At the DEEP PURPLE demo sites, we annually convert 438,000 cubic meters of domestic wastewater and 164 tons of organic fraction of municipal solid waste (OFMSW) into raw materials. These raw materials include 260 tons of enriched biomass feedstock, 16 tons of cellulosic material, and 5 tons of biogas. Our project endeavors to showcase the feasibility of transforming these materials into five ‘consumer’ products that boast better overall sustainability scores compared to existing alternatives, ensuring proper technical performance and addressing clear market demand.

One such product is self-repairing composites formulated with cellulose fiber and PHA polymers. The presence of cracks in concrete is nearly unavoidable, leading to irreparable damage due to water-borne contaminants or aggressive compounds penetrating the concrete matrix through fissures and cracks. This damage necessitates costly repairs globally. While extensive research on self-healing materials has been conducted, many available techniques are expensive, chemical-based, and require human intervention.

Microbially induced calcium carbonate (MICP) via urea hydrolysis has emerged as a promising pathway for a wide range of engineering applications. Bacterial cells/spores, along with mineral precursors, are embedded directly into the concrete matrix during mixing. Upon crack formation, bacterial cells/spores activate in the presence of moisture and oxygen, leading to CaCO3 by-product production through bacterial metabolic processes and crack sealing.

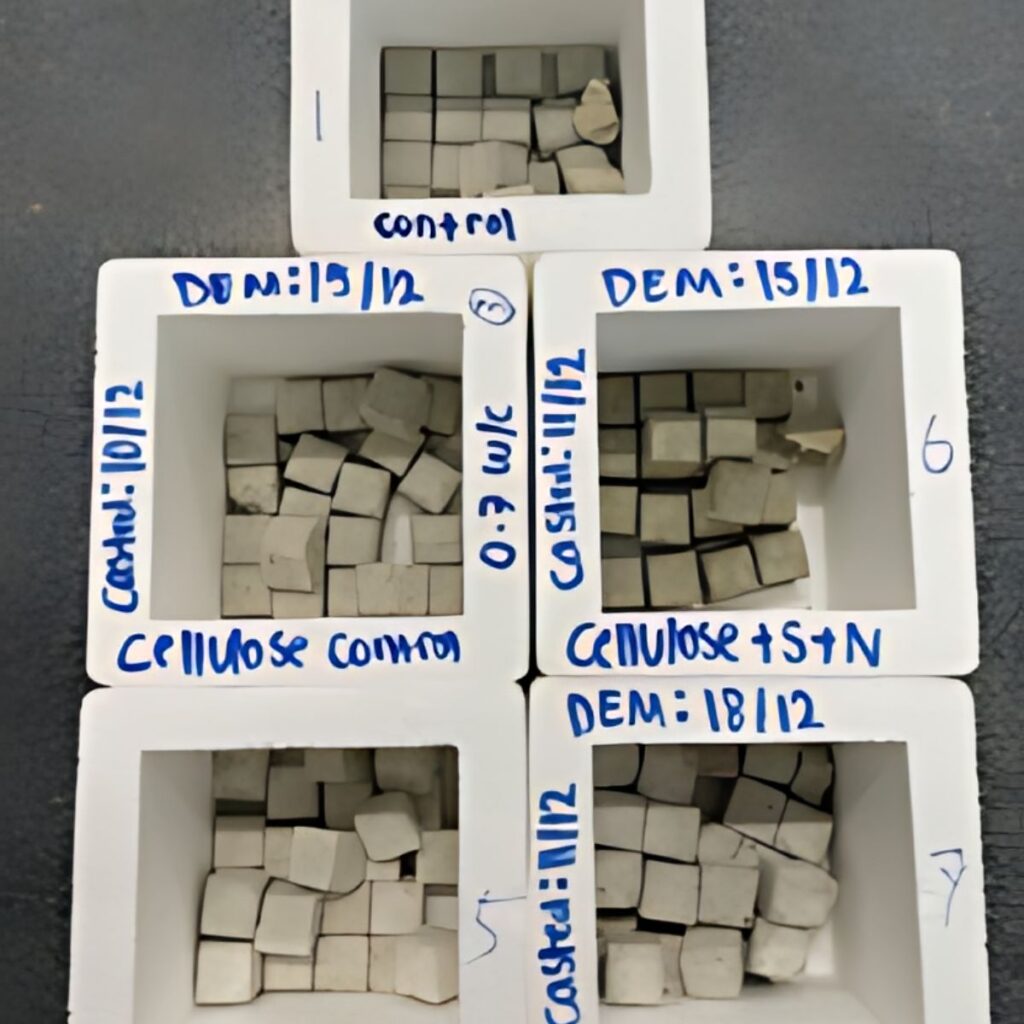

Innovative, cost-effective, and sustainable encapsulation methods based on nanocellulose and PHA bioplastics have been developed by University of Brunel within the DEEP PURPLE project. This development has resulted in self-healing materials. The proposed solution utilizes a three-component healing system comprising polymeric material (cellulose and PHA bioplastics) impregnated with bacterial spores and mineral precursors. Upon crack formation, the polymeric capsule ruptures, facilitating oxygen penetration through cracks and fissures. Encapsulated spores activate and germinate, feeding on mineral precursors to produce calcium precipitation, ultimately sealing cracks within concrete structures

The University of Brunel has an extensive experience in validating and standardizing processes for the development of microcapsules used in self-repairing construction materials. They have developed self-repairing biocomposites by incorporating previously developed CNF and PHA, along with microcapsules prepared by Brunel. The performance of these self-repairing biocomposites was tested under various conditions such as temperature, pressure, humidity, light, and vacuum to ensure both long-term durability and high healing performance throughout their service life.

Source

Deep Purple, press release, 2024-02-26.

Supplier

Brunel University London

Deep Purple

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals