbon footprint of the finished lubricant. FUCHS would like to offer original carbon-neutral products in the long term. What does the PHAtiCuS project mean for this goal?

RL: The more sustainable a raw material is, the better it is for our carbon objectives. However, please don’t forget the far greater contribution made to carbon emissions in the usage phase of a lubricant in a machine. That’s why it is so essential for us to be able to offer the lowest-friction, most efficient lubricant in every individual application. It would be fatal to select lubricants solely on the basis of their carbon footprint in the future. We need to compare this with the emissions-saving potential in the application and then make a selection looking at the entire value chain.

Valuable knowledge for the future

The Fraunhofer Gesellschaft is one of the world’s leading organizations for application-oriented research. It employs more than 30,000 people, predominantly with a background in natural sciences or engineering, in 76 institutes and research facilities. One of them is Fraunhofer UMSICHT, the Fraunhofer Institute for Environmental, Safety and Energy Technology. This is where 577 employees develop innovative, industrially implementable technologies, products, and services for the circular economy. The focus is on balancing economically successful, socially equitable, and environmentally-friendly developments.

Source

Fuchs Lubricants Germany, press release, 2023-01-10.

Supplier

Bundesministerium für Bildung und Forschung (BMBF)

Fraunhofer-Institut für Umwelt-, Sicherheits- und Energietechnik (UMSICHT)

Fritzmeier Umwelttechnik

Fuchs Schmierstoffe GmbH

Graz University of Technology

Unavera ChemLab GmbH

University of Graz

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals