Forward-thinking companies around the world that are focused on creating more products with sustainability in mind, are looking to their suppliers to partner with them to make this a reality. One of Trinseo’s key customers, Arçelik, a leading global manufacturer of home appliances, part of Koç Group, is one of those companies.

In fact, increasing plastic recycled content in their products to 40% and increasing bio-attributed material content to 5% are part of Arçelik’s 2030 sustainability goals. To realize this target, the company started a Recycled Content Project in their production facilities around the world. One result is the development of Arçelik’s Bio-fridge, which uses Trinseo’s bio-Polystyrene (PS) in its liner and drawer parts. This new product line was introduced by Arçelik at IFA Berlin 2023, the largest home appliance and consumer electronics trade show in the world, which opened on September 1, 2023.

Procuring all bio-PS from Trinseo, Arçelik is one of the first manufacturers to use bio-attributed PS in making premium fridges. The materials for the fridge liner and fridge drawers are Trinseo’s BIO PS grades. Trinseo’s bio-attributed PS helps support Arçelik’s research and development focus on developing high-performance and eco-friendly recycled plastic formulations to replace their virgin counterparts without sacrificing the durability of their products. Trinseo’s BIO PS is produced using ISCC PLUS Mass Balance principles to certify bio-attributed content, which in turn works to help maximize carbon footprint reduction. Trinseo’s BIO PS also works as a drop-in replacement for fossil-based equivalents, with the same performance as virgin materials.

“The challenge with all sustainable materials is securing feedstock. Trinseo is advantaged in this regard, since not only do we own a recycling operation enabling us to have access to the expertise and know-how of a network of plastics waste streams, but we’ve been a pioneer in different recycling technologies, having developed the broadest sustainably advantaged PS portfolio using dissolution, bio, chemical and mechanical recycling methods. Trinseo is proud to collaborate with Arçelik, in helping make the unique Bio-fridge using bioplastics,” said Alain Minelli, Product Director Polystyrene EMEA.

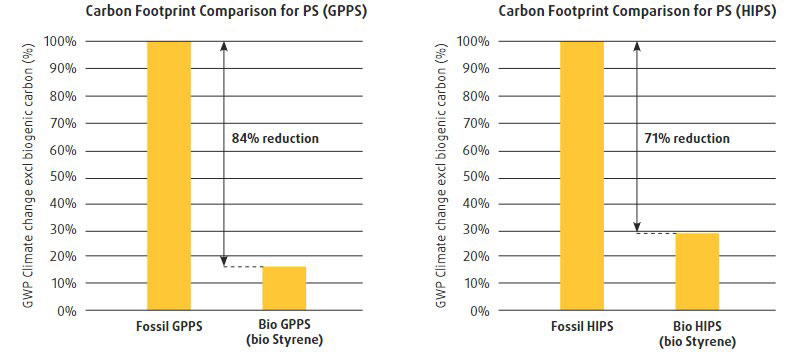

Trinseo has been offering STYRON™ BIO85 HIPS and STYRON™ BIO95 GPPS with styrene monomer replacement since 2021. Both result in a Product Carbon Footprint (PCF) reduction, with the decrease being 71% and 84% respectively compared to benchmarking fossil-based materials.

Both GPPS and HIPS in their fossil-based and bio-attributed formulations are versatile materials that can be used in a variety of applications ranging from home appliances to medical applications to food packaging and building insulation.

Source

Trinseo, press release, 2023-09-12.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals