Bridgestone Corporation and ENEOS Corporation today announced the launch of a joint research and development project aimed at achieving the social implementation of “chemical recycling technologies that enable precise pyrolysis of used tires”*1. This initiative contributes to accomplishing the shared sustainability vision of both companies.

Tire demand is expected to grow in the future in conjunction with rising automobile and transportation demand.2 Synthetic rubber is one of the primary materials used when producing tires and is generally produced from petroleum today. Used tires are also utilized as fuel mainly through thermal recovery3 in Japan and this utilization method emits CO2 consequently.

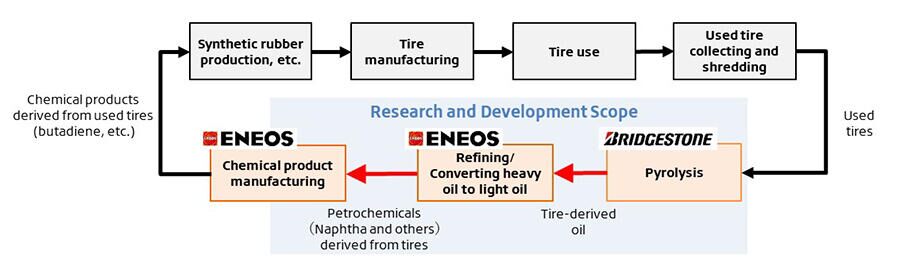

Through this project, Bridgestone and ENEOS aim to develop a recycling business that will convert used tires to raw materials, enabling a more sustainable society. The joint project will work to develop chemical recycling technologies for used tires by merging the advanced rubber and polymer material design technologies Bridgestone has cultivated through its tire and rubber business with the crude oil refining technologies and foundational basic chemical product manufacturing technologies of ENEOS.

Specifically, the companies will engage in demonstrations for social implementation of chemical recycling technologies for achieving high-yield production of chemical products, such as butadiene, a raw material used in synthetic rubber.4 These technologies will entail breaking down used tires through precise pyrolysis to produce petrochemical feedstocks (naphtha5, etc.) which in turn will be utilized to manufacture petrochemical products. The large-scale demonstrations will be advanced toward 2030 with the goal of achieving mass production and swift commercialization. Bridgestone and ENEOS, as leaders in the tire and rubber industry and the petroleum and petrochemicals industry respectively, are working to enhance increased resource circulation and reduced CO2 emissions across the value chains of their industries toward the future.

This project is one of two research and development (R&D) projects under the initiative called “developing chemical product manufacturing technologies utilizing used tires” promoted by the New Energy and Industrial Technology Development Organization (NEDO) of Japan67 and adopted as part of “the Green Innovation Fund” of NEDO.

The Ministry of Economy, Trade and Industry (METI) of Japan decided to develop the Green Innovation Fund toward the goal of achieving carbon neutrality by 2050, the sustainability goal of Japanese government. The plan aims to accelerate structural transformation in the energy and industry sectors, and innovation through ambitious investment. The Green Innovation Fund continuously supports companies and other organizations that address challenges to achieve sustainability goals as part of their business through R&D, demonstrations, and social implementation of the outcomes for the coming ten years.

The Bridgestone Group has defined its vision as to provide social value and customer value as a sustainable solutions company toward 2050 and is advancing its Mid-Long Term Business Strategy and Mid Term Business Plan (2021-2023)8 to accomplish this vision. A core aspect of this endeavor will be accelerating initiatives for realizing its Sustainability Business Framework9, which is designed to link its business model to efforts to promote the circular economy and carbon neutrality across the value chain. The Bridgestone Group is developing tire businesses that entail producing and selling tires and solutions businesses that provide value to customers at the tire use stage. In addition, the Bridgestone Group began exploration and R&D related to recycling businesses for converting tires into raw materials in 2021.

One of the ENEOS Group’s envisioned goals stated in our Long-Term Vision to 2040 is contributing to the development of a low-carbon, recycling-oriented society through the enhancement of environmentally conscious business. For the petroleum and petrochemical industry, which uses materials derived from fossil fuels, promotion of renewable resources utilization is required to contribute to the development of a low-carbon, recycling-oriented society. As part of our efforts, ENEOS is using its refineries to promote oil recycling.

Both companies are combining the technologies and expertise they have fostered in their respective industries to promote carbon neutrality in tire-related industries and to contribute to the realization of a more sustainable society.

Shuichi Ishibashi, Global CEO and Representative Executive Officer of Bridgestone Corporation: “The Bridgestone Group places sustainability at the core of management and business and is practicing co-creation with a variety of partners to accomplish its vision of providing social value and customer value as a sustainable solutions company. I am excited to be able to embark on this co-creation project with ENEOS, a leading company in the petroleum and petrochemical industry. This project represents a significant step forward in our quest to increase resource circulation and promote carbon neutrality in the tire and rubber industry. Through this R&D project, we aim to develop our recycle business that will “renew” used tires to raw materials. I am confident that the social implementation of technologies for this purpose will help us realize our Sustainability Business Framework. Going forward, we will continue to promote various co-creation projects to contribute to the realization of a sustainable society.”

Katsuyuki Ota, Representative Director, President of ENEOS Corporation: “This joint project helps to contribute to the development of a low-carbon, recycling-oriented society, one of the ENEOS Group’s envisioned goals stated in our Long-Term Vision to 2040. We are confident that the joint research and development project with Bridgestone, a leading company in the tire and rubber industry, will further promote the use of renewable resources.

Working with our partners across the entire supply chain, we will continue to make every effort to achieve a recycling-oriented society using the technologies we have developed in our existing businesses over many years.”

*1 Chemical recycling entails treating used materials with chemicals to convert them into other chemical substances to be recycled, as opposed to reusing them as is.

*2 Japan Association for Chemical Innovation article on rubber-related basic chemical product manufacturing strategies as part of the chemical industry’s innovation strategies and vision for society 30 years from now (in Japanese only) http://www.jaci.or.jp/public/page_03.html#rubber

*3 Thermal recovery entails recovering heat energy from used resources.

*4 Synthetic rubber is one of the primary materials used when producing tires. This material is currently generally manufactured using petroleum.

*5 Naphtha is a crude oil-derived substance that resembles gasoline. Thermal decomposition of naphtha can be used to create raw materials for producing items such as plastic, synthetic rubber, synthetic fibers, coatings, and synthetic detergents.

*6 Project for Developing Chemical Product Manufacturing Technologies Utilizing Used Tires Advanced by Bridgestone and ENEOS, Adopted as part of “the Green Innovation Fund / Development of Technology for Producing Raw Materials for Plastics using CO2 and Other Sources Projects” of NEDO (in Japanese only) https://www.nedo.go.jp/news/press/AA5_101517.html

*7 Please refer to the following website for information on a detail about “the chemical recycling technologies to achieve high-yield production by decomposing at low temperatures and depolymerization of used tires”, the other program of the two R&D projects under the initiative called “developing chemical product manufacturing technologies utilizing used tires” adopted as part of “the Green Innovation Fund / Development of Technology for Producing Raw Materials for Plastics using CO2 and Other Sources Projects” of NEDO.

https://www.bridgestone.com/corporate/news/2022021801.html

*8 Please refer to the following website for information on the progress of Bridgestone’s Mid-Long Term Business Strategy and Mid-Term Business Plan (2021-2023). https://www.bridgestone.com/ir/library/strategy/index.html

*9 Please refer to the following websites for information on Bridgestone’s Sustainability Business Framework.

https://www.bridgestone.com/corporate/news/2021011401.html

https://www.bridgestone.com/ir/library/strategy/pdf/ENG_yearendpressconference2020.pdf

About Bridgestone Corporation

Bridgestone is a global leader in tires and rubber building on its expertise to provide solutions for safe and sustainable mobility. Headquartered in Tokyo, the company employs approximately 140,000 people globally and conducts business in more than 150 countries and territories worldwide. Bridgestone offers a diverse product portfolio of premium tires and advanced solutions backed by innovative technologies, improving the way people around the world move, live, work and play.

About ENEOS Group and ENEOS Corporation

Under ENEOS Holdings, Inc., the ENEOS Group has developed businesses in the energy and nonferrous metals segments, from upstream to downstream, with about 700 consolidated group companies and 40,000 employees. ENEOS Corporation, one of the principal operating companies in the Group, is engaged in a broad range of energy businesses, which include petroleum products, for which the company holds the largest market share in Japan, as well as petrochemicals, electricity, lubricants, coal, renewable energy and hydrogen.

Source

Bridgestone, press release, 2022-02-18.

Supplier

Bridgestone Corporation

ENEOS Corporation

METI Ministry of Economy, Trade and Industry

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals