Al last, the need to work towards zero-emission construction seems to dawn on the construction trade. Not an easy task, as the volume of building projects around the world is still growing. But at least, some in the branch have started thinking about how to achieve this goal.

8% of world-wide CO2 emissions

A recent issue of Knowable Magazine illustrates how difficult it will be to turn around a conservative sector that produces 8% of global carbon dioxide emissions. Our present brands of cement and concrete have all been precisely tuned towards the varying requirements of the construction trade. Therefore, phenomena so far-fetched like climate change have difficulty convincing the sector. But as regulatory pressures mount, and as official policy formulates as its goal to reach zero emissions by 2050, the sector will need to rethink its basic technology.

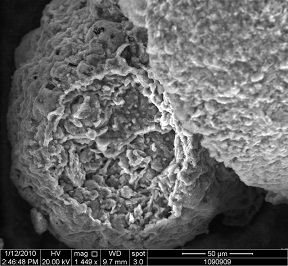

To this issue, we already devoted several articles. We wrote about a new kind of cement, developed by engineers of Drexel University in Philadelphia, that reduces carbon dioxide emissions by 93%. It mainly uses limestone and industrial slag. We wrote about concrete that contains bacteria that will seal cracks, preventing steel to corrode. And about cheaper formulations of concrete based on local resources, directly applicable in developing countries. More recently, we wrote about a material still in development, concrete containing graphene – which would reduce material requirements and be stronger.

Although concrete used in Roman times has proven to be incredibly strong – with buildings like the Pantheon in Rome that withstood two thousand years – the construction trade took another turn in the nineteenth century. It is now based on calcium oxide, produced from common limestone in kilns at high temperatures. These kilns emit carbon dioxide from two major sources – the fuel that produces the heat and the calcium carbonate that decomposes. But as the world is on the road to zero carbon dioxide emissions, the construction trade will have to follow suit.

Construction without CO2 emissions?

That is easier said than done. The world uses a very large amount of cement and concrete, and will continue to do so for quite some time. Important nations like China and India are in the middle of a construction boom. Are there alternatives available in the short term (well before 2050) that could allow us to go on constructing homes and buildings; without the emissions that go with this today?

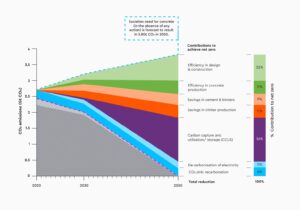

Major representative of the industry believe that there are. Knowable Magazine mentions the Global Cement and Concrete Association and the Portland Cement Association that have now published detailed road maps for reducing that 8 percent to zero by 2050. Strategies based on emerging technologies and underutilized practices. For some companies venture into this uncharted territory. For instance, we could tackle the 40% CO2 released for heat production by switching to electric heating; or by using hydrogen.

For the remaining 60%, the carbon dioxide released through decomposition of limestone, a whole array of technologies is in development. We could reduce emissions by 10% by adding some powdered, unbaked limestone to the final product. We could substitute industrial waste products like blast-furnace slag or fly-ash from coal-fired power plants, for fresh limestone. Add another 15 to 20%.

Technologies still in development

But the major part of CO2 emission reductions will have to come from more radical innovations. Mainly from technologies still in development. Among the best developed new techniques is the application of geopolymers, that result from treating silicon and aluminium oxides (both in ample supply) with alkaline solutions. These are tricky to handle, but they are strong and would reduce CO2 emissions by as much as 80%. Another strategy, according to Knowable Magazine, would be to use concrete more efficiently. Or to reserve stronger (high-cement) mixes for applications where they are really required. Or simply to reuse building materials.

Other options for the construction trade are more high-tech. We could use 3D printing for construction purposes. Using concrete for sure, but in such a way that this is only applied where required for strength and safety; if necessary reinforced with steel wires – savings up to 50%. Or use graphene reinforced concrete – with the same effect on CO2emissions. Or even completely substitute mass timber for concrete – a solution that has drawn a lot of attention. Mass timber technology has developed in such a way that we can now even construct high-rise buildings with it. No need for CO2 emitting building technologies anymore! Knowable Magazine figures that making use of all these options, CO2production from the construction trade might well be reduced to zero by 2050.

Radical innovations

Still, reviewing the options presented, it strikes us that almost none of the options mentioned earlier by us, return in the enumeration in this article. It doesn’t mention the mixtures developed by the researchers of Drexel University, that don’t require heat in production and that will release almost no CO2. Nor the self-healing concrete (that will protect the steel bars) developed at Delft Technical University in the Netherlands. The concrete produced by bacterial action on the raw materials. Concrete on the basis of volcanic ashes, as used in the still-standing buildings created by the ancient Romans. Concrete on the basis of raw limestone, well suited for many construction projects in developing countries.

There are many options available! The building trade might well cast its net a little wider, in its search for alternatives. Not just look for process improvements, but have an eye for radical innovations as well.

Author

Diederik van der Hoeven

Source

Supplier

Drexel University

Portland Cement Association

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals