- Plant operation launched in Stralsund (Germany) for converting renewable electricity into bio methanol.

- The plant will be operated in a long-term test over one year achieving a maximum capacity of 28 liters crude methanol per day.

- High interest from industry, associations and politics

The group of BSE and the Institute for Renewable Energy Systems at Stralsund University of Applied Sciences (IRES) were able to convert wind power into renewable methanol (bio methanol) for the first time. Operation of this technology under dynamic conditions will be confirmed during a long-term test over one year.

The group of BSE and the Institute for Renewable Energy Systems at Stralsund University of Applied Sciences (IRES) were able to convert wind power into renewable methanol (bio methanol) for the first time. Operation of this technology under dynamic conditions will be confirmed during a long-term test over one year.

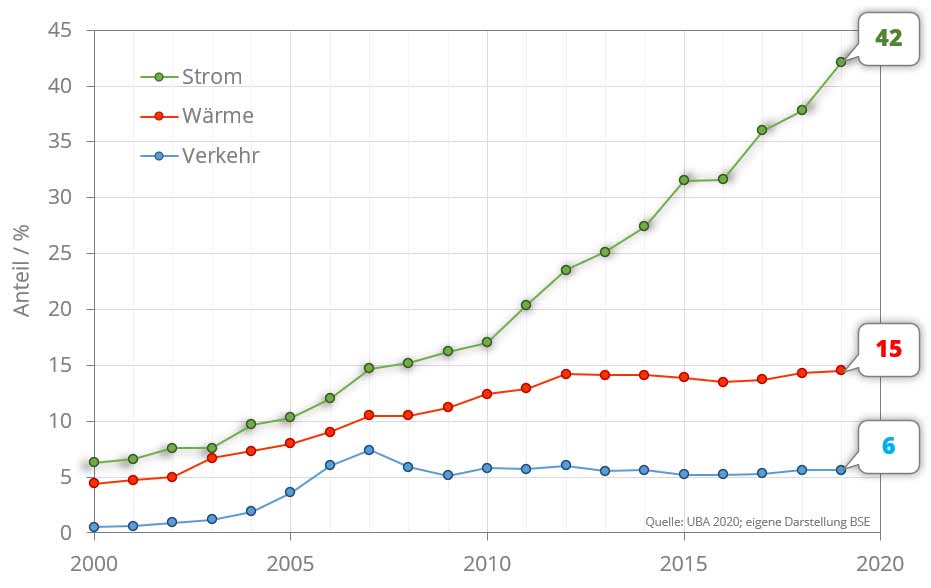

In the course of the energy transition, the proportion of renewable energy sources in the field of electricity consumption is continuously increasing and accounts currently 42 % in Germany. In order to effectively reduce the use of fossil fuels such as oil, natural gas and coal, renewable energies must also be used for heating and transport. The proportion here is only 15 and 6 %, respectively. This so-called sector coupling has now been achieved by BSE and IRES.

The team uses green electricity to split water into hydrogen and oxygen in an electrolysis step. The hydrogen is then converted to the valuable product methanol using a suitable carbon dioxide source in a specially developed process (so-called FlexMethanol). On the one hand side, methanol represents a crucial base chemical. On the other hand, methanol can be used as a fuel. Beside direct combustion in engines, the chemical processing of methanol into fuel substitutes and additives such as MTBE, DME and bio diesel is also possible. Christian Schweitzer, managing director of BSE:

„In the future, the fuel cell suitable crude methanol as well as the cleaned methanol will be sold industrially as e-fuel. The special feature of FlexMethanol systems from BSE is the mode of operation that is adapted to the electricity supply starting from CO2 separation, alkaline electrolysis up to distillation.” (Christian Schweitzer, bse Engineering, Managing Director)

The dynamic operation is of central importance for the conversion of green electricity from volatile energy sources to flexibly react to the fluctuating energy supply. Moreover, photovoltaic and wind power plants do not have to be reduced during periods of electricity surplus, but can be used for the chemical utilization of electricity. Prof. Dr. Johannes Gulden, Director of IRES, stated:

„Based on the reduced wind power in 2016 in Mecklenburg-Vorpommern, up to 34,800 t of methanol could have been produced.“ (Prof. Dr. Johannes Gulden, FH Stralsund, Director of IRES)

The facility in Stralsund is equipped with a tube bundle reactor for the chemical synthesis at 240°C and 40 bar using recycle loop of the non-converted synthesis gas. A maximum capacity of 28 liters crude methanol per day is achieved. As a result, the first samples of methanol have now been produced from electricity. Beside continuous evaluation of relevant parameter such as temperature, pressure and hydrogen as well as carbon dioxide stream, the amount and composition of gas phase and liquid products is systematically investigated. The first analysis approves high purity of the produced crude methanol. The compliance of international IMPCA specifications after distillation is therefore ensured.

Within the ongoing investigations, different fluctuating and dynamic scenarios are confirmed and optimized. “Thus, experiences from the tests are directly implemented in the first plants leading to an increase of the economic efficiency.”, as Christian Schweitzer stated. Meanwhile, the development of these plants is fully under way, while realization is expected within this year. The finale results of the project with IRES will be available in line with the commissioning of the plants.

The companies Aker Solutions and Sulzer Chemtech cooperate with BSE in the upstream process step of CO2 separation and respectively the subsequent purification to the international methanol standard (IMPCA) with a purity of 99.85 Vol.-%.

About bse Engineering

According to the motto “More Solutions – Less Buildings,” BSE maximize their customers’ benefit through individually aligned organizational, logistical, economical, normative and – not only – construction measures. We go for a long-term partnership as factory planner with our customers. And through the cooperation with freelancers and business partners we are able to adjust our skills and capacities to meet our customers’ requirements. BSE focusses on researching, developing and realizing plants in the field of resource-saving, renewable and biogenic energy generation.

About IRES

The Institute for Renewable Energy Systems organizes the joint efforts of the University of Applied Sciences

Stralsund concerning applied research as well as practical teaching in the fields of utilization of renewable energy sources and hydrogen technology. The scientific work of the institute aims interdisciplinary research, teaching, education as well as technological transfer in the field of modern energy systems with the following focuses: utilization of renewable and alternative energies, energy conversion/storage/usage, modeling and automation of related processes and economic as well as environmental issues.

Source

bse Engineering, press release, 2020-06-09.

Supplier

Aker Solutions

bse engineering Leipzig GmbH

Hochschule Stralsund

Institut für Regenerative EnergieSysteme IRES

Sulzer Chemtech Ltd.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals