Toray Industries, Inc., announced today that it will adopt the mass balance approach (see note 1) from April this year, in manufacturing its TORAYLON™ acrylic staple fiber. This approach attributes characteristics derived from both biomass and plastic waste. The company has already obtained ISCC (International Sustainability & Carbon Certification) PLUS certification for this product.

Toray’s fibers & textiles business strategy focuses on expanding in growth areas by developing high-value-added, high-performance products that employ environmentally-conscious materials. The company is thus working with both recycled material as well as bio-based materials, particularly for nylon and polyester fibers. Acrylic fibers have been a challenge in this respect because of a lack of waste resource of this single material. The mass balance approach will enable Toray to offer high-value-added TORAYLON™ that is also environmentally-conscious.

The company will push forward with life cycle assessment (note 3) verification with supply chain partners and apply for a review for inclusion in the Higg Index (note 4).

Under the Toray Group Sustainability Vision, the company has made realizing a world in which resources are managed sustainably one of its goals for 2050. It has undertaken companywide efforts to address issues such as resource depletion, marine pollution caused by plastic waste, and carbon dioxide emissions by developing a wide range of technologies. These technologies include recycling discarded plastic products and processing waste, using bio-based materials, and utilizing renewable energy. Toray Group has also adopted the mass balance approach to promote resource recycling and the use of bio-based materials.

Toray will continue to pursue R&D to realize a sustainable, circular society as part of ongoing efforts to realize its corporate philosophy of “contributing to society through the creation of new value with innovative ideas, technologies and products.”

Notes

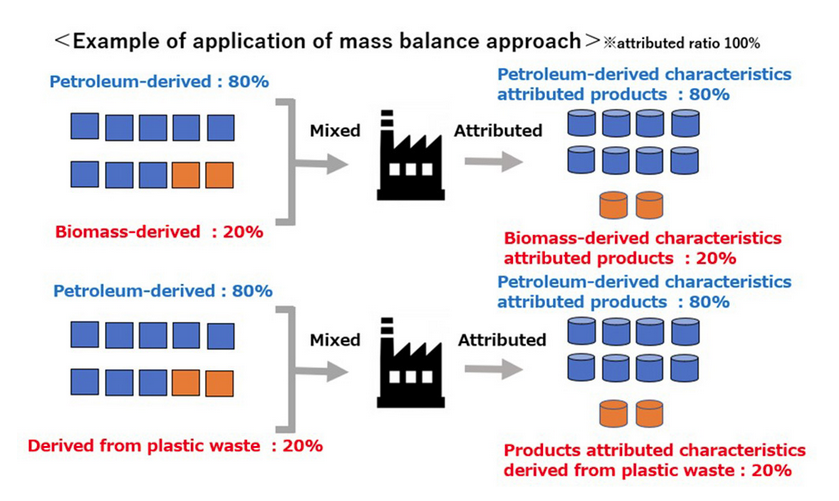

1. A mass balance approach is one by which raw materials with certain characteristics (an example being biomass-derived) are mixed with other raw materials (such as petroleum-derived ones) in the processing and distribution process, from raw materials through finished products. Characteristics are attributed to part of a product in line with input proportions of raw materials with those characteristics.

2. ISCC PLUS Certification is issued by the International Sustainability & Carbon Certification organization, focusing on such non-energy applications such as food, feed, chemicals, and bioplastics. The certification enables companies to demonstrate that they use sustainable raw materials and ensure transparency and traceability across their supply chains.

3. A life cycle assessment is a methodology for assessing environmental impacts associated all stages of product or service life cycles.

4. The Higg Index is a self-assessment tool that the Sustainable Apparel Coalition, now known as Cascale, launched in 2012 to evaluate sustainable product development and supply chain management, centered on environmental and social responsibility. This benchmark helps highlight environmental impacts and labor rights issues, encouraging companies to make their products and supply chains more sustainable. The apparel and fashion industries around the globe employ this tool.

Source

Toray, press release, 2025-03-11.

Supplier

International Sustainability & Carbon Certification (ISCC)

Toray Industries Inc.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals