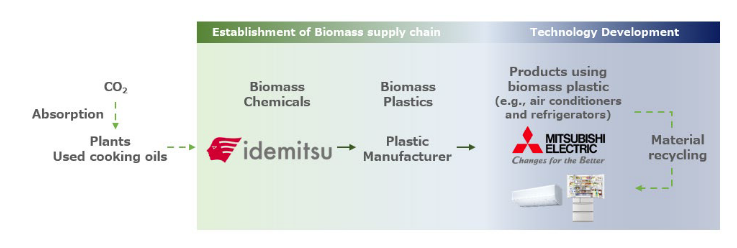

Idemitsu Kosan Co., Ltd. (hereinafter, “Idemitsu Kosan”) and Mitsubishi Electric Corporation (hereinafter, “Mitsubishi Electric”) are pleased to announce that they have agreed to start collaboration for use of biomass plastics in home appliances, with the aim of promoting biomass plastics in the home appliance market. Idemitsu Kosan will produce biomass chemicals using the mass balance method. Mitsubishi Electric aims to use biomass plastics made from the chemicals for Mitsubishi Electric’s home appliances (e.g., air conditioners and refrigerators).

Biomass plastics made from biomass chemicals are considered to have the following characteristics compared to petroleum-derived plastics.

- CO2 emissions could be reduced throughout their life cycle because they are manufactured from raw materials derived from renewable materials such as plants, used cooking oils, etc.

- They can be used in home appliances without inhibiting material recycling because they are the same quality as petroleum-derived plastics.

Idemitsu Kosan has been working on the production and sales of biomass chemicals as one of its measures to realize carbon neutrality since 2022. Mitsubishi Electric is also working to expand the use of recycled plastics to realize a circular economy. In addition to current activity, it is essential to develop alternative materials to petroleum-derived plastics and technologies and products which leads to reduction of CO2 emissions. To solve this issue, the two companies will work together to use biomass plastics made from biomass chemicals in home appliances, and contribute to carbon neutrality regarding plastics and the realization of a circular economy.

*1: Mass balance method

A method in which raw materials with certain characteristics (e.g., biomass-derived raw materials) are mixed with other raw materials (e.g., petroleum-derived raw materials) in the processing and distribution process from raw materials to finished products. These characteristics are assigned to a portion of the product in accordance with the amount of input of raw materials with the same characteristics. In the chemicals industry, where products are typically manufactured through multiple production processes, the mass balance method is considered an effective approach to accelerate the spread of biomass products in the supply chain.

*2: Material recycling

A method of sorting and processing raw materials recovered from used products and waste for reuse. Mitsubishi Electric has technology for sorting and recovering plastics recovered from used home appliances by utilizing differences in their physical properties, such as specific gravity and friction-charging characteristics.

Reference

Building a supply chain for biomass plastics (Idemitsu Kosan Website) https://www.idemitsu.com/en/business/basic_chemicals/bioplastic/index.html

Defining a Recycling-Based Society (Mitsubishi Electric Website)

https://www.mitsubishielectric.com/en/sustainability/environment/ecotopics/plastic_sp/d

efining/index.html

Source

Mitsubishi Electric and Idemitsu Kosan, joint press release, 2025-02-21.

Supplier

Idemitsu Kosan Co. Ltd.

Mitsubishi Electric Corporation

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals