Using state-of-the-art plasma technology to make cheap fertilizer for small farmers. It may sound like magic, but it has now become reality. Researchers at Eindhoven University of Technology (TU/e) have built a small plasma-powered plant that produces nitrogen-based liquid fertilizer only using sun, water and air. “The plant is easy to set up, sustainable and very efficient”, says TU/e researcher Fausto Gallucci, who together with partners in Africa, Germany and Portugal has done successful tests of the device in Uganda. “We now want to bring the mini-plant to the market, so that it becomes available to farmers around the world”.

Feeding an increasing world population is a huge challenge. Forecasts say there will be 8.6 billion people on our planet in 2030, and almost 10 billion in 2050. Artificial fertilizers, in particular nitrogen-based fertilizers, play a key role in meeting this challenge.

Vital nitrogen

Nitrogen is one of the three main macronutrients used by plants to grow (next to phosphorus and potassium. In 2015 about one in every two humans was fed by food that was cultivated using nitrogen-based fertilizer, a proportion that is expected to increase over the coming years. While widely available in the developed world, artificial fertilizers are not as common in the developing world. In Africa, where 60 percent of all farmers have less than one hectare of land at their disposal, farmers often don’t have the money to buy the stuff. In addition, fertilizers are often produced by big multinationals, who only deliver in bulk and from central locations.

Low-tech

It is here that the Africa project of Leap-Agri comes in. It uses a small-scale reactor to make liquid nitrogen-based fertilizer that can be used by any farmer who has access to sunlight and water. While the technology behind it is quite state-of-the-art, the application is very low-tech. “We sent a system based on our plasma reactor to the National Agricultural Research Organisation (NARO) in Uganda that had never worked with plasma technology before, and they were able to produce fertilizer within a month”, says Fausto Gallucci, professor at the department of Chemical Engineering and Chemistry.

“Our system is small, simple and very fast. Once you switch it on, it is really a matter of seconds before it begins to produce fertilizer. This makes it also very flexible: you only run it when the sun is shining and you need fertilizer”.

Cool plasma!

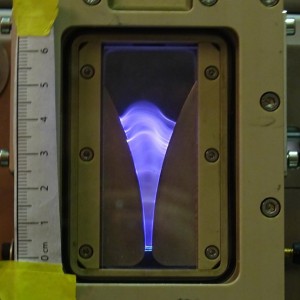

So how does this ‘magical’ device work? Professor Gallucci explains: “Our mini-plant uses plasma technology. Plasma, as you know, is the fourth state of matter and consists of ionized atoms and molecules. You may be familiar with it from lightning or neon signs, which both consist of plasma”. The plasma used in the fertilizer plant is non-thermal: while the electrons that drive the reaction reach extremely high temperatures, the gas that surrounds can stay relatively cool. This of course saves energy. It makes plasma technology an attractive alternative to the traditional way of producing nitrogen, the so-called Haber–Bosch process, which requires both high pressure and high temperatures. It is estimated that the Haber-Bosch process consumes 1 to 2 percent of the world total energy, emitting some 300 million tons of CO2 every year into the air.

Fixing the nitrogen

Making nitrogen-based fertilizer in a plasma reactor involves a process known as nitrogen fixation. While 78 percent of the air consists of N2, the gas does not react with other elements (it is chemically inert). This makes it hard for plants to use.Nitrogen fixation solves this problem. It converts the nitrogen (N2) from the air into NOx, which in turn reacts with oxygen and water to form nitrate (NO3-). This can then be used as an ingredient for liquid fertilizer.

“To get the conversion process started”, explains Sirui Li, researcher in the group of professor Gallucci, “the N2 molecules first have to be ‘activated’ by introducing an electrical charge. This ensures that the bonds that hold the nitrogen atoms together are broken, creating a plasma.” In the case of the Leap Agri mini-plant, the electricity for plasma generation is provided by solar energy, a cheap and sustainable source widely available in developing countries.

Efficient and accessible

The process is highly efficient: it produces a liquid fertilizer with a high level of nitrate that can be readily assimilated by plants. An analysis was made in Uganda by NARO researcher Stella Kabiri, who compared this fertilizer with other fertilizers on the local market. The result showed the nitrate content to be about 20 percent, which is 14, 42 and 51 percentage points higher than the solid fertilizers Ammonium nitrate, NPK and Urea respectively.

“More importantly, the liquid fertilizer can be produced on-site and on-demand, so that each farmer can choose exactly the amount of fertilizer and nitrate content that she needs for her crop and plot of land”, says Sirui Li.

One day, smallholders in Africa will be able to buy their own fertilizer unit, either individually or collectively as a village.

At present the cost of the mini-plant is still quite high (some 70,000 euros), but Gallucci expects the price will come down considerably once it is being produced on a larger scale.

“One day, smallholders in Africa will be able to buy their own fertilizer unit, either individually or collectively as a village. The collective can then rent out the mini-plant to their members, or sell the fertilizer to other villages”.

Spin-off

Spin-off

Gallucci and his partners have started a TU/e spin-off 4th State Technologies to bring the mini-plant to the market. He expects the device will be available within the next three to five years, after the necessary certification process has been finished. The new company will also explore other promising applications of plasma technology, including the capture and reuse for chemical production of CO2. The Africa project is a collaboration of TU/e, the National Agricultural Research Organisation (Uganda), the Soil Research Institute (Ghana), the Nelson Mandela University (South Africa), Fraunhofer Research Association (Portugal), and Evonik (Germany). It was funded by the EU as part of the Leap-Agri program.

Source

Technische Universiteit Eindhoven, press release, 2021-02-18.

Supplier

4th State Technologies

CSIR - Soil Research Institute (Ghana)

Evonik Industries AG

Fraunhofer-Gesellschaft

Leap-Agri

National Agricultural Research Organisation (Uganda)

Nelson Mandela Metropolitan University (NMMU)

Technische Universiteit Eindhoven

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals