- DOMAMID® MBB (Mass-Balanced Biocircular) grades offer customers high quality polyamides with a reduced carbon footprint

- Mass balance enables the development of more sustainable alternatives for your final application without requiring product approval or modifications to the manufacturing process.

In line with our corporate mission to develop polyamide solutions that contribute to a more sustainable world, DOMO has adopted the mass balance approach with the aim of providing bio-based raw materials to our customers.

The entire portfolio of DOMAMID® PA6 base polymers is now available with the International Sustainability and Carbon Certification (ISCC) PLUS certification, offering increased customer choice while maintaining high quality standards.

ISCC PLUS is a globally recognized certification that focuses on sustainable production through the mass balance approach. This innovative method seamlessly integrates bio-circular and circular materials into existing production processes, ensuring meticulous tracking and verification from their entry into the production process to the final product. This Chain of Custody is supported by Circularise, a provider of mass balance software solutions.

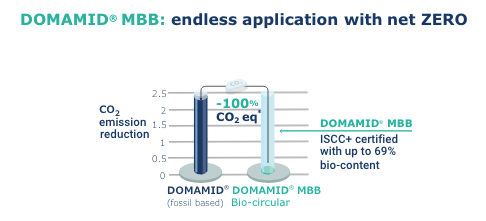

DOMO Chemicals now offers an extended range of medium, high and low viscosity DOMAMID® MBB (Mass Balanced Biocircular) solutions with up to 69% bio content without compromising performance.

Not competing with the food value chain

At DOMO, we prioritize bio-circular materials, which are derived from waste of biological origin (like used cooking oil), and circular-technical materials, which come from non-biological waste (such as textiles, plastics, and end-of-life applications). We focus on these over pure bio materials derived from agricultural sources that compete with the food value chain.

Key benefits of Mass Balance

- Enables faster transition to sustainable alternatives

- Reduces fossil-based feedstock and waste generation

- Provides the same high quality products you’re used to, now with bio-derived, renewable materials

- No need to re-homologate

- Up to 69% renewable content

- Identical prime grade properties

- Third party certified

- Traceability Chain of Custody powered by Circularise

Endless application with net ZERO

These solutions reduce CO₂ emissions by up to 100% compared to virgin-based materials produced in the same facility. These materials, which have an incredibly low CO₂ footprint, are perfect for food and pharmaceutical packaging, technical and textile yarns, and as a base for innovative engineering plastics solutions.

DOMO Chemicals invites customers and stakeholders to explore these sustainable solutions and join in advancing environmental responsibility in the industry.

To know more about the mass balance approach and how it works

© DOMO Chemicals

Source

DOMO Chemicals, press release, 2025-05-20.

Supplier

Circularise

DOMO Chemicals

International Sustainability & Carbon Certification (ISCC)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals