- On-site use of captured CO2 at power plant will turn entire Seifu Shinto suburb carbon negative

- Through proprietary CO2 capture technologies, MHIENG provides diverse solutions for small-scale facilities

Mitsubishi Heavy Industries Engineering, Ltd. (MHIENG), a part of Mitsubishi Heavy Industries (MHI) Group, has launched full-scale operation, on schedule, of a compact CO2 capture system ordered in November 2021 by Taihei Dengyo Kaisha, Ltd. It is the first system of its kind to go into commercial operation.

The compact CO2 capture system was installed at a 7-megawatt (MW) class biomass power plant operated by Taihei Dengyo in Seifu Shinto, a suburb of Hiroshima City. The system has the capacity to capture 0.3 metric tons per day (tpd) and is based on a highly versatile standardized design requiring an installation space of just five meters in length and two meters wide. Its modular configuration enabled rapid transportation to the site and easy installation.

The CO2 captured from the plant’s flue gas will be used for growing vegetables in on-site greenhouses – an example of the circular economy. By fully consuming all captured CO2 at its carbon-negative power plant, Taihei Dengyo looks to help prevent global warming and promote a decarbonized society. The biomass power plant where the system was installed was delivered by Mitsubishi Heavy Industries Power IDS, Ltd. in October 2019.

As the next step, MHIENG will perform demonstration test of operational support services for the plant using a proprietary remote monitoring system with the customer. MHIENG ultimately aims to put in place a fully integrated customer support package, encompassing everything from system design and delivery to after-sale servicing, operation and maintenance. MHIENG also has plans to expand its lineup of compact CO2 capture systems as well as to pursue reduced installation, operation and maintenance costs and faster deliveries. This will allow it to offer diverse solutions to the customer’s needs especially of relatively small-scale industrial and other facilities.

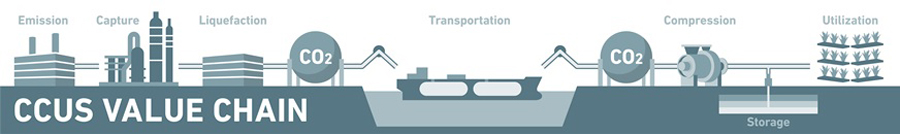

MHI Group is currently strengthening its position in the Energy Transition, and the development of a CO2 solutions ecosystem is a core component of that initiative. Carbon dioxide capture, utilization and storage (CCUS) is garnering attention as an effective means for realizing a carbon neutral society.

MHIENG, as a leading company in decarbonization and key to the group’s strategy regarding Energy Transition, will continue to help achieve wide-scale greenhouse gas emission reduction by introducing its high-performance CO2capture technology globally. It will also press ahead in developing new solutions to contribute to global environment protection.

About MHIENG’s CO2 capture technologies

Since 1990, MHIENG (originally MHI) has undertaken the development of the KM CDR Process™ (Kansai Mitsubishi Carbon Dioxide Recovery Process) and Advanced KM CDR Process™ together with The Kansai Electric Power Co., Inc. (KEPCO). As of June 2022, MHIENG has delivered 14 commercial plants adopting the KM CDR Process™, and two more plants are currently under construction. This robust track record makes MHIENG a global leader in CO2capture technologies.

For further information on MHIENG’s CO2 capture plants: https://www.mhi.com/products/engineering/co2plants.html

Source

Misubishi Heavy Industries, press release, 2022-06-30.

Supplier

Mitsubishi Heavy Industries

Taihei Dengyo Kaisha

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals