With a groundbreaking innovation, the start-up ICODOS, in collaboration with the Karlsruhe Institute of Technology (KIT) and the Mannheim municipal sewage treatment plant (EBS), is setting new standards in sustainable fuel production. In a plant that is the first of its kind in the world, renewable electricity and wastewater are being used to produce sustainable ship fuel for the first time. This pioneering project demonstrates the enormous potential of sewage treatment plants as an energy source – there are around 9,000 in Germany alone, and up to 75,000 across Europe.

A flagship project for the maritime energy transition

ICODOS GmbH is a climate tech start-up based in Mannheim. Originating from a research project at the Karlsruhe Institute of Technology (KIT), the company specialises in producing sustainable fuels and chemicals from renewable sources such as biogas and CO₂ in combination with renewable electricity.

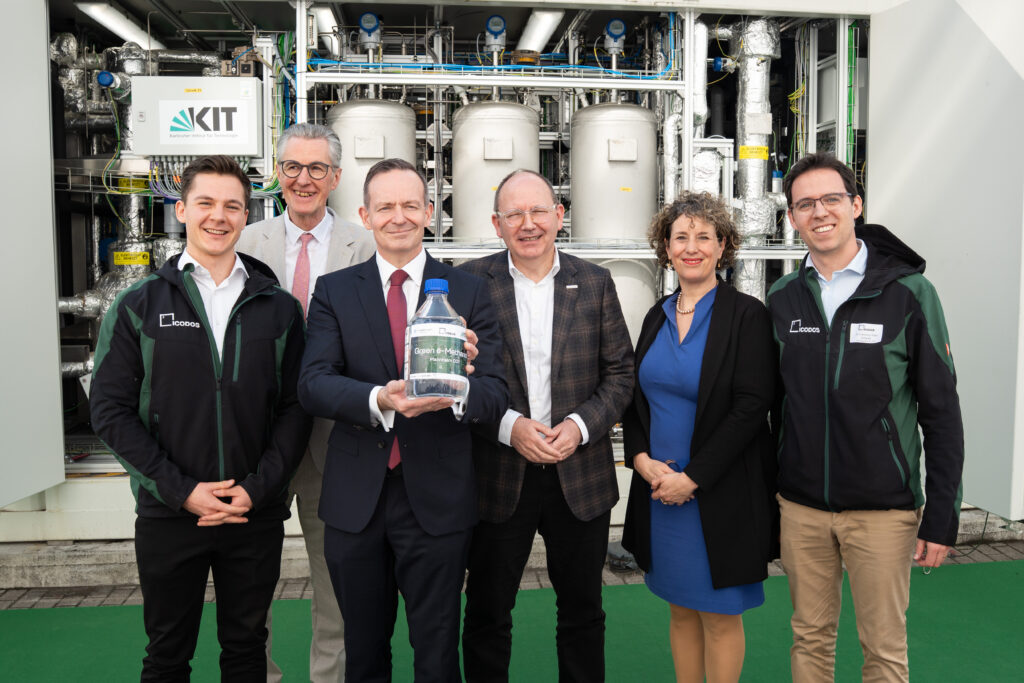

The Mannheim plant represents a major step forward for the shipping industry. The importance of the project is also emphasised by Federal Transport Minister Dr. Volker Wissing: “In order to achieve our climate protection goals, we must keep all technological options open. In addition to electrification and hydrogen-based propulsion, we need climate-friendly fuels, especially in maritime shipping. Germany should play a pioneering role in research and development. This is a growth market of the future. It is also about making our country independent of energy imports. ‘Mannheim 001’ shows how economic efficiency and climate protection can go hand in hand. This project can serve as a model for many other locations in Germany and Europe.” (translated)

From sewage treatment plant to fuel supplier

The production process is based on the use of biogas from the Mannheim sewage treatment plant, which is further processed in a demonstration plant operated by KIT and ICODOS. Using a patented process, the biogas is purified and converted into methanol using renewable electricity and hydrogen. The electricity drives the electrolysis that produces hydrogen, which then reacts with the CO₂ extracted from the biogas. The aim of the process is to reduce unavoidable CO₂ emissions in a targeted way and thus actively contribute to the reduction of greenhouse gases. The resulting product offers a sustainable alternative for the shipping industry.

“The new plant impressively demonstrates how research and entrepreneurial spirit can produce practical solutions for the sustainable transformation of our economy,” says Prof. Thomas Hirth, Vice President Transfer and International Affairs at KIT. “Here, a recyclable material is obtained from biogas produced during wastewater treatment – an innovative approach that shows how existing resources can be used in an intelligent and climate-friendly way.” (translated)

Sustainable fuels as a future technology

Shipping is one of the world’s biggest producers of greenhouse gas emissions. While alternative drives such as hydrogen and battery technologies are on the increase in air and road transport, the maritime industry remains dependent on liquid fuels. This is where ICODOS’s technology comes in: the production of sustainable e-methanol offers an alternative for shipping.

One key advantage of the process is its scalability. While many existing e-fuel technologies rely on large-scale industrial production plants, the ICODOS approach enables cost-efficient production in smaller, decentralised units. This means that the production of sustainable fuels can be flexibly expanded and established throughout Europe.

With the plant in Mannheim, ICODOS is providing an important impetus for the sustainable transformation of the shipping and energy industries – an advance that opens up new prospects far beyond the region.

Author

Emma Schmitt

Source

KIT Gründerschmiede, press release, 2025-03-26.

Supplier

Eigenbetrieb Stadtentwässerung Mannheim (EBS)

ICODOS GmbH

Karlsruher Institut für Technologie (KIT)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals