Natural fibres such as flax, hemp, jute or kenaf are used in large quantities in the automotive industry to reinforce plastics. For years, the detailed and transparent assessments of the German nova-Institute have been the reference for the European automotive industry. Now the first comprehensive update is available, which contains new findings and processes especially for hemp from Europe and kenaf from Bangladesh. The transparency with regard to all inventory data, assumptions and allocation methods guarantees the high resilience of the results and once again meets the requirement for a reference.

Deutsche Fassung: http://nova-institute.eu/press/?id=104

The 57-page study “Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material – Study providing data for the automotive and insulation industry” was conducted in 2018 and published in March 2019. The report is freely available and can be downloaded at https://renewable-carbon.eu/publications/product/carbon-footprint-and-sustainability-of-different-natural-fibres-for-biocomposites-and-insulation-material

The 57-page study “Carbon Footprint and Sustainability of Different Natural Fibres for Biocomposites and Insulation Material – Study providing data for the automotive and insulation industry” was conducted in 2018 and published in March 2019. The report is freely available and can be downloaded at https://renewable-carbon.eu/publications/product/carbon-footprint-and-sustainability-of-different-natural-fibres-for-biocomposites-and-insulation-material

The main authors of the study are Niels de Beus, life cycle assessment expert at nova-Institute, and CEO Michael Carus, who has been dealing with the subject of natural fibres for more than 20 years.

The update was based on the results of the European research project MultiHemp (FP7/2007-2013, grant agreement n° 311849) and developed in cooperation with the European Industrial Hemp Association (http://www.eiha.org) as well as the German automotive supplier Dräxlmaier, which has set up a new process chain for kenaf fibres in Bangladesh.

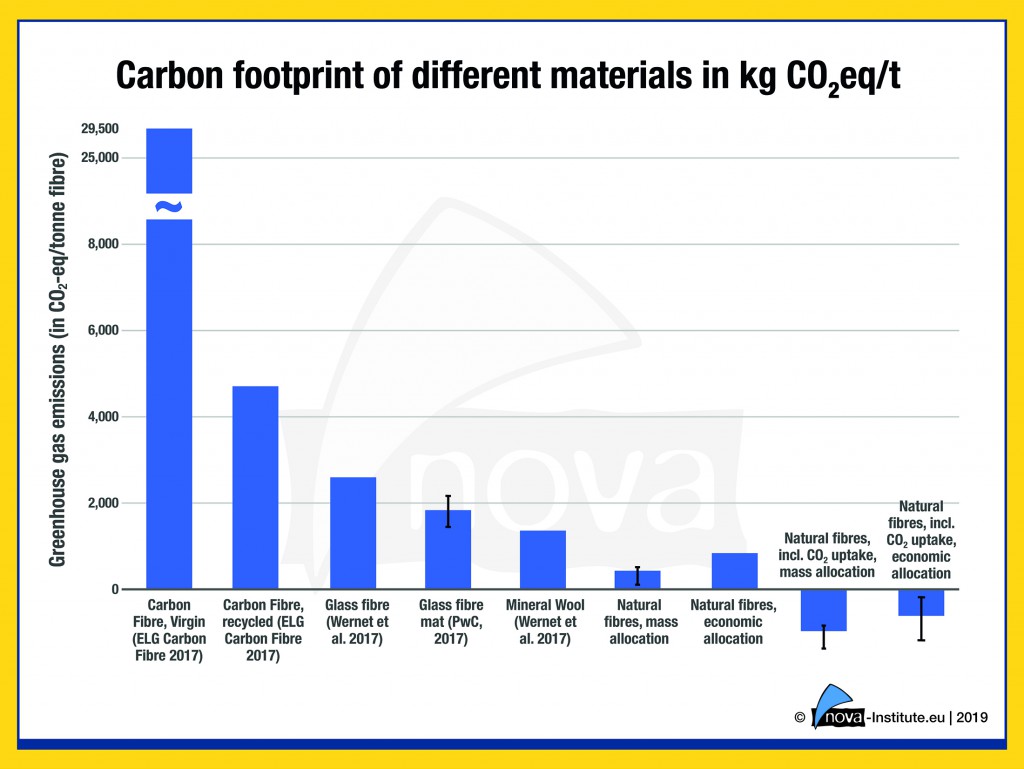

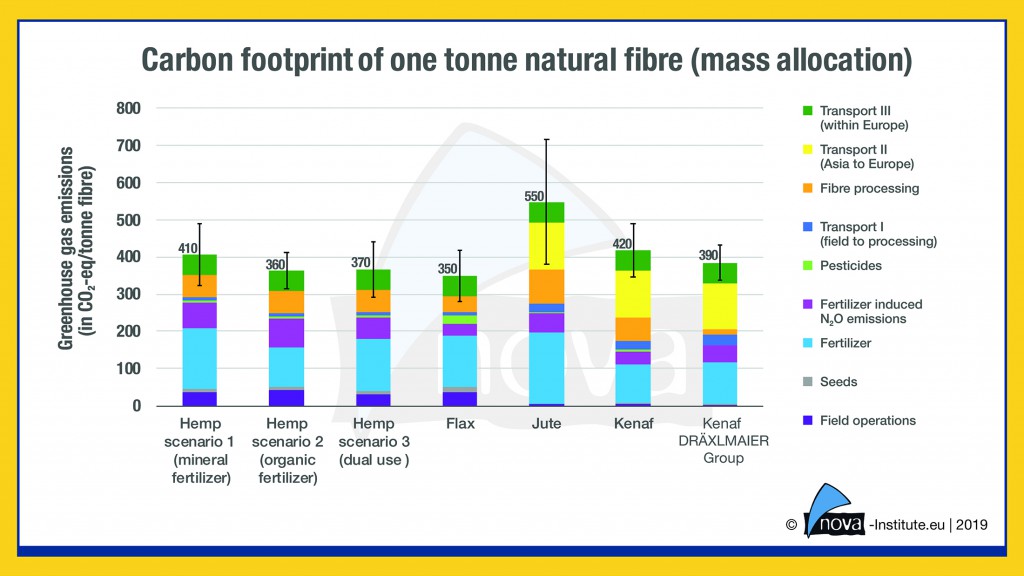

The carbon footprint of natural fibres such as flax, hemp, jute or kenaf is much lower than their counterparts glass and mineral fibres. The production of 1 tonne of glass fibres shows a carbon footprint of about 1.7–2.5 tonnes CO2-eq per tonne of fibre, whereas natural fibres only have a carbon footprint of about 0.35–0.55 tonnes CO2-eq per tonne of fibre (until the factory gate, excluding transport to the customer, using mass allocation). This is an 80% lower carbon footprint than that of glass fibres. However, the initial advantage natural fibres have over glass fibres decreases until the final product, because further processing steps partly worsen their carbon footprint. Nevertheless, natural fibre composites have an about 50% lower carbon footprint compared to glass fibre composites.

The carbon footprint of natural fibres such as flax, hemp, jute or kenaf is much lower than their counterparts glass and mineral fibres. The production of 1 tonne of glass fibres shows a carbon footprint of about 1.7–2.5 tonnes CO2-eq per tonne of fibre, whereas natural fibres only have a carbon footprint of about 0.35–0.55 tonnes CO2-eq per tonne of fibre (until the factory gate, excluding transport to the customer, using mass allocation). This is an 80% lower carbon footprint than that of glass fibres. However, the initial advantage natural fibres have over glass fibres decreases until the final product, because further processing steps partly worsen their carbon footprint. Nevertheless, natural fibre composites have an about 50% lower carbon footprint compared to glass fibre composites.

The carbon footprints of the different natural fibres (flax, hemp, jute and kenaf) are not significantly different. In the range of uncertainty, the carbon footprint to the factory gate of the European nonwoven producer in the automotive or insulation sector is about 400 kg of CO2-eq per tonne of natural fibre for all four natural fibres, when applying mass allocation. Jute and kenaf show less emissions during cultivation, harvesting and decortication because of manual processing, but long transport to Europe levels this advantage.

When economic allocation is used, more of the greenhouse gas emissions stemming from plant cultivation and processing are placed on the fibres, as their value is higher than the by-products’ value. The carbon footprint of natural fibres using economic allocation is around 900 kg of CO2-eq per tonne of natural fibre.

Because fertilizers have a high share in the total calculation of emissions, substituting mineral fertilizers by organic fertilizers leads to a lower carbon footprint of 360 kg of CO2-eq per tonne of hemp fibre instead of 400 kg of CO2-eq/t (mass allocation). Using organic fertilizer is only possible if the crop and the region are suitable. Currently pig slurry and fermentation residues are only used for hemp grown in the north of the Netherlands and Germany. Furthermore, it is shown that cultivating hemp for both seeds and straw reduces the carbon footprint of the hemp fibre. This effect is significant when using economic allocation due to the high value of the seeds.

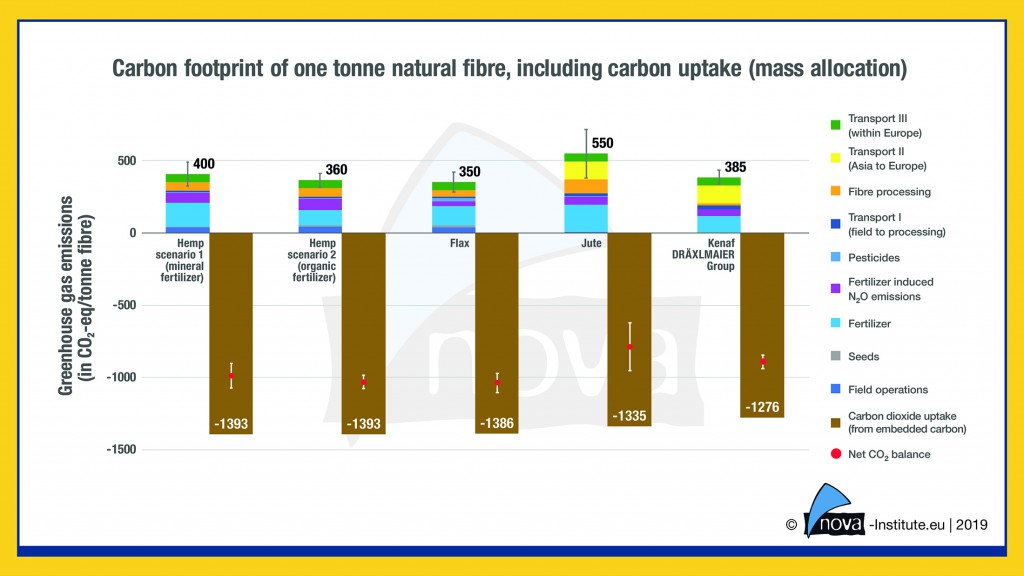

When CO2 uptake is considered, which is responsible for the carbon in the fibre, the GHG emissions for the natural fibres is greatly reduced. At the entry gate of the non-woven producer the numbers are even negative, indicating that the CO2 removed from the air is larger than the GHG emissions up to that point.

European hemp fibres that have an ISCC PLUS sustainability certificate, which demands much more than a carbon footprint, have become available on the world market. Hopefully other fibres will follow.

The results of the study will be presented to the public for the first time and discussed at the 16th EIHA Hemp Conference, June 5-6 in Cologne, the world’s largest conference on industrial hemp with 400 expected participants from 50 countries. http://www.eiha-conference.org

Download this press release as PDF file and visuals free for press purposes at http://nova-institute.eu/press/?id=104

Author

Niels de Beus, Michael Carus, Martha Barth

Source

nova-Institut GmbH, press release, 2019-04-02.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals