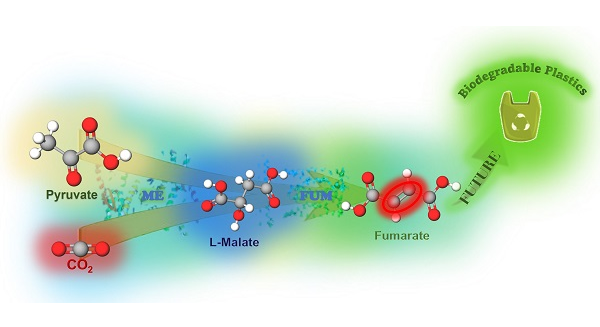

Researchers from Osaka Metropolitan University have managed to create fumarate using artificial photosynthesis on pyruvate and CO2. This fumarate can be used to make biodegradable plastic like polybutylene succinate, storing the carbon in a compact, durable, solid form. Currently, most fumarate used to make this plastic is produced from petroleum, so creating fumarate from CO2 and biomass-derived pyruvate is highly desirable.

Technology sequesters CO2 emissions

In plants, natural photosynthesis binds carbon dioxide (CO2) to organic compounds, which can then be converted into glucose or starch. These useful molecules can be sequestered, storing the carbon in a solid form. Artificial photosynthesis mimics this process by reducing the greenhouse gas CO2—the main cause of climate change—which is converted into other useful substances.

Malate dehydrogenase (ME) combines pyruvate and carbon dioxide (CO2) into L-malate, which can be converted into fumarate by fumarase (FUM). The fumarate can be used as a feedstock for biodegradable plastic, like polybutylene succinate, which are typically produced from petroleum, while sequestering CO2.

Professor Yutaka Amao from the Research Center for Artificial Photosynthesis and Mika Takeuchi, a graduate student at the Osaka Metropolitan University Graduate School of Science, used the biocatalyst malate dehydrogenase (oxaloacetate-decarboxylating) to combine CO2 with pyruvate, derived from biomass, to produce L-malic acid. Subsequently, the biocatalyst fumarase was used to dehydrate the L-malic acid to synthesize fumarate.

“The biocatalysts were used to convert CO2 into a raw material for plastic. Based on our results, we will continue to construct better CO2 conversion systems with an even lower environmental impact; we are aiming for more efficient conversion of CO2 into useful substances, using light energy,” said Prof Amao.

With this success, the team has already begun researching new methods of artificial photosynthesis with the goal of producing fumarate using light as energy. If this technology can be realized, it will create a new artificial photosynthetic system to synthesize useful macromolecules from CO2.

Funding

This work was partially supported by the Grant-in-Aid for Scientific Research Fund for the Promotion of Joint International Research (Fostering Joint International Research (B)) (19KK0144).

Publication

Title: Biocatalytic fumarate synthesis from pyruvate and CO2 as a feedstock

Journal: Reaction Chemistry & Engineering

DOI: 10.1039/D2RE00039C

Author: Mika Takeuchi and Yutaka Amao

URL: https://doi.org/10.1039/D2RE00039C

Contribution to SDGs

7: Affordable and clean energy

12: Responsible consumption and production

Contact

Research Center for Artificial Photosynthesis

Prof. Yutaka AMAO

E-mail: amao@omu.ac.jp

Source

Osaka Metropolitan University, press release, 2022-08-22.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals