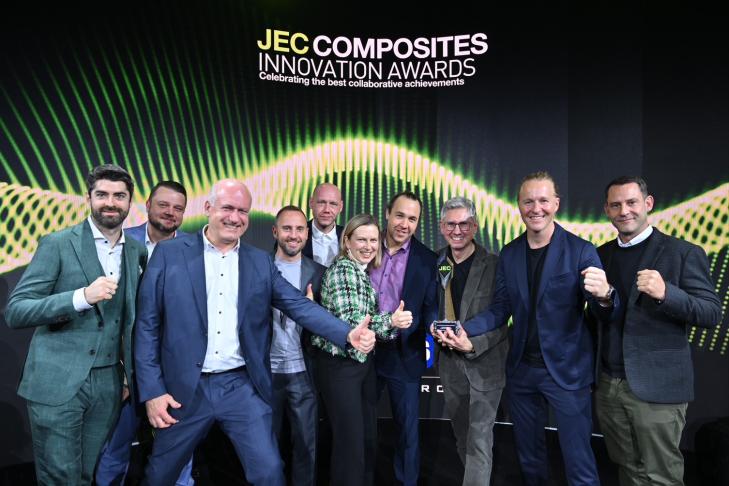

Following the major announcement in June 2025 with the extensive use of our ampliTex™ in exteriors and interiors of BMW Group series production road cars, Bcomp and BMW Group’s joint collaboration “BMW M NATURAL FIBRE COMPOSITES” has won first prize in the category “Automotive & Road Transportation – Parts” at the 2026 JEC Composites Innovation Awards, the world’s most prestigious composites show and award.

This award recognises the most innovative composite solutions worldwide. Since 1998, the JEC Composites Innovation Awards have attracted more than 2,200 participating companies, with 269 companies and 811 partners honoured for excellence in innovation. This recognition is a testament to the successful validation and industrialisation of natural flax fibre composites for visual exterior applications of series premium performance road cars, representing a fully scaled real-world application of high-performance natural fibre composites in the automotive industry to date.

BMW M Motorsport first introduced renewable reinforcements in 2019 through its Formula E programme, using Bcomp’s ampliTex™ and powerRibs™. Building on these racetrack learnings, BMW Group and Bcomp have researched, validated and industrialised natural fibre composites for series production — a true race-to-road success story.

Bcomp and BMW Group tackled one of the industry’s biggest engineering challenges, passing ageing, quality, and capacity requirements of large-scale exterior automotive parts with natural fibres. After multiple years of joint development, Bcomp’s technologies make it possible to replace parts traditionally made with carbon fibre for the past few decades. One example: Exchanging carbon fibre composites for Bcomp’s high-performance natural fibre composites in the roof of the next-generation BMW series production cars leads to a CO₂e reduction of around 40% in production plus additional end-of-life considerations.

To make natural fibre composites viable for automotive parts, Bcomp engineered automotive-grade, high-performance natural fibre roving in-house, designed specifically to replace carbon fibre in large-scale exterior and interior automotive applications. Working with BMW Group’s design team, Bcomp created a bespoke colour and weave pattern to create a distinctive natural fibre identity aligned with BMW Group’s brand aesthetic. The team tested more than 100 material iterations until a solution was found that was robust enough to pass all automotive exterior requirements.

Scalability and industrial integration into existing production processes are also a crucial part of the innovation. To meet large scale demand and BMW Group’s exacting production standards, Bcomp built a new manufacturing facility. This facility and its already planned expansion will ensure manufacturers have access to a reliable, scalable supply chain for sustainable composites.

The materials are designed to integrate seamlessly into multiple and existing manufacturing processes at scale. For instance, the roof will be made using a fully automated RTM process, which makes production fast and consistent.

Christian Fischer, CEO and Co-founder at Bcomp, said: “After years of development and rigorous validation, ampliTex™ natural fibre composites are now integrated into BMW’s series manufacturing lines for both exterior and interior applications. This milestone marks the largest real-world application of high-performance renewable composites in the automotive industry; it demonstrates that natural fibre composites are ready for large-scale premium automotive applications.”

Source

Bioplastics MAGAZINE, 2026-01-19.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals