PLA(polylactic acid) is one of the most produced and used bioplastic. It is adapted to classical processing equipments and allows the manufacturing of food-contact packagings, bottles for cosmetics application, textile fibres etc. Despite the advantages given by its biobased origin (synthesized from renewable resources) or its compostability at its end of life (certified according to EN 13432:2000), its use remains limited since its market introduction.

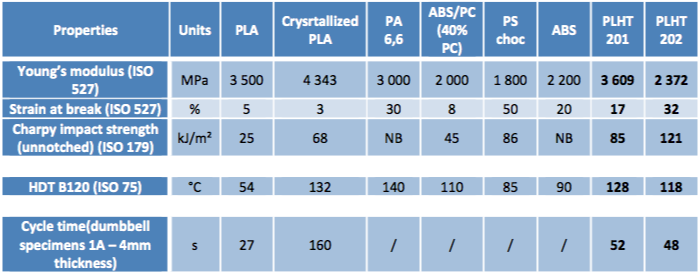

From a technical point of view, PLA drawbacks are its mechanical (low impact resistance) and thermal (heat resistant up to 55°C) properties. Since a few years, heat-resistant PLA grades (thermal stability up to 120°C) exist on the market. In injection moulding however, these improvements are obtained at the cost of productivity, the cycle time being significantly higher compared to a non- modified PLA.

Natureplast, through its subsidiary Biopolynov, now proposes new PLA grades to answer these multiple challenges: improved mechanical and thermal properties compared to standard PLA, and improved productivity compared to existing heat-resistant PLA grades, at a competitive price!

Natureplast’s new grades, PLHT 201 and PLHT 202, offer comparable if not superior thermal and mechanical properties to equivalent existing materials. Trials made also allowed gain in cycle times from 30% up to more than 200%, depending on injected parts!

These new materials are well adapted to products made by injection moulding. Natureplast’s knowledge and know-how also allow adapting these products to various books of specifications. These adaptations also concern processability, to use these grades in extrusion and thermoforming.

The properties of these compounds are equivalent to those of conventional technical materials. PL HT 202 can be compared to ABS, and is even superior when talking about thermal and impact resistances! This impact resistance is also of great interest for any application traditionally made out of high impact PS, PL HT grades being more than 40% better. Due to these properties, fields of applications, where until now bioplastics are under used, can be targeted: automotive, electronic consumer goods. With adapted properties, PL HT grades also offer a biobased solution. The blends versatility, as well as the choice of the components used, also permits applications in the food industry, for example as substitute of PP or hdPE.

About Natureplast group

Natureplast group is dedicated to supporting converters and end users into their technology transfer to bioplastics (plastics from renewable resources and/or biodegradable).

The head office of NaturePlast is the only company in Europe that supplies all bioplastics from around the world (from a hundred of producers) since 2006.

Its subsidiary Biopolynov, created in 2010, is still the only R&D European center dedicated to these new materials.

Biopolynov’s aim is to modify/improve bioplastics properties according to a functional book of specifications, while keeping actual production tools.

We support innovation projects in all fields of application: packaging (food, cosmetic etc.), agriculture/horticulture, transport, construction, toys etc.

Contact

Natureplast – Biopolynov

11 rue Francois Arago;

14 123 IFS; France

Tel:+33(0)231835087

Source

Natureplast, press release, 2015-02-10.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals