Polylactic acid, also known as PLA, is a thermoplastic monomer. It is derived from renewable, organic sources such as corn starch or sugar cane. This means that PLA is different from most plastics. It will not fall apart into persistent microplastics, but fully degrade in the presence of water (hydrolysis). As more microplastics become a persistent problem at the end of their life, this is a promising way out.

These are the findings by Hydra Marine Sciences, in a study commissioned by Holland Bioplastics – an association advancing bioplastics knowledge worldwide. Polylactic acid s a biobased polymer made entirely from fermented plant sugars. The study shows that in an aqueous environment, PLA will hydrolyse into molecules of ever-smaller size (hydrolysis).

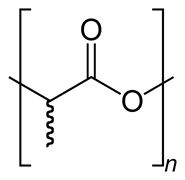

Lactic acid

Hydrolysis is an abiotic process that occurs in the presence of moisture or humidity. In such conditions, Polylactic acid will fall apart into smaller fragments. The rate at which this occurs is determined by temperature. Eventually the polymer chains are so short that the material becomes soluble in water. There it will subsequently be biodegraded by microorganisms into biomass, water, and carbon dioxide. In other words: no toxic substances will result from these processes.

Lactic acid, the monomer building block of PLA, is classified as safe and non-toxic both in the US and the EU. The same holds true for many PLA grades in food contact requirements. Additionally, specific grades of polylactic acid have been approved and used for decades in medical applications like sutures and tissue scaffolds. Such substances are safely absorbed and bioassimilated by the human body after use. We now use it to make a wide range of products: cups, cutlery, bin liners, flexible food packaging. In other words, PLA seems fit for overcoming at least part of the microplastics problem.

Microplastics, an underestimated problem

Microplastics form a problem underestimated by industry. In this area, consumer sentiment may be well ahead of industrial policy. Lux Research’s Anthony Schiavo warns for a backlash. He is of the opinion that ‘companies need to be proactive about consumer sentiment by identifying and formulating out the worst sources of microplastics and engaging directly with microplastic cleanup efforts and technology, before the backlash really starts.’

Others agree. Erwin Vink, Board Member of Holland Bioplastics, says that we need to choose more responsible materials for the products we rely on, on the one hand; and on the other hand develop a better plastic collection and waste processing infrastructure. Polylactic acid will be part of that solution, as it will not have the long-term effects of present micro- and nanoplastics, the end phase of non-biodegradable substances. Even though, also with PLA, we should avoid littering the environment with it.

Biodegradable plastics

Fortunately, there are more biodegradable plastics like polylactic acid. There are polyhydroxyalkanoates (PHAs), starch blends, cellulose-based plastics and lignin-based polymer composites. PLA stands out because it is not just environmentally benign, it is also a cheap and very versatile plastic. And it has a low carbon footprint. We produce lactic acid from plant sugars by fermentation. This is then polymerized into the polylactide biopolymer, PLA.

Polylactic acid, says Wikipedia, has become a popular material due to it being economically produced from renewable resources. In 2021, PLA had the highest consumption volume of any bioplastic of the world. PLA is the most widely used plastic filament material in 3D printing, due to its low melting point, high strength, low thermal expansion, and good layer adhesion. It has many properties that may propel it to the most widely used plastic in the world.

Author

Diederik van der Hoeven

Source

Supplier

Holland Bioplastics

Hydra Marine Sciences GmbH

Lux Research, Inc.

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals