Located in Châteauneuf-les-Martigues, near Marseille, France, the La Mède complex includes a biorefinery with a production capacity of 500,000 metric tons of renewable diesel per year, an AdBlue production plant, a logistics and storage hub, an industrial-scale training center, a solar farm, a production unit for recycled fuels and a test platform for the production of microalgae.

Location: Châteauneuf-les-Martigues, France

Operations: HVO biodiesel, biojet, Avgas and AdBlue production, logistics and storage hub, training center offering real facilities, solar farm

Capacity: 500,000 metric tons per year of HVO biodiesel

Start of production: July 2019

“Biofuels are fully renewable and an immediately available solution to cut carbon emissions from ground and air transportation. When produced from sustainable raw materials, as at La Mède, they emit at least 50% less carbon than fossil fuels.”

Bernard Pinatel President, Refining & Chemicals, TotalEnergies

France’s first world-class biorefinery

Biofuels are a source of renewable energy that contribute directly to combating climate change, guaranteeing at least a 50% reduction in CO2 emissions compared with fossil-based equivalents.

The commitment

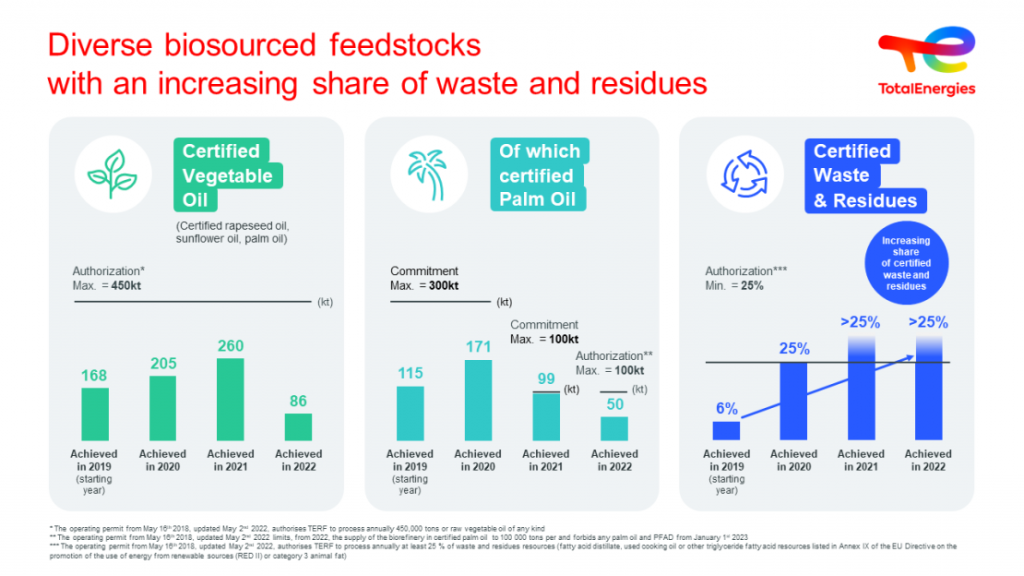

Since it started operations in July 2019, the La Mède biorefinery has demonstrated that it can process a wide variety of certified raw materials, from rapeseed and other vegetable oils, to waste sourced from the circular economy, such as used cooking oils and animal fats.

TotalEnergies has committed to cease sourcing certified palm oil and PFAD from 1 January 2023 and to limit the amount to 100.000 t/year in 2021 and 2022.

TotalEnergies also reserves an increasing share for resources from waste and residues in its supply plan.

As part of the update of the supply plan, the La Mède biorefinery will receive, within the limit of 650,000 tonnes/year :

- a maximum of 450,000 tons/year of vegetable oils of all kinds, excluding palm oil, from 1 January 2023;

- a minimum of 25% of resources from waste and residues, excluding PFAD from 1 January 2023.

Supplying sustainable raw materials

All oils purchased by TotalEnergies for La Mède meet the sustainability criteria set by the European Union.

An International Sustainability & Carbon Certification (ISCC) sustainability certificate or similar, based on the mass balance system required by the European Union,* attests that the oils purchased for the La Mède biorefinery are compliant with sustainability criteria. This certificate confirms that every metric ton of oil processed by TotalEnergies at La Mède corresponds to one metric ton of oil produced in compliance with the European Union’s sustainability criteria.

The certificate is awarded if the oils meet the following sustainability and traceability criteria across the entire chain, from their origin to the refinery:

- At least a 50% reduction in CO2 emissions compared with fossil fuels.

- No plantations on land deforested after 2008.

- Farming practices that protect biodiversity.

- Respect for human rights.

Spotlight on ISCC mass balance certification

Compliance of purchased oils with sustainability criteria is attested by an International Sustainability & Carbon Certification (ISCC) sustainability certificate or similar, based on the mass balance system required by the European Union.* This certificate confirms that every metric ton of oil purchased and processed by TotalEnergies corresponds to the production of one metric ton of oil in compliance with the European Union’s sustainability criteria.

The mass balance system requires information about the plantation and mills associated with sustainability certificates to be traceable. It makes it possible to accurately track the amount of oil certified as sustainable without requiring a specific supply chain to be set up.

* See Article 18, paragraph 1 of E.U. Directive 2009/28/EC of April 23, 2009 on the promotion of the use of energy from renewable sources

Until the end of use of palm oil, TotalEnergies continues to round out its palm oil certification with strengthened control measures regarding sustainability and respect for human rights.

- TotalEnergies works with a limited number of responsible suppliers to ensure it can draw up improvement plans with them and oversee their implementation.

- Suppliers are required to join the Roundtable on Sustainable Palm Oil (RSPO)#, committing to contribute to the industry’s efforts to achieve sustainable palm oil.

- Suppliers are also required to sign the Company’s Fundamental Principles of Purchasing and comply with its Code of Conduct.

- A team is formed to oversee supplier sustainability checks, and a third-party expert commissioned to assess each shortlisted supplier’s respect for human rights.

TotalEnergies fosters constructive dialogue with its suppliers, certifying bodies, other energy industry companies, NGOs and technical experts to continuously improve the sustainability of its raw material purchases for the La Mède biorefinery.

# The Roundtable on Sustainable Palm Oil (RSPO) is an organization that was created in 2004 by producers, manufacturers and NGOs who wanted to join forces in a responsible and sustainable approach to palm oil production.

A flexible, multimodal storage logistics hub

A new logistics and storage hub for diesel, gasoline, jet fuel and heating oil started operations in April 2017. With a capacity of 1.3 million cubic meters, it contributes to the activity of the Marseille Fos Port.

An AdBlue production plant

An AdBlue production plant with a capacity of 50,000 cubic meters per year has been set up on site. AdBlue is an additive that reduces nitrogen oxide emissions from diesel engines in trucks and passenger vehicles.

Development of Avgas production

The La Mède site transformation project includes plans to develop the production of Avgas (a fuel used in civil aviation). TotalEnergies is France’s sole producer of Avgas.

The reforming unit also enables us to supply the local petrochemical industry and provide the necessary hydrogen to the biorefinery.

An OLEUM training center

The facility hosts TotalEnergies’s second OLEUM training center. Modeled after the center of the same name at our Flanders facility near Dunkirk in northern France, this training center for oil and petrochemicals industries is one of the world’s few such facilities based in a real industrial complex. The center is able to train more than 2,000 people a year.

The La Mède OLEUM center also provides a digital demonstration platform to trial Company digital projects under real operating conditions in TotalEnergies’s industrial environment.

A high-efficiency solar farm

In late 2017, a solar farm equipped with high-efficiency cells produced by the Company’s affiliate SunPower came on stream at the La Mède facility. It has a production capacity of 8 megawatts, enough to meet the energy needs of a city of 13,000 people.

Ecoslops, a recycled fuel production unit

The Ecoslops P2R1unit started up in July 2021 at the La Mède site. The production of the first litres of recycled fuel is the result of a partnership signed in 2019 between TotalEnergies and Ecoslops SA2, an innovative company that produces fuel and light bitumen from “slops” (hydrocarbon residues such as bilges) from maritime transport.

The Ecoslops unit will produce up to 30,000 tons per year of recycled fuels (Naphtha, Gasoil and Fuel Oil) and light bitumen from these residues. This circular economy model applied to petroleum waste allows the revalorisation of these residues from maritime transport and the creation of value locally.

A test platform for the production of microalgae

TotalEnergies and Veolia have joined forces to accelerate the development of microalgae cultivation using CO2. The two partners will pool their know-how to develop a four-year research project at the La Mède site, with the long-term goal of producing biofuel.

Through photosynthesis, microalgae use sunlight and CO2 from the atmosphere or from industrial processes to grow. When mature, they can be transformed into next-generation biofuels with low carbon intensity.

As part of the project, a test platform will be set up to compare different innovative systems for growing microalgae and identify the most efficient ones.

Veolia will therefore bring its expertise in:

- the water sector to optimize management of the microalgae’s aquatic environment,

- the development of algal biomass as an effective solution for CO2 capture.

TotalEnergies, in synergy with the business lines at the La Mède site, will bring its expertise in:

- the cultivation and refining of biomass to produce advanced biofuels,

- CO2 capture and utilization technologies.

1Petroleum Residues Recycling

2TotalEnergies holds a 25% stake in the subsidiary Ecoslops Provence

Source

TotalEnergies, press release, 2023-06-26.

Supplier

International Sustainability & Carbon Certification (ISCC)

TotalEnergies

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals