On its third year of work, the AFTER-BIOCHEM’s consortium is pleased to share the following key outcomes of the project: The industrial start-up, the commercial commitments confirmed, and the replication process unlocked.

Located in Carling Saint-Avold, France, AFYREN NEOXY plant is the demonstration of AFTER-BIOCHEM’s proof of concept: the industrial scale-up of Afyren’s biobased acids production, with the objective to reach 16,000 tons at full capacity. This biorefinery, which produces biobased carboxylic acids from sugar beet co-products, is a first of its kind flagship biorefinery.

One year after the start of its industrial commissioning, the plant has already a high amount of its targeted production volume pre-sold, with confirmed commitments for orders totaling €165 million in revenue. What testifies about the trust from industrials in a context where the

tightening of sustainability targets in Europe and in the world, makes supply of safer chemicals building blocks, a major stake.

On the other hand, several locks are lifted by the action of the project partners and allow to consider the replication phase of the plant with less risks.

AFTER-BIOCHEM: an industrial scale -up leading to a commercial success, and a replication process unlocked

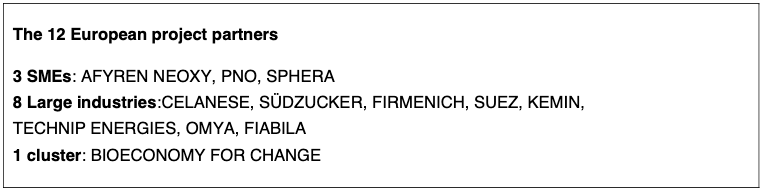

The action of the 12 partners of AFTER-BIOCHEM on the entire value chain of the project led to reach important objectives defined ahead of its launching. Particularly, the industrial scale-up of the production of Afyren’s acids and the lifting of locks to the replication of the plant.

Industrial start-up:

The highlight of the 2022 was the industrial start-up and inauguration of the plant AFYREN NEOXY in Carling-Saint Avold, in the Grand Est region of France. An audience of around 200 people gathered for this celebration in September 2022. Today, the teams are fully mobilized to ensure the reliability of certain unit stages, with a view to launching industrial production and invoicing customers. Initially scheduled for the end of 2022, delivery of the first batches was postponed to allow operations to be stabilized, without impacting contractual commitments.

Commercial developments

Market expectations are very high; Afyren has announced that all strategic customers haveconfirmed their confidence in the AFYREN project, with commercial commitments for 75%1 of AFYREN NEOXY’s annual production of acids and 100% of fertilizer. Those commitments represent total cumulative revenue of more than €165 million2, to be recognized over the coming years.

Replication process:

The initial objectives of the project include both preparation and facilitation of a future replication of the plant. With the objective to support the installation of production units close to industrial end-users, studies are produced and updated by B4C and PNO, in the framework of the project. Furthermore, SUEZ and Terrial will proceed their work on the characterization and the validation of co-products. The investigation is led on the identification of feedstocks that fit best to Afyren’s technology to determine optimal sites for the implementation of the coming plants.

Project’s next steps

Once industrial production begins, AFYREN plans to gradually ramp up volumes to produce 16,000 tons of carboxylic acids per year at full capacity. The coming months will serve to consolidate the results of additional sustainability assessments led by Sphera on carbon footprint, material footprint and societal impact. Another focus will be put on the dissemination of the project results through the participation to events with scientific and industrial attendance.

1 Of which 71% contractualized and 5%+ in pe-contract stage (MoU, LoI)

2 Based on contractualized part only – volumes over the duration of the contract x selling price

About AFTER-BIOCHEM

AFTER-BIOCHEM is a unique opportunity to turn current agricultural processing co-products into new product streams. The project core technology is based on 10 years of R&D at AFYREN. The technology can turn biomass into high added-value and natural products using its all-in-one cutting-edge fermentation process based on natural micro-organisms (100% GMO-free process and products). The project also implements a “zero waste” strategy based on an optimized production process; all the fermentation outputs are valorized into valuable products: seven organic acids and one mineral coproduct that can be used respectively as ingredients and fertilizer. The biobased and natural

compounds have applications in various markets such as food and feed, fragrances and flavour, personal care, pharmaceuticals, and industrial chemicals.

AFTER-BIOCHEM has several environmental impacts. Indeed, its integrated approach reduces CO2 emissions by five, compared to traditional fossil-based organic acid production. Furthermore, the “zero waste” strategy results in a production process free of industrial process waste and directly avoid the releases of substances hazardous to the environment and health. Finally, AFTER-BIOCHEM reduces the dependence on non-renewable, unsustainable resources by valorizing agricultural by-products. AFTER-BIOCHEM’s biorefinery AFYREN NEOXY, is built in the Grand-Est region.

Duration: 48 months (From May 2020 to April 2024) | Total budget: € 20M | Total cost: € 33M

AFTER-BIOCHEM received € 20M funding from the Bio-based Industries Joint Undertaking (BBI JU) under grant agreement No 887432. The JU receives support from the European Union’s Horizon 2020 research and innovation program and the Bio-based Industries Consortium.

Source

AFTER BIOCHEM, press release, 2023-04-27.

Supplier

AFTER-BIOCHEM consortium

AFYREN

Bio-based Industries (BBI) Joint Undertaking

Bio-based Industries Consortium (BIC)

Bioeconomy for Change

Celanese

Fiabila

Firmenich SA

Omya AG

Südzucker AG

SUEZ Groups

Technip Energies

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals