Deutsche Version: www.bio-based.eu/news/mikroplastik-der-umwelt-quellen-folgen-und-losungen

Scientific studies have shown that plastics make a huge contribution to the ‘littering’ of the seas. In marine protection, plastic particles with a diameter of less than 5mm are referred to as microplastics. These can be fragments created by the breaking up of larger pieces of plastic such as packaging, or as fibres are washed out of textiles. They can also be primary plastic particles, produced in microscopic sizes. These include granulates used in cosmetics, washing powders, cleaning agents and in other applications. The following article describes the source of microplastics, the effects they have on the ecosystem and on people, and discusses potential solutions. For the first time, on July 1st 2014, a conference will be dedicated to this topic in Germany.

Waste in the oceans and inland waters is dominated by plastics (Barnes et al. 2009). The United Nations Environment Programme (UNEP) assumes coverage of up to 18,000 pieces of plastic for every square kilometre of ocean (UNEP 2006). It can take centuries for plastic to be broken down in the oceans by physical, chemical, and biological decomposition processes (UBA 2010). Along with larger waste items such as plastic bottles or bags, steadily increasing amounts of plastic microparticles – commonly known as ‘microplastics’ – are being observed in ocean gyres, sediments, and on beaches, as well as being found in marine organisms.

The term ‘microplastics’, however, is not used consistently. In the cosmetics industry, it is used to describe plastic granulates that in many cases are much smaller than 1mm in diameter. In marine protection, in contrast, plastic particles with a diameter of less than 5mm are considered microplastics (Arthur et al. 2009). On the other hand, Browne et al. (2011) use the term for plastic particles with a diameter of less than 1mm. Neither source gives a lower value for the diameter of particles, meaning that the term ‘microplastics’ also includes significantly smaller particles (Leslie et al. 2011). ‘Microplastics’ can therefore be considered an umbrella term for various plastic particles determined solely on the basis of size (cf. Table 1).

Table 1: Classification of marine plastic debris on the basis of size (Source: own representation based on JRC 2013, STAP 2011)

| Plastic waste in the oceans | Diameter of marine plastic debris | Typical dimensions of marine life-form | Typical dimensions of plastics in industry |

| Macroplastic | > 25 mm | Fish, shellfish, mussels etc. | |

| Mesoplastic | 5 – 25 mm | Production of plastic granulates/pellets | |

| Large microplastic particle | 1 – 5 mm | ||

| Small microplastic particle | < 1mm | Plankton | Applications of microplastics in the cosmetics industry |

In accordance with this definition, in the text that follows, all plastic particles with a diameter smaller than 5mm are termed ‘microplastics’.

Sources of microplastics

In February 2014 Bund für Umwelt und Naturschutz Deutschland e.V. (BUND) published a list of cosmetics containing micro particles from plastics. The most commonly used polymers in cosmetics are polyethylene (PE), polypropylene (PP) and polyamide (PA). Ethylene vinyleacetate-copolymers (EVA), polyuretane (PUR), and copolymers from acrylnitrile with metacrylate or other acrylates are also in use (Leslie et al. 2012). The Dutch “Instituut voor milieuvraagstukken” (IVM) found also micro particles from polyethylene terephthalate (PET) and polymethyl methacrylate (PMMA).

Manufacturers add synthetic polymers to cosmetics for a number of reasons: some help to distribute the substance; others help to develop to form a film on skin, hair or nails. Polyethylene for example possesses film-forming and viscosity-regulating properties according to the International Nomenclature of Cosmetic Ingredients (INCI). Furthermore uses the cosmetics industry micro particles from microplastics as abrasives, they are designed to remove impurities from the skin or to clean teeth.

Gouin et al. (2011) published an assessment on how much polyethylene US citizens used in liquid soap and shower gel in 2009. 300 Mio US citizens used together 261 tonnes of micro particles in liquid soap and shower gel. That equals a daily consumption of micro particles from PE of 2.4 mg per US citizen.

Along with their use in the cosmetics industry, there are other applications for plastic microparticles. They are used as abrasive beads in detergents and cleaning fluids, and as a blasting abrasive in, for example, the surface cleaning of stainless steel. They are use as lubricants, separating agents, or as carriers for pigments, or to adjust the viscosity of hot melt adhesives. They are also used as lamination for glossy magazines or to protect fruit from getting pressure marks. Water softeners can also contain plastic micro particles. Special micro particles are used as vector for pharmaceuticals.

As well as microplastics produced directly in microscopic sizes to be used in cosmetics and other products, microparticles in many cases are secondary fragments produced by the breakdown of larger pieces of plastic. Plastic microparticles can originate, for example, from plastic packaging dumped in the environment, such as bags or boxes, or from plastic fibres from textiles, or particles released by tyre wear. The production and recycling of plastics also generates particles. Ryan et al. (2010) also record direct macroplastic pollution from ship waste.

Although the sources of microplastics are largely documented, until now no reliable data has been produced on the amounts of microplastics from cosmetics and other implementations, and other sources, actually enter the environment.

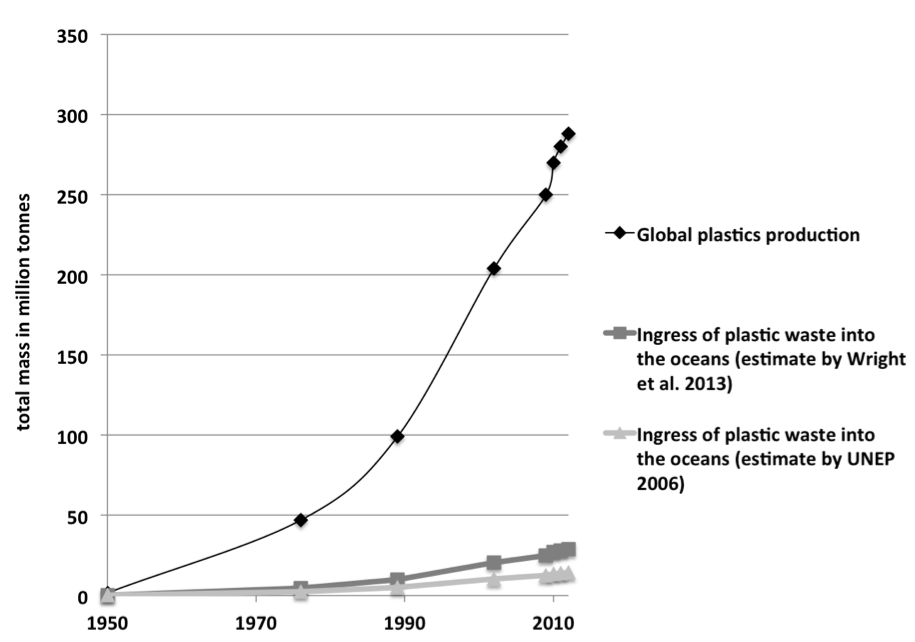

The United Nations Environment Programme refers to the estimate made in 1997 that in the 1990s, around 6.4 million tonnes of plastic debris entered the oceans annually, of which just short of 5.6 million tonnes came from shipping (UNEP 2006). Wright et al. 2013 estimate that, in total, around ten per cent of global plastics production will find its way into the ocean at some point. It follows that of the 288 million tonnes of plastic produced worldwide in 2012 (according to PlasticsEurope estimates), just short of 30 million tonnes will sooner or later enter the marine environment and serve as a potential source of microplastics (cf. Figure 1).

Consequences of microplastics

The presence of microplastics in the environment has a number of negative consequences for humans and the natural environment. If animals ingest pieces of plastic, large or small, mistaking them for food, a permanent feeling of satiety can result – and they starve to death. In experiments feeding mussels with microplastics, researchers demonstrated that plastic particles could penetrate the stomach lining and enter the bloodstream. Many plastic parts contain chemicals like softeners or flame-retardants. Some of these additives are harmful to fertility or imitate natural hormones. They are only weakly bound into the plastic matrix, and can easily leach out and impact plant and animal life. Long-lasting hydrophobic pollutants can attach to and accumulate on plastic microparticles. If marine organisms consume these particles, these contaminants can enter the food chain (Teuten et al. 2007) and ultimately cause harm to humans.

Are ecological plastics the solution?

Primary microparticles from cosmetics make up only a small part of the plastics in the oceans in absolute terms. Strategies designed to reduce the ever-increasing ‘littering’ of the world’s seas should therefore not focus solely on the use of these microparticles, but should apply to all kinds of plastic waste.

There are ways to reduce or, if it accrues, to increase material use of plastic waste in the future. The European Union relies on a five-level waste hierarchy which has been defined in the Waste Framework Directive 2008/98/EG from 19 November 2008. Above all, waste has to be avoided. If that’s not possible, it should be reused, than materially recycled. Only at the forth and second last step is waste to be used thermally and as a very last option to be deposited.

Cosmetics manufacturers can, however, eliminate long-lasting plastic microparticles from their products, or replace them with microparticles produced from other materials. Many of these companies are currently on the lookout for alternatives. Chemicals producers and traders already offer a selection (cellulose, wood chip, minerals).

Whether or not biodegradable polymers can be an option is an exciting and important question. Their use would be of interest above all because the existing production chain could be kept in use largely unaltered, and the functioning of the microparticles would also be a very close match for the plastics previously in use.

Polyhydroxyalkanoate (PHA), and polybutylene succinate (PBS), are potential candidates, as are polylactic acid (PLA) produced from maize starch, chitosan from chitin or casein from animal protein. Current studies suggest that PLA is probably not the best solution, whereas PHAs have real future potential (CalRecycle 2012). PHAs are natural thermoplastics, which degrade quickly in almost any environment (including in the sea). The greatest challenges lie in ensuring that breakdown occurs only after the product has been used, and in developing mass production.

In contrast, so-called ‘oxo-biodegradable’ plastics are no solution – in fact, they’re part of the problem. These plastics aren’t actually biodegradable. They contain predetermined breaking points that cause the polymers to fragment i.e. produce microparticles. Up to 80 per cent of the content (in terms of the original weight of the product) remains in the environment and can produce toxic effects (Narayan 2009).

Conclusions

Bio-based biodegradable plastics are currently not relevant to the market. The search for this kind of material is like chasing a ghost, according to microbiologist Richard Thompson, Plymouth University: “Chasing a ghost: It is possible that we produce a plastic product, which vanishes if it is not utilized anymore” (Thompson 2014). The material is supposed to meet requirements on stability, structure, colour or smell but on the other hand to lose all these properties as soon as it’s not used anymore. It is supposed to decompose in the dry and hot desert as well as in wet and salty seawater. This is a major challenge for material scientists and engineers to say the least.

Today bio-based plastics, which could be basically sufficient to the requirements, are already known (like PHA, see above). With an adequate political framework, optimization of there properties and mass production, this category of plastics could have a great future.

The availability of precise numbers on the amount of plastic microparticles used in cosmetics and other products is unsatisfactory. Due to the lack of data, it is difficult to establish the volumes in which these particles enter the environment, and what the predominant transport and release mechanisms are. Their accumulation in the oceans, on the seafloor, on beaches worldwide, and in numerous organisms (and the resulting adverse effects for both humans and nature) is receiving ever more public attention, and demands solutions.

Fragments from plastic debris that has entered the sea are a far greater source of damage. This means that if we want to decrease the amount of microplastics in the environment, and above all in the world’s oceans, it is not enough to focus on microplastics in cosmetics. Instead, measures need to be taken to drastically reduce the amount of plastic waste entering the environment in general – not just in Germany or the EU, but worldwide. The EU is pointing us in the right direction with its five-step waste hierarchy: reuse – reduce, recycle, incinerate (waste to energy) – (avoid) landfill.

At the same time other strategies should be pursued and strengthened. One possibility is the so-called substitution principle, the replaceing of conventional plastics with bio-based materials. Already a number of promising approaches exist with bio-based plastics like PHA, which are biodegradable in nearly every environmental condition.

Conference details

The nova-Institute is organising a conference entitled “Microplastics in the Environment – Sources, Consequences, Solutions” to take place on July 1st between 9am and 6pm at the Maternushaus conference centre in Cologne, Germany. Further information about the conference can be found at: www.bio-based.eu/mikroplastik

The work language is German.

References

Arthur, C.; Baker, J. & H. Bamford (2009): Proceedings of the international Research Workshop on the Occurrence, Effects and Fate of Microplastic Marine Debris. Sept 9-11, 2008. NOAA Technical Memorandum NOS-QR&R-30.

Barnes, D.K.A.; Galgani, F.; Thompson, R. C. & M. Barlaz (2009): Accumulation and fragmentation of plastic debris in global environment. In: Philosophical Transaction of the Royal Society B (biological sciences) 364: 1985-1998

Browne, M.A.; Crump, P.; Niven, S.J.; Teuten, E.; Tonkin, A.; Galloway, T. & R. Thompson (2011): Accumulation of Microplastic on Shorelines Worldwide: Sources and Sinks. In: Environmental Science & Technology 45: 9175-9179

CalRecycle – California Department of Resources Recycling and Recovery (2012): PLA and PHA Biodegradation in the Marine Environment. State of California, Department of Resources Recycling and Recovery, Sacramento, California

Gouin, T.; Roche, N.; Lohmann, R. & G. Hodges (2011): A thermodynamic approach for assessing the environmental exposure of chemicals absorbed to microplastic. In: Environmental Science & Technology 45: 1466-1472

JRC – Joint Research Centre (2013): Guidance on Monitoring of Marine Litter in European Seas – A guidance document within the Common Implementation Strategy fort he Marine Strategy Framework Directive. MSFD Technical Subgroup on Marine Litter. European Union, 2013

Leslie, H.; van der Meulen, M. D.; Kleissen, F. M. & A. D. Vethaak (2011): Microplastic Litter in the Dutch Marine Environment – Providing facts and analysis for Dutch policymakers concerned with marine microplastic litter. Deltares, the Netherlands

Narayan, R. (2009): Biodegradability… In: bioplastics MAGAZINE [01/09] Vol. 4: 28-31

PlasticsEurope – Association of Plastics Manufacturers (2013): Plastics – the Facts 2013. An analysis of European latest plastics production, demand and waste data. PlasticsEurope, Brussels

Ryan, P.G.; Moore, C.J.; van Franeker, J.A. & C.L. Moloney (2010): Monitoring the abundance of plastic depbris in the marine environment. In: Philpsophical Transactions of the Royal Society B 364, pp: 1999 – 2012

STAP – Scientific and Technical Advisory Panel (2011): Marine Debris as a Global Environmental Problem: Introducing a solutions based framework focused on plastics. Global Environment Facility, Washington, DC.

Teuten, E.L., Rowland, S.J., Galloway, T.S. & Richard C. Thompson (2007): Potential for plastics to transport hydrophobic contaminants. In Environmental Science and Technology 41, 7759-7764

Thompson, Richard C. (2014): The challenge: Plastics in the marine Environment. Environmental Toxicology and Chemistry 33: 6-8

UBA – Umweltbundesamt (2010): Abfälle im Meer – ein gravierendes ökologisches, ökonomisches und ästhetisches Problem. Umweltbundesamt, Dessau-Roßlau

UNEP – United Nations Environment Programme (2006): Ecosystems and Biodiversity in Deep Waters and High Seas. UNEP Regional Seas Reports and Studies No. 178. UNEP /IUCN, Switzerland

Wright, S. L.; Thompson, R. & T. S. Galloway (2013): The physical impacts of microplastics on marine organisms: A review. In: Environmental Pollution 177: 483-492

Source

nova-Institut GmbH, 2014-05-06.

Supplier

Institute for Environmental Studies (IVM)

nova-Institut GmbH

Umweltbundesamt

United Nations Environment Programme (UNEP)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals