Lignin and cellulose are polymers—large molecules made up of repeating modules—that are situated in a tangled braid, along with some other polymers, within the plant cell wall. Lignin and cellulose are the two main polymers and are key to the protective strength of plant cell walls. The components of lignin can be converted into valuable bioproducts. However, separating and deconstructing the lignin polymers in plant cell walls is difficult because they are interdependent with the other polymers, all of which are resistant to separation from one another. One approach, acidic pretreatment, can degrade and aggregate lignin, separating its components from the other polymers, but this form of lignin is useful most often for heat or power generation. Another approach is solvent pretreatment combined with genetic modification. This can alter plant cell wall structure and composition, ideally making the components more accessible to solvents that can help break down bonds in polymers. Researchers have now shown that some solvents are more effective than others at getting between plants’ polymers. This allows the polymers to be separated, under heat and acidic conditions, and the lignin to be partially deconstructed.

The Impact

Plant lignin, when isolated and depolymerized in strategic ways, can be used to make efficient biofuels and chemical building blocks to produce many economically important materials. Lignin is a polymer composed of different types of aromatic modules linked together in various ways. When lignin is deconstructed, its chemical modules can come apart in different sizes, bonds, and compositions. These modules have a range of potential uses as building blocks for biofuels and bioproducts. This research found that different solvents and different switchgrass genetic variations produce lignin extracts that are suited to specific applications.

Summary

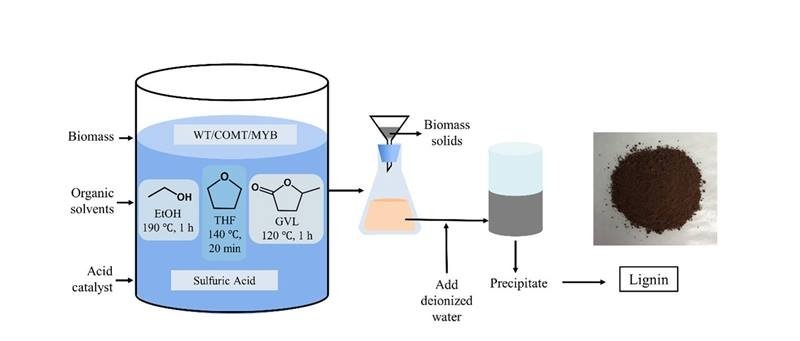

Researchers from the University of Tennessee, Knoxville and Oak Ridge National Laboratory used three pretreatment solvents to partially deconstruct and break away plant lignin from other cell wall components so the lignin modules can be extracted. The composition of the extracted lignin (and therefore its potential value) from wild type and genetic variants of switchgrass by each of the solvent conditions is reflected by its measurable molecular mass and remaining chemical bonds. Based on several types of analytical data, the researchers observed differences among the lignin extracts, indicating that various specific types of bioproducts can be generated from the lignin extract from each set of solvent and conditions. The molecular interactions among the solvents, cellulose, and lignin are key to the process. Characterizing those interactions for the set of pretreatment solvents was therefore another research goal. The researchers used computer simulations based on the analytical data to provide insight into the number of molecular interactions between the lignin and solvent molecules. The findings indicate that the ability to form those interactions is important for enabling lignin depolymerization.

The study showed that each of the three solvents and the switchgrass genetic variations are effective in generating lignin extracts of differing forms, suited for distinct uses. For example, the tetrahydrofuran pretreated lignin should be suitable for further depolymerization into monoaromatic compounds. The information from this study can aid in the selection of pretreatment based on the type of precursor modules needed for a particular use.

Source

DoE, press release, 2022-12-14.

Supplier

Knoxville’s Nonwovens Research

Oak Ridge National Laboratory

University of Tennessee

US Department of Energy (DoE)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals