Global warming and environmental crisis due to anthropogenic activities call for the rapid implementation of measures to reduce the global carbon footprint. Carbon dioxide (CO2) capture and recycling through electrochemical reduction (electrolysis) may have a critical role when it comes to defossilizing the production of commodity chemicals.

While several transformation routes are being explored, CO2 electrolysis targeting carbon monoxide as reaction product is close to commercial viability, with state-of-the-art electrolysers reaching high performance. The so-called ‘zero-gap’ electrolysers with an anion-exchange membrane (AEM) – see text box – is the cell setup closest to meet commercial requirements. However, such devices still suffer from operation issues mainly due to the build-up of carbonate salt precipitates at the cathode and electrode flooding.

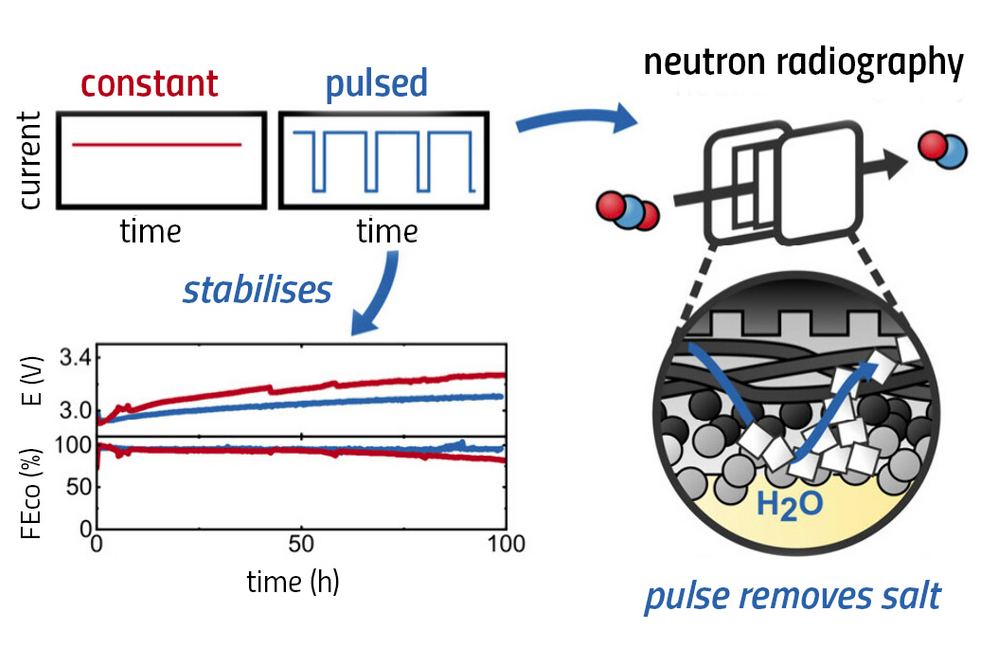

A recently published study examines the water transport in a CO2 electrolyser during operation. ILL’s instrument NeXT was used to obtain high-resolution neutron images at a pixel size of 4.2 μm of the water content in the cell, coupling the radiographic data with the overall electrochemical performance. The influence of gas humidification was studied, and pulsed operation is compared with constant current operation in 100 hours long measurements.

‘This is the first quantitative operando analysis of the water management in a CO2 electrolyser via high-resolution neutron imaging under industrially relevant working conditions’ says Joey Disch (University of Freiburg, Germany), who led the project, adding: ‘Operando studies play a vital role in understanding CO2 electrolysers and neutron imaging is an excellent method for operando investigation of water dynamics’.

’For distinguishing the water distribution in the vicinity of the 20 μm thick membrane, one of the main challenges was to achieve a spatial resolution of around 6 μm along the through-plane direction of the membrane assembly while still providing enough neutrons to achieve a decent temporal resolution in the order of 10 s’, explains Lukas Helfen, ILL scientist and NeXT co-responsible.

‘Along with an optimised neutron set-up, a customized electrolysis cell fixture from the University of Freiburg was used, with a smaller width and thus a smaller area, in order to reduce beam hardening and other image-degrading effects,’ explains Alessandro Tengattini, also co-responsible of NeXT, emphasising that ‘Each component within the electrolysis cell can be identified distinctly in the neutron images.’

CO₂ electrolyser cells in a nutshell

Anion-exchange membranes (AEM) transport anions (such as hydroxide, OH–) from the cathode to the anode. In ‘zero-gap’ cells there is no gap between cathode, membrane and anode, which decreases the distance for ion transport. Efficiency depends on the electrodes, membrane and catalyst used and on the reaction conditions. © ILL

The management of water in an electrolyser is shaped by continuous supply or removal of water through the gas feed, diffusion to the cathode, consumption in the reactions at the cathode and transport to the anode. The amount of water in the ion exchange membrane is critical for performance: lack of water reduces ion transport, excess hinders CO2 supply to the catalyst layer.

It has been previously found that a strategy to increase the stability is pulsed operation of the electrolyser: the repeated application of a potential, with brief resting periods in between, mitigates salt precipitation and extends the operational lifetime.

‘Pulsed operation was found to have an influence on the water management inside the cell – during the rest periods, both the water-consuming electrochemical reactions at the cathode and the drag through the membrane are stopped. However, the effect was still to be investigated, says Luca Bohn (University of Freiburg, Germany), the first author of the study.

The cell was operated at both constant current and pulsed electrolysis, with 1 minute breaks after every 10 minutes of operation, under 34% and 100% relative humidity (RH).

‘The results demonstrate that pulsed operation increases stability, even with low electrolyte concentrations’, reveals Bohn, concluding: ‘During the resting period, pulsed operation introduces additional water to the cathode, which facilitates the removal of salt precipitates and mitigates uncontrolled electrode flooding,’ concludes Bohn.

Indeed, neutrons have shown that during the brief rest periods the amount of water at the cathode increases, especially at higher RH, which dissolves carbonate precipitates, preventing accumulation. While high efficiency is continuously achieved at lower RH, CO2 transport gets limited under 100% RH due to the increase in water content. At constant current, on the other hand, multiple flooding events are observed, especially under high humidification.

The researchers point out that optimising the pulse strategy parameters and the electrolyte could still lead to improvements in performance. Parameters like the potential during the resting period, the timing of the pulses, and different waveforms should be explored. Most importantly, the strategy’s transferability to cell stacks should be explored. The work now published is a first step rather than a final one.

Reference

High-Resolution Neutron Imaging of Water Transport in CO2 Electrolysis during Pulsed Operation; ACS Energy Lett. 2025, 10, 2, 975–981; DOI: 10.1021/acsenergylett.4c03003

Research Highlight in Nature catalysis: Pulsed electrolysis through neutron lenses

Source

ILL, press release, 2025-03-19.

Supplier

ILL - Neutrons for Society

Universität Freiburg

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals