We completed the printing phase of the TECLA supporting structure, the first and unique fully 3D printed construction based on natural materials and made with multiple 3D printers operating at the same time. The innovative habitat model engineered by WASP and designed by MC A – Mario Cucinella Architects took form, a new circular model of housing entirely created with reusable and recyclable materials, sourced from local soil, carbon-neutral and adaptable to any climate and context.

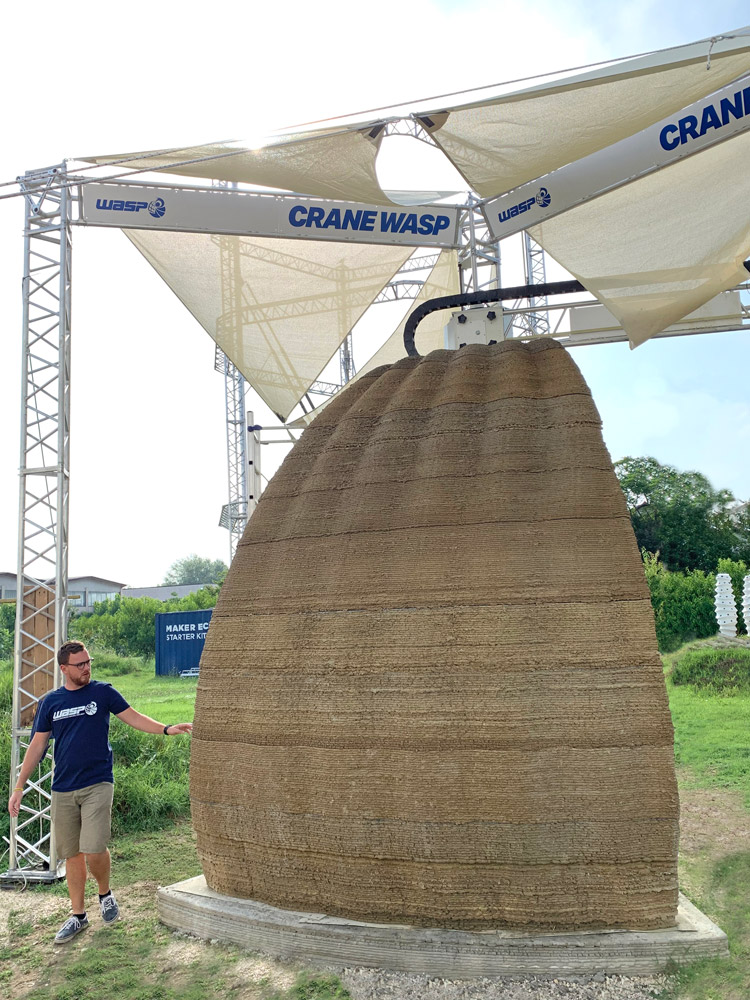

TECLA (which takes its name from Technology and Clay) was made in Massa Lombarda (Ravenna – Italy) with Crane WASP – WASP’s brand new 3D printer in the construction sector – it represented a real challenge for 3D printing, maximizing the performance of a material among the oldest and at the same time among the most stimulating for the future of the green economy: the raw earth.

TECLA is in fact the peak of advanced research between matter and technology, it is the achievement of an unparalleled challenge that has brought the printing geometry to its physical limit. The project represents an unprecedented perspective for buildings and new settlements, in which the value of local raw materials is amplified by digital design. The double dome solution made it possible to cover at the same time the roles of structure, roof and external cladding, making the house high-performance on all aspects.

“From the shapeless earth to the earth as house shaped. Today we have the knowledge to build with no impact in a simple click. – says Massimo Moretti, WASP Founder – Technology is now at the human service and the home as a birthright is real.”

“The completion of the structure is an important milestone and shows that, thanks to the design and technologies used, TECLA is no longer just a theoretical idea but can be a real and achievable response to the needs of living today and the future, that can be declined in different contexts and latitudes”, underlines Mario Cucinella, Founder of Mario Cucinella Architects and SOS – School of Sustainability.

Inspired by potter wasp, since 2012 WASP (World’s Advanced Saving Project) have been developing viable construction processes based on the principles of circular economy and digital fabrication. On the market since 2021, WASP produces 3D-printed houses in the shortest possible time and in the most sustainable way with the first multi-printer Crane WASP system, the company’s flagship of the construction line and the newco WASP On Site the company’s benchmark in architecture.

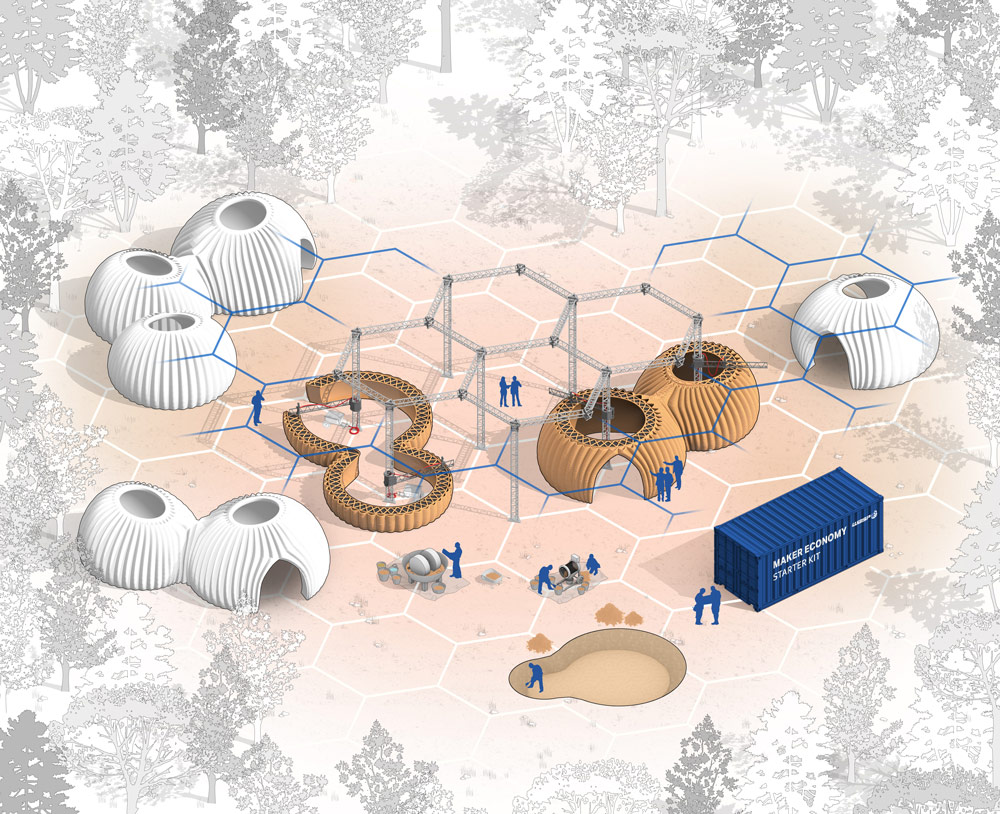

Crane WASP is the world’s first modular and multilevel 3D printer designed to collaboratively build singular and even more extensive architectural works.

The system is configured according to project needs and defines the structure of a safe and extremely efficient construction site. Each printer unit has a printing area of 50 square meters and therefore makes it possible to build independent living modules, of any shape, in a few days.

TECLA is the first eco-habitat built using, at the same time, multiple Crane WASP collaborative printers and it is the demonstration that 3D technology is able to create buildings by optimizing the construction process and minimizing the use of human and energy resources. The construction process can be replicated from time to time, thanks to the WASP Maker Economy Starter Kit, consisting of multiple 3D printers and a complex system of picking, mixing and pumping materials.

For the first time in the world, two printing arms have been synchronized as part of a construction, thanks to software capable of optimizing movements, avoiding collisions and ensuring simultaneous operation. The WASP proprietary software used for TECLA is the synthesis of years of research that have led to the computerization of shapeless matter, managing to build the imaginable.

TECLA can be synthesized in: 200 hours of printing, 7000 machine codes (G-code), 350 layers of 12 mm, 150 km of extrusion, 60 cubic meters of natural materials for an average consumption of less than 6 kW.

The final installation of TECLA and its presentation are scheduled for Spring 2021.

TECLA, a 3D printed global habitat for sustainable living

WASP and MC A – Mario Cucinella Architects have embarked on the construction of an innovative model for a 3D printed habitat and will be launching the first prototype near Bologna, Italy. Born from a vision to provide a home for everyone at a time of exponential population increase and an associated lack of affordable housing, TECLA is a new circular housing model, created using entirely reusable, recyclable materials taken from the local terrain. Built using Crane WASP – the latest innovation in on-site 3D construction, TECLA represents a step-change in the move towards eco-housing.

TECLA – 3d printed house

“WASP takes inspiration from the potter wasp. We build 3D printed houses using earth found on the spot, under a sustainable perspective. The oldest material and a state of the art technology merge to give new hope to the world. GAIA, our first 3D printed house made with raw earth, was born a year ago. Today with our partners we are printing TECLA an entire eco-sustainable habitat. The planet is asking for a joint project that we share with Mario Cucinella.” Massimo Moretti

“Together with WASP we aim at developing an innovative 3D-printed prototype for a habitat that responds to the increasingly urgent climate revolution and the needs of changes dictated by community needs. We need a paradigm shift in the field of architecture that gets closer to the needs of people, thus finding an answer for the “Earth” within the “earth”. A collaboration that becomes the union between empathic architecture and the application of new technologies.” Mario Cucinella

A United Nations report published in 2017 demonstrates that the current global population of 7.6 billion people is expected to reach 11.2 billion in 2100, and in 2030 nearly 5 billion people are expected to live in cities. Consequently, governments are faced with substantial challenges related to housing solutions. With more and more rural areas being incorporated into cities, it is the idea of city itself that must be challenged.

Designed by MC A and engineered and built by WASP

Taking inspiration from potter wasps, since 2012, WASP (World’s Advanced Saving Project) have been developing viable construction processes based on the principles of circular economy, that will create 3D printed houses in the shortest period of time, and in the most sustainable way possible.

TECLA will be the first habitat to be built using multiple collaborative 3D printers, offering a greater scope of scale than ever before.

Used in the context of a wider masterplan, TECLA has the potential to become the basis for brand new autonomous eco-cities that are off the current grid.

TECLA will be the first house to be entirely 3D printed using locally sourced clay

A biodegradable and recyclable ‘km 0 natural’ material which will effectively make the building zero-waste.

It will be built to adapt to multiple environments, and it will be suitable for self-production through the use of WASP’s innovative Maker Economy Starter Kit.

This approach will limit industrial waste and offer a unique sustainable model that will boost the national and local economy, improving the wellbeing of communities.

Furthermore, the scheme will significantly accelerate the construction process as the 3D printer will produce the entire structure at once.

TECLA was developed using in-depth research undertaken by the SOS – School of Sustainability

A professional school founded by Mario Cucinella that combines education, research and practice.

The research, conducted with the support of MA students from the Sustainable Environmental Design programme at the Architectural Association School of Architecture in London, explored the cause and effects of homelessness.

It interrogated the use of technological advances to enable a solution, based on case studies in locations with different climates.

The result is a highly flexible envelope, designed to be resilient to any climate and energy-efficient in a way that traditional housing models are not.

Partners and technology

The collaboration between MC A and WASP has been supported by Mapei, a worldwide producer of construction materials, which has studied the clay materials and identified the key components within the raw earth mixture to create the final highly optimised printable product. Structural tests were carried out by Milan Ingegneria, a Milan-based engineering consultancy, which worked on the optimisation of the shape in order to create a self-supporting structure. The frames, customised and highly-efficient, have been engineered and produced by Capoferri, a company specialised in architectural frames and always at the forefront of technological advances, while the landscaping has been curated by Frassinago, a multidsciplinary company that includes a design studio that deals with landscape architecture, and a firm specialized in the gardening and outdoor sector. RiceHouse provided technical consultancy about bio-materials deriving from rice cultivation waste, which affected the thermal performance and living comfort of the building envelope. The lighting project, developed both internally and externally with the aim of achieving the maximum flexibility and sustainability of the intervention, has been developed by Lucifero’s.

TECLA received planning approval in May 2019, commenced printing in September 2019. The final installation and its presentation are scheduled for Spring 2021.

A project by WASP & Mario Cucinella Architects

WASP Engineering and 3D printing construction

Mario Cucinella Architects Architectural design and management

In collaboration with:

SOS – School of Sustainability Research partner

Mapei Materials consultancy and supply

Milan Ingegneria Structural consultancy

Capoferri Frames engineering and production

RiceHouse Bio-materials consultancy and supply

Frassinago Landscaping

Lucifero’s Lighting design

Imola Legno: Timber solutions consultancy and supply

Primat • Terracruda®: Earthen floor supply

Cefla: Electrical solutions supply

Under the patronage of: Municipality of Massa Lombarda

Sponsored by: Ter Costruzioni

Source

WASP, press release, 2021-01-26.

Supplier

Mapei

Mario Cucinella Architects

RiceHouse Bio-materials consultancy and supply

SOS – School of Sustainability

WASP

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals