Studies have shown that Zophobas atratus worms (the larvae of the darkling beetle commonly sold as pet food and known as ‘super worms’ for their nutritional value) can survive on a diet of plastic because their gut contains bacteria capable of breaking down the common type of plastic. However, this would be considered impractical plastic processing due to the slow rate of feeding and worm maintenance.

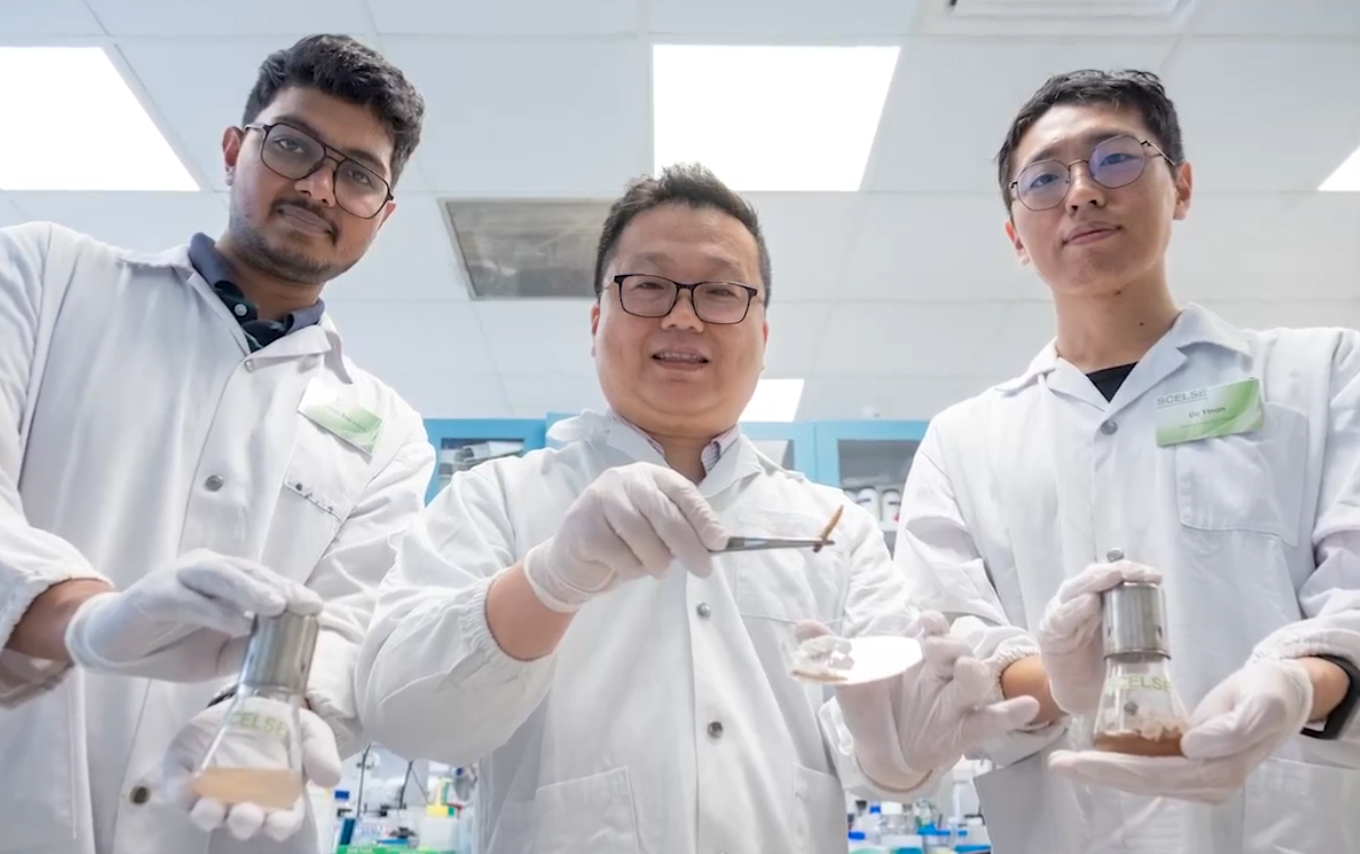

A team of scientists from NTU’s School of Civil and Environmental Engineering (CEE) and Singapore Centre for Environmental Life Sciences Engineering (SCELSE) offered hope for a nature-inspired method to tackle the global plastic pollution problem. They have developed an artificial ‘worm gut’ that breaks down plastics which accelerates plastic biodegradation.

NTU Associate Professor Cao Bin at the School of CEE and Principal Investigator at SCELSE said, “A single worm can only consume about a couple of milligrams of plastic in its lifetime, so imagine the number of worms that would be needed if we were to rely on them to process our plastic waste. Our method eliminates this need by removing the worm from the equation. We focus on boosting the useful microbes in the worm gut and building an artificial ‘worm gut’ that can efficiently break down plastics.”

To create the plastic-digesting worm gut, the scientists fed three groups of super worms different plastic diets – High-density polyethylene (HDPE), Polypropylene (PP) and Polystyrene (PS) – over 30 days. The control group was fed a diet of oatmeal. These plastics are selected as they are among the most common plastics used in everyday items like food boxes and detergent bottles. HDPE is a type of plastic known for its high-impact resistance, making it difficult to break down.

After feeding the worms plastic, scientists extracted the microbiomes from their gut and incubated them in flasks containing synthetic nutrients and different types of plastics, forming an artificial ‘worm gut’. Over six weeks, the microbiomes were left to grow in the flasks at room temperature.

The scientists found that compared to the control group, the flasks that contained the gut microbiomes from the plastic-fed worms showed a significant increase in plastic-degrading bacteria.

Furthermore, the microbial communities colonizing the plastics in the flasks were simpler and more tailored to the specific type of plastic than the microbes found on plastics that had been fed directly to the worms. When the microbial communities are simpler and targeted to a specific type of plastic, this translates to potential for more efficient plastic degradation when used in real-life applications.

First author of the study Dr Liu Yinan, Research Fellow at the School of CEE and SCELSE, said, “Our study represents the first reported successful attempt to develop plastic-associated bacterial communities from gut microbiomes of plastic-fed worms. Through exposing the gut microbiomes to specific conditions, we were able to boost the abundance of plastic-degrading bacteria present in our artificial ‘worm gut,’ suggesting that our method is stable and replicable at scale.”

The scientists say their proof-of-concept lays the foundation for developing biotechnological approaches that use worms’ gut microbiomes to process plastic waste.

For their next steps, the scientists want to understand how the bacteria in the superworm’s gut break down the plastics at the molecular level. Understanding the mechanism will help scientists engineer plastic-degrading bacterial communities to break down plastics efficiently in the future.

Source

NTU, press release, 2024-02-14.

Supplier

Nanyang Technological University (Singapore)

NTU's School of Civil and Environmental Engineering (CEE)

Singapore Centre for Environmental Life Sciences Engineering (SCELSE)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals