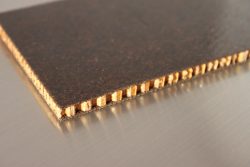

Whether they’re turned into dashboards, car door panels or airline service trolleys – wood and natural fibres such as cotton, flax fibre, hemp, jute and kenaf are gaining steadily in importance as bio-based composites. Not least because of their environmental benefits. From 22 to 24 September, COMPOSITES EUROPE 2015 in Stuttgart will present renewable raw materials for composites.

Working with the nova-Institut at the “bio-based composites” group stand for the second time, exhibitors will demonstrate just how great being sustainable can be when it comes to lightweight construction designs, materials and the most up-to-date production and automation solutions. Because the stand enjoyed such a successful debut, its next incarnation will be 50% larger. A total of 20 companies will be representing the biocomposites sector at the trade fair.

A first-time study conducted as part of the EU’s MultiHemp project revealed the ecological benefits of wood and natural fibres. Michael Carus, managing director of the nova-Institut, sums up the findings: “The carbon footprint of natural fibres is four times lower than that of conventional fibres.”

A first-time study conducted as part of the EU’s MultiHemp project revealed the ecological benefits of wood and natural fibres. Michael Carus, managing director of the nova-Institut, sums up the findings: “The carbon footprint of natural fibres is four times lower than that of conventional fibres.”

„Natural fibres are significantly less dense, which enables the production of very lightweight composites, like those already being deployed in high volumes by the automotive industry”, adds Dr. Asta Eder from the nova-Institut. Both experts will be available for discussions at the group stand.

(Go to bio-based.eu/ecology to view the findings of the study.)

The variety of exhibitors at the group stand reflects the types of products that can be made from natural fibres. Biowert, for example, is a company that specialises in processing meadow grass. In addition to natural fertilisers, the one-of-a-kind biorefinery also produces innovative plastics from meadow grass. Belgium-based TransFurans is a specialist for furfuryl alcohol, a chemical that’s both renewable and carbon-neutral because it’s gained from biomass. It’s deployed, for example, in the production of thermosets for sophisticated high-temperature applications. The JRS, J. RETTENMAIER & SÖHNE group of companies is all about researching, developing and processing high-quality organic fibres made from renewable plant-based raw materials. Products from cellulose or grain, fruit and wood fibres are turned into microfibres, compacted and granular materials, blends and special dosage forms.

The French company EcoTechnilin is also working on a variety of bio-based projects, including “variations of our FibriPreg technology, in which we combine our flax fleece with the furfural-based bioresin from TransFurans Chemicals in Belgium”, explains William Anthony, EcoTechnilin’s marketing director. Current products include FibriCars, which has thus far been deployed in cars such as the Jaguar F-TYPE, and FibriBoard, which is used by the automotive industry in seat backs and door panels. “We’ll show samples of our various bio-based products at COMPOSITES EUROPE. Our main focus will be on FibriRock, our aviation composite. We’ll have a complete service trolley at our stand and will show how biofibres have contributed to making it the lightest 50 kg capacity cart with the ability to pass the stringent new 21G tests.”

The Belgian company ISOMATEX specialises on enriched volcanic rock filament, among other products. In the production of stable mineral products, ISOMATEX is focussed on reducing environmental pollution to an absolute minimum and ensuring complete recyclability. FIMALIN is dedicated to representing companies from the entire linen production value chain in France all the way to COMPOSITES. Both companies will be exhibiting at the group stand.

“Natural fibres come with excellent technical characteristics, and they’re available in sufficient and stable quality at prices that are definitely competitive”, confirms Gabriele Peterek, PR manager of the German Agency for Renewable Resources (FNR). The FNR will provide information on all things biocomposites at the group stand. “Bio-based composites are one of our core subjects. In recent years, we’ve supported a number of different research projects, especially ones on using natural fibre-reinforced materials in the automotive sector. Our COMPOSITES EUROPE display will feature items from this segment, as well”, says Dr. Gabriele Peterek. According to the FNR, the current economic system will have to be reorganised in the foreseeable future – for both environmental protection and supply reasons. The use of natural fibre-reinforced materials, the agency adds, would be a great first step in that direction.

The European Industrial Hemp Association (EIHA) will also provide information on natural fibre solutions – specifically from industrially produced hemp. “Industrial hemp is known for its strong fibres. These are increasingly deployed by European carmakers to reinforce plastic parts used in the interior and to manufacture eco-friendly insulation and fleece materials”, says Dominik Vogt, the office manager of the European Industrial Hemp Association. “At our stand, we’ll touch on all the facets of the industrial hemp plant, i.e. pulp & paper, insulation, biocomposites & construction and food & feed. The focus, though, will of course be on natural fibre-reinforced plastics and biocomposites such as fibres, granular injection moulding materials and finished components made from hemp fibre-reinforced plastics for car interiors.”

New: bio!CAR Conference

In addition to the “bio-based composites” group stand, COMPOSITES EUROPE will for the first time host bio!CAR, a new conference for the automotive industry with a focus on bio-based materials in car manufacturing. The international gathering will debut at COMPOSITES EUROPE 2015 at the Exhibition Centre Stuttgart on 24 and 25 September. Organising the meeting will be bioplastics MAGAZINE in cooperation with trade fair organiser Reed Exhibitions, the nova-Institut and the German Federation for Reinforced Plastics AVK.

For details, please visit www.bio-car.info

COMPOSITES EUROPE to showcase composites industry trends

About 450 exhibitors from 25 nations will come to the Exhibition Centre in Stuttgart from 22 to 24 September to present composites industry innovations for automotive engineering, aerospace, boatbuilding as well as the wind energy, construction and other sectors. A key focus will be on automation solutions that enable high-volume production processes for manufacturing composites components. Some 11,000 lightweight construction decision-makers are expected to attend the 10th COMPOSITES EUROPE, which is organised by trade fair organiser Reed Exhibitions in cooperation with the European industry association EuCIA, the German Federation for Reinforced Plastics AVK, the VDMA Forum Composite Technology and the international trade magazine Reinforced Plastics.

Kicking off COMPOSITES EUROPE 2015 will be the “1st International Composites Congress (ICC)” taking place at the International Congress Center Stuttgart on 21 and 22 September 2015. Bringing together the leading composites experts from across Europe, the conference will document innovations in the fibre-reinforced plastics segment. The Congress will be organised by the trade association Composites Germany.

nova-Institut contacts

Dipl.-Phys. Michael Carus

Phone: +49-(0)2233-48-14 40

Email: michael.carus@nova-institut.de

Dr. rer. nat. Asta Eder

Phone: +43 (0)676-3631-459

EMail: asta.eder@nova-Institut.de

Source

COMPOSITES EUROPE, press release, 2015-05-13.

Supplier

AVK – Industrievereinigung Verstärkte Kunststoffe e.V.

bioplastics MAGAZINE (Zeitschrift)

COMPOSITES EUROPE

Composites Germany

EcoTechnilin

European Industrial Hemp Association (EIHA)

European Industry Association EuCIA

Fachagentur Nachwachsende Rohstoffe e.V. (FNR)

Fimalin

ISOMATEX S.A.

J. Rettenmaier & Söhne GmbH & Co.

nova-Institut GmbH

Reed Exhibitions

VDMA Fachverband Kunststoff- und Gummimaschinen

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals