Kalix high-performance polyamides (HPPAs) are used to make structural components for electronic devices, replacing commodity plastics in parts such as covers and housings. This is a compound, comprising polymers combined with fillers and additives, which has been available for over a decade.

It’s a highly demanded material, as it delivers exceptional strength, stiffness and better chemical resistance compared to traditional polycarbonates.

It’s also easier to work with than other plastics, because it requires slightly lower temperatures to process and was specifically formulated so that its flow can be better controlled during molding, facilitating the manufacturing of thin yet robust structural parts for electronic devices. “That was the starting point for developing Kalix,” explains Thomas Kohnert, its product manager. “Then we further modified and enhanced the product portfolio.”

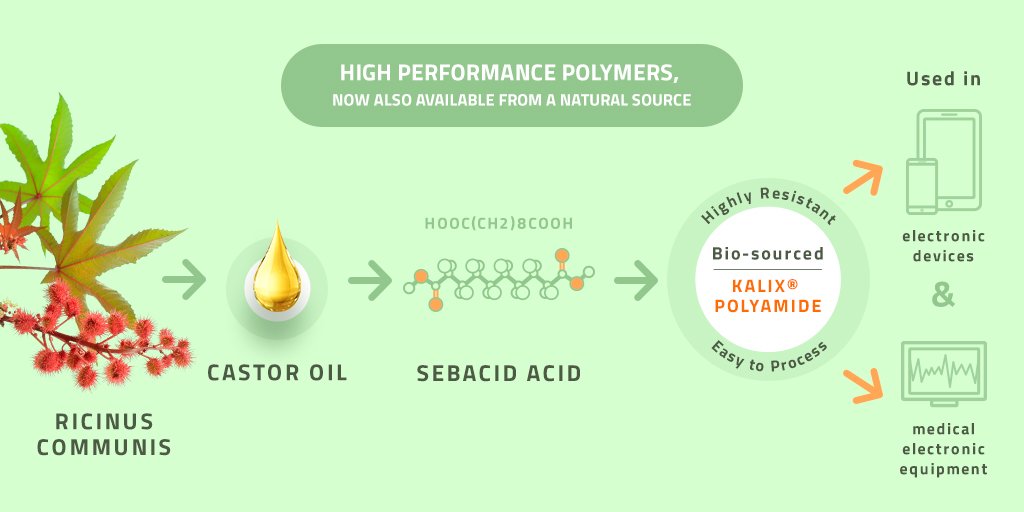

Since 2013, one particular series within this family, the Kalix 2000, has been partially bio-sourced, but now a new series, Kalix 1000, has been launched on the market, made from a 100% natural and sustainable raw material: castor oil.

The underlying reason for this evolution was the increasing pressure from consumers on device manufacturers to come up with more sustainable solutions. A request that was in turn transmitted to Solvay. “We were getting requests for a polyamide-based product that would be derived from sustainable sources,” says Thomas. And now that it’s here, this much more eco-friendly solution isn’t likely to be going anywhere. “This bio-sourced series will probably become the main Kalix in the future. Developing it was a big effort; there were lots of roadblocks, such as establishing the supply chain and tailoring the new products to meet customer needs, but it was major demand from the market, so we had to address that.”

Robust enough for hospitals

Meanwhile, the Kalix family is also conquering new markets. In 2017, Kalix 5950 was launched for the medical electronic equipment segment. “More and more electronic devices are used in healthcare, so it makes sense to use a material from the consumer electronics market and apply it to the healthcare space,” explains Jeff Hrivnak, Healthcare Global Business Manager at Solvay Specialty Polymers. “Hospitals need to clean their equipment thoroughly several times a day to fight hospital-acquired infections, so they’re looking for materials that can resist aggressive disinfectants. Current materials like polycarbonate need to be upgraded, and that’s where Kalix comes in.”

Success has been immediate, with all the major medical electronic equipment manufacturers worldwide showing interest for this highly resistant material that also offers the advantage of being reasonably priced and compatible with existing tooling. “This is a major new opportunity to diversify the markets for this family of products,” says Thomas. “We wanted to fill the gap between medical grade and general polymers.”

For the time being, the bio-sourced series isn’t in use here, as the healthcare industry’s top priorities are currently performance, safety and reliability – “but in the future this might represent a nice value proposition,” says Anna Maria Bertasa, Healthcare Global Market Manager at Specialty Polymers. Especially considering the rapid expansion of Kalix in the healthcare segment. “Our starting point was healthcare electronics, but now its applications are expanding to other types of equipment – basically any surface that needs to be disinfected. The market has high expectations for this material, which is perceived as cutting edge.”

Source

Bioplastics MAGAZINE, 2018-09-25.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals