There is a good reason why plastic pollution has become such a burning issue. More than 98 % of plastics are currently produced from non-renewable sources, and even those that are biobased are not all recyclable or biodegradable. This has led to waste management problems and serious environmental repercussions, especially due to the use of two culprits commonly used in plastic packaging: polyethylene (PE) and polyethylene terephthalate (PET).

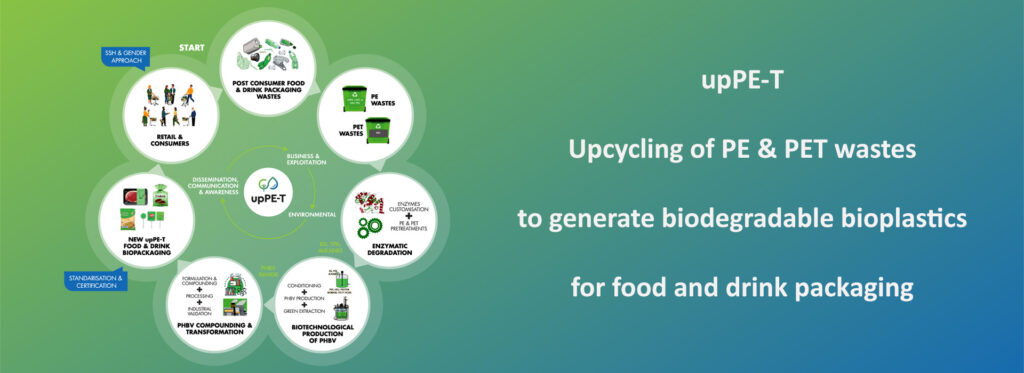

Since its launch in 2020, the EU-funded upPE-T project has sought to overcome this challenge by turning PE and PET packaging waste into a bioplastic that can be used for biodegradable packaging. As reported in a recent article posted on the ‘Innovation News Network’ website, upPE-T has created a value chain for upcycling plastic packaging waste.

The value chain follows circular economy criteria. It involves “biotechnological processes connected in a closed loop, from waste to high-value product, with zero waste and using secondary raw materials.” upPE-T’s upcycling process entails two steps, polymer waste pretreatment and enzyme engineering. Some project partners have been developing pretreatments aimed at making PE and PET waste more susceptible to attack by enzymes. Other partners have been looking for novel enzymes that are better catalysts and more thermally stable in order to improve on the performance of enzymes currently in use.

Optimising and scaling up

“The different new enzyme variants have been cloned, produced, purified, and subsequently tested at a lab scale to evaluate their degradation activity,” reports the article. “Synergy and cascade degradation using several enzymes has been shown to be the best strategy to reach the efficiency targets for the polymer degradation processes.”

A German partner is working on bringing the enzymatic upcycling process closer to an industrial scale. An important part of this scaling up step is the recovery of by-products, the final goal being 100% water recirculation and enzyme recovery. This will help reduce costs and the overall environmental impact. The products resulting from the enzymatic degradation of PE and PET will be converted into secondary raw materials used in the production and green extraction of poly(3-hydroxybutyrate-co-3-hydroxyvalerate), a polymer commonly known as PHBV.

“We are currently scaling up the fermentation process for making the PHBV powder,” the article reports. Spanish project teams are developing a cell factory for the production of PHBV from industrial waste and secondary raw materials using halophilic microorganisms called Haloferax mediterranei.

“Two different types of waste have been tested as a carbon and nitrogen source for the production of PHBV by Haloferax mediterranei, the biomass obtained in the bioconversion of TPA (PET waste degradation product) and sugar-rich waste from the candy industry.”

Partners are also focusing on developing biodegradable formulations with the PHBV produced in the upPE-T cell factory. The material’s advantages over other biodegradable polymers are that it is not synthetic and is also biodegradable in soil, fresh water and sea water. Other tasks include studying how adding PHBV to other biodegradable plastics affects their mechanical properties and biodegradation, and improving the barrier properties of biodegradable plastics using nanotechnology. Several partners are also dedicated to evaluating the environmental impact of the processes developed under upPE-T (Upcycling of PE and PET wastes to generate biodegradable bioplastics for food and drink packaging). The project ends in October 2024.

Source

CORDIS, press release, 2023-12-04.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals