- Borealis is taking another important step towards expanding its advanced mechanical recycling capabilities.

- A commercial-scale plant will be operational in 2025, with the capacity to produce over 60 kilotonnes of circular solutions and compounds per year.

- The design of the plant will be based on BorcycleTM M, Borealis’ advanced mechanical recycling technology platform.

Borealis is designing a first-of-its-kind commercial-scale advanced mechanical recycling plant to be located in Schwechat, Austria. The plant will be based on Borealis’ own BorcycleTM M technology, which transforms polyolefin-based post-consumer waste into high-performance polymers suitable for demanding applications. This represents another tangible step forward on Borealis’ path to net zero.

The new plant will have capacity to produce over 60 kilotonnes of advanced mechanical recycled polyolefin solutions and compounds per year. For customers and end-consumers, this will mean an increase in the availability of high-quality recycled plastic products.

The decision was based on positive feedback from the market on recycled polyolefins delivered by a demonstration plant based on the same technology. This plant was located in Lahnstein, Germany, and operated by Borealis, Tomra and Zimmermann.

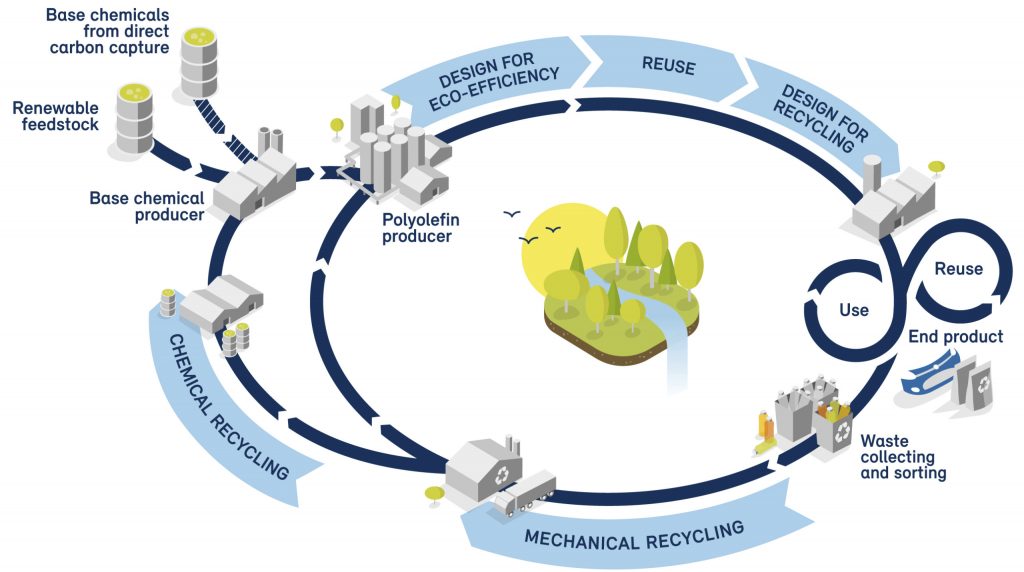

Mechanical recycling plays a key role in Borealis’ approach to achieving circularity, as shown in the integrated cascade model. The new plant will expand Borealis’ capabilities in this area, following on from the acquisitions of plastic recyclers mtm plastics in 2016, and Ecoplast Kunstoffrecycling in 2018.

The front-end engineering design (FEED) stage for the plant will be carried out by Nextchem, specialists in the field of green chemistry and technologies for the energy transition. Upon successful completion of FEED phase, Borealis expects to take a final investment decision in the second half of 2023 and start construction by the end of 2023. The first volumes of recycled polyolefin products are expected in 2025.

The plant will support Borealis to deliver on its sustainability commitments, which target a supply capacity of 600 kilotonnes of circular products and solutions globally by 2025, further increased to 1.8 million tonnes by 2030.

“With our purpose to reinvent essentials for sustainable living, Borealis is committed to rapidly increasing the share of recycled content across a wide range of high-performance polyolefins. Proof-in-point of the EverMinds mindset, this step demonstrates how innovative technology continues to advance circularity,” says Lucrèce Foufopoulos-DeRidder, Borealis Executive Vice President of Polyolefins, Circular Economy Solutions and Innovation & Technology.

About Borealis

Borealis is one of the world’s leading providers of advanced and sustainable polyolefin solutions and a European front-runner in polyolefins recycling. In Europe, we are a market leader in base chemicals and fertilizers. We leverage our polymer expertise and decades of experience to offer value adding, innovative and circular material solutions for key industries such as consumer products, energy, healthcare, infrastructure and mobility.

In re-inventing essentials for sustainable living, we build on our commitment to safety, our people, innovation and technology, and performance excellence. We are accelerating the transformation to a circular economy of polyolefins and expanding our geographical footprint to better serve our customers around the globe.

With head offices in Vienna, Austria, we employ 6,900 employees and operate in over 120 countries. In 2021, we generated total sales of EUR 12.342 EUR billion and a net profit of EUR 1,396 million. OMV, the Austria-based international oil and gas company, owns 75% of our shares, while the remaining 25% is owned by a holding company of the Abu-Dhabi based Mubadala. We supply services and products to customers around the globe through Borealis and two important joint ventures: Borouge (with the Abu Dhabi National Oil Company, or ADNOC, based in UAE); and Baystar™ (with TotalEnergies, based in the US).

About Borealis EverMinds

Launched in 2018, EverMinds™ is an umbrella brand uniting the wide range of Borealis activities and initiatives aimed at making plastics more circular. As a dedicated platform, EverMinds promotes a circular mind-set among all Borealis stakeholders. The platform encompasses proprietary Borealis technologies as well as established brands such as Purpolen™ and Dipolen™. It facilitates deeper collaboration between Borealis and its partners in order to develop innovative and sustainable polyolefins solutions based on the circular model of recycling, re-use and design for circularity. EverMinds also extends to pioneering corporate programmes such as Project STOP, and engagement in industry initiatives like the Polyolefins Circular Economy Platform (PCEP), and Project CEFLEX.

Source

Borealis, press release, 2022-10-19.

Supplier

Borealis Polyolefine AG

NextChem

Tomra

Zimmermann Recycling & Transporte

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals