The University of Northern Iowa’s National Ag-Based Lubricants (NABL) Center has developed a technology that continuously recycles engine oil, overcoming the problem of oxidation stability and allowing biobased engine oil to be used in diesel engines.

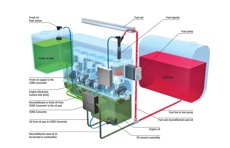

Image of the CORS Converter. For printing Image of the CORS Converter. For printing quality see below at further information. Image: University of Northern Iowa. |

Continuous Oil Recycling System (CORS) in essence is like an on-board biodiesel manufacturing plant that removes small quantities of biobased engine oil from the crankcase, cleans and modifies it, and then feeds the oil into the engine fuel lines.

“We thought rather than forcing vegetable-based oil to last in an engine for 10,000 to 15,000 miles, we would change the oil before it breaks down and replace it with fresh oil,” said UNI-NABL Center Director Lou Honary. “If soybean oil or other vegetable oil can safely perform for, say, 50 hours or 2,500 miles, the computerized recycling system would ensure the oil is consumed as diesel fuel before the 50 hours of performance.”

Sensors on CORS continuously monitor the physio-chemical properties of the oil and replace old oil with new at precisely the right time by feeding it into the fuel line in very small quantities. All that is needed is a small reservoir to store a fresh supply of oil.

“The CORS concept offers an opportunity for the earlier adoption of engine biolubricants,” said Bill Mitchell, a retired agricultural machinery engineer who serves as a consultant on this project. “Features of the biobased engine lubricants in the CORS concept offer extraordinary natural lubricity, reduced petroleum dependency and waste-oil elimination.”

The amount of fresh oil used is as high as one-twentieth the amount of fuel used in the diesel engine. The on-board CORS computer processor constantly “communicates” with engine electronics to ensure optimum timing for burning small quantities of the engine oil. Using a 2-percent mixture of oil into diesel fuel for most stationary engines would provide all the benefits of biodiesel and result in an automatic oil change as desired. This technology eliminates the need for an actual oil change, but does require an infrequent change of the oil filter.

CORS has been successfully tested in the laboratory and is now entering the field test stage. First target engines are in utility companies’ stationary diesel engines, and will then be tested in hospitals and other facilities that rely on their own electricity generated by diesel engines. Ships, shipyards and other areas storing large volumes of fuels also will be tested.

Current tests use a special high oleic version of soybean oil, but research shows that other vegetable oils should work as well because “the sensors are blind to the type of oil being used,” according to Honary.

“CORS is a smart technology that reacts to the variables in the motor oil and the engine,” he said. “At the early stages of introduction, the CORS technology is suited for larger, stationary engines. The later versions will investigate use in off-highway construction and agricultural equipment, and eventually in on-road trucks and passenger cars.”

UNI’s NABL Center is a non-profit, university-based research and testing facility dedicated to the advancement of biobased lubricants. The center was established in 1991 through the collaborative efforts of UNI, the state of Iowa, the U.S. Department of Energy, the U.S. Department of Agriculture, and the Iowa Soybean Association/Iowa Soybean Promotion Board. The NABL Center has commercialized more than 30 soybean-oil-based industrial lubricants and greases.

Further information

Image of the Continuous Oil Recycling System (CORS) Converter (PDF document, 3.2 MB)

Homegrown engine oil. (PDF document) Cover story on CORS in: OEM Off-Highway magazine, May 2009, p. 10-13.

Contact

University of Northern Iowa

National Ag-Based Lubricants Center

Lou Honary (director)

Tel.: 001-319-352-52 18

E-Mail: lou.honary@uni.edu

Internet: www.uni.edu/nabl

Source

University of Northern Iowa, press release, 2009-06-03.

Supplier

University of Northern Iowa (UNI)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals