Deutsche Version: https://renewable-carbon.eu/news/nova-papier-8-publiziert

Experts from nova-Institute, industry and several European Universities developed a new approach to support policy and investment decisions on which feedstock – process – product combination to choose. The Biomass Utilization Efficiency (BUE) analysis is a quick and easy metric, which answers two important questions regarding the bioeconomy and bio-based chemicals: How efficiently is biomass utilized? What share of biomass ends up in the final product? www.bio-based.eu/nova-papers

The prominent role of the Biomass Utilization Efficiency (BUE) in the context of existing methods is evident. This new metric emphasizes the best combination of biomass feedstock, process and bio-based product, which is absent from existing calculations routinely used by research, process chemists and engineers. At present, waste minimization during a manufacturing process is addressed through the choice of methods and optimization of conditions. However, a BUE analysis makes clear that inherent waste, caused by inefficient feedstock – process – product choice, produced by aerobic fermentation for example, is easily overlooked when it concerns the conversion of biomass into chemical intermediates or fuels.

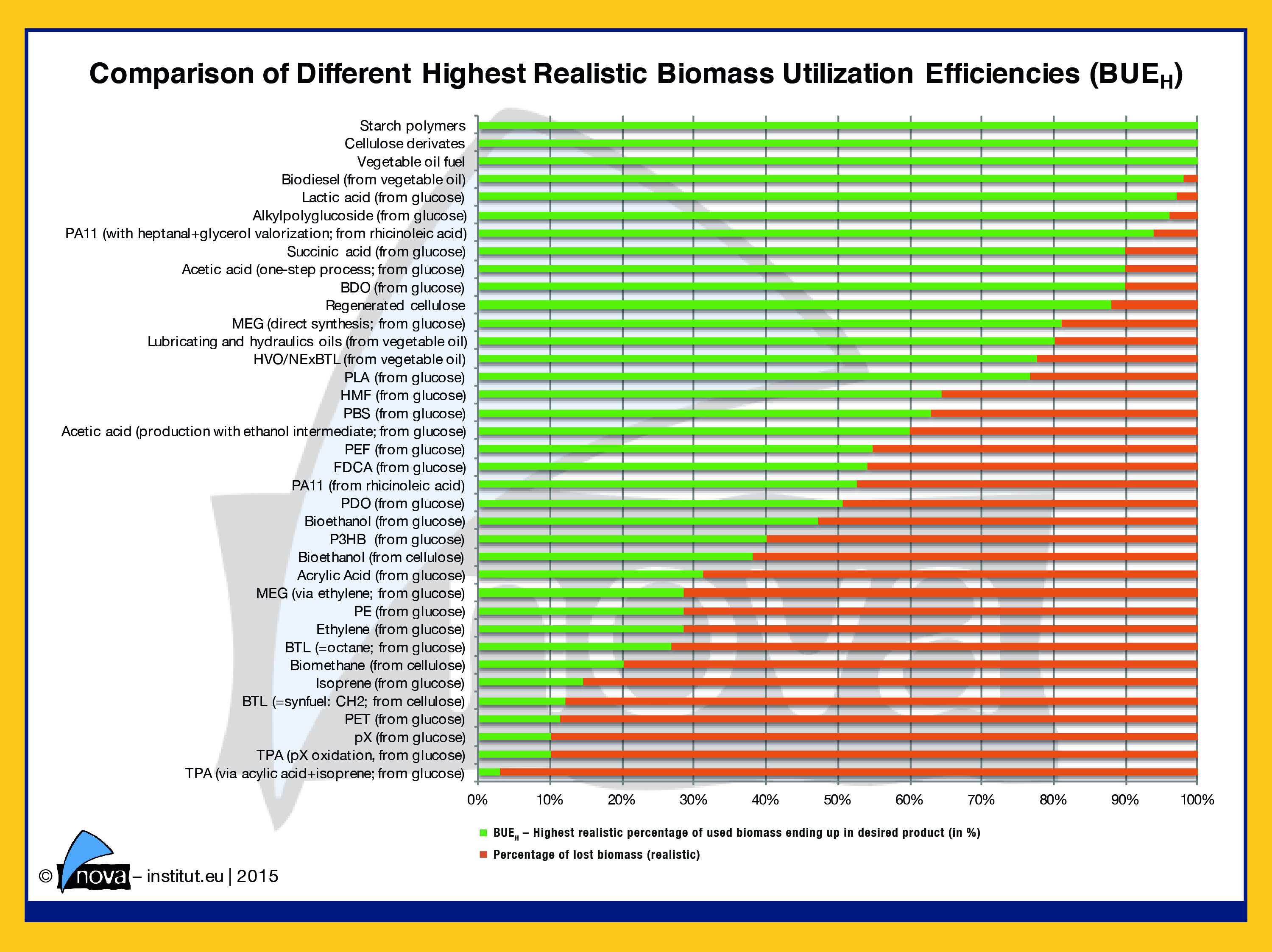

Biomass utilization efficiency (BUE) helps create awareness about alternative approaches for producing bio-based products. The difference in material efficiency between direct acetic acid production (anaerobic fermentation) and ethanol oxidation is clear (BUEH = 90% compared to 60%). The same also applies to other examples covered in the paper, the main results are shown in figure 1.

“We anticipate the relevance and importance of insightful BUE calculations will increase as the bio-based chemical industry adapts to growing economic and material competition for resources.”, says Kerstin Iffland, the main author of the nova-paper. She also points out: “This paper shows that it is important to combine the right molecule with the right process in the right application. Molecules that have low oxygen content are more suitable for energetic purposes whereas molecules with higher oxygen content (and additional functional groups) are more suitable to create material with specific chemical properties.”

Download of the full paper at www.bio-based.eu/nova-papers

Graphics included in this press release can be downloaded at the following link (free for press, please include the source): http://bio-based.eu/media/2015/11/15-11-02-Comp-diff-high-real-BUEH.jpg

Citation of the paper:

Authors: Iffland, K., Sherwood, J., Carus M., Raschka, A., Farmer, T., Clark, J. 2015: Definition, Calculation and Comparison of the “Biomass Utilization Efficiency (BUE)” of Various Bio-based Chemicals, Polymers and Fuels, Hürth 2015-11.

This press release as PDF file: 15-11-03 PR Biomass Utilization Efficiency nova

Responsible under press legislation (V.i.S.d.P.):

Dipl.-Phys. Michael Carus (Managing Director)

nova-Institut GmbH, Chemiepark Knapsack, Industriestraße 300, DE-50354 Hürth (Germany)

Internet: www.nova-institute.eu – all services and studies at www.bio-based.eu

Email: contact@nova-institut.de

Phone: +49 (0) 22 33-48 14 40

nova-Institute is a private and independent institute, founded in 1994; nova offers research and consultancy with a focus on bio-based and CO2-based economy in the fields of feedstock, techno-economic evaluation, markets, LCA, dissemination, B2B communication and policy. Today, nova-Institute has 25 employees and an annual turnover of more than 2 million €.

Source

nova-Institut GmbH, press release, 2015-11-03.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals