NatureWorks LLC introduced today its second generation Ingeo™ bioresin solution targeted primarily at injection molding of semi-durable consumer products. This new patent-pending solution is the latest in a series of breakthroughs for Ingeo applications, which already include high heat thermoforms, films, and gift and transactional cards.

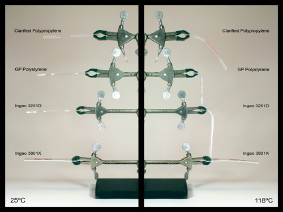

NatureWorks’ new compounded resin technology enables the production of injection molded parts with thermal dimensional stability up to 120º Celsius (248º F), notched Izod impact strength greater than two foot-pounds per inch, and modulus of ~ 450,000 psi. Injection molding cycle time compares to styrenic resins, for which the new Ingeo technology now offers a low-carbon, cost-competitive, performance replacement.

|

| © NatureWorks |

Designated Ingeo 3801X, the new formulation combines a high percentage polylactide base resin with a tailored additive package designed to achieve the high heat, impact, and cycle time performance requirements of semi-durable products such as cosmetics, consumer electronics, toys, office accessories, and promotional products. Brand owners that replace traditional plastic components with the new Ingeo formulation can reduce their dependence on non-renewable petroleum inputs and lower overall greenhouse gas emissions and energy consumption. Furthermore, brand owners are now able to source a renewable plastic resin that offers a more stable pricing structure relative to the price volatility expected of most petroleum-derived products.

“The introduction of this high heat technology demonstrates that the Ingeo family is maturing significantly, steadily broadening into a host of applications where these materials are a performance substitute for non-renewably sourced plastics,” said Marc Verbruggen, president and CEO of NatureWorks. “In the six years since we entered the market with our world-scale facility, the injection molding community has shown significant interest in our first generation product. The industry has already developed a compelling array of injection molded consumer products, with items that include lipsticks and compacts, mobile phones, and auto interior parts. Today, we’re pleased to announce support for ongoing development efforts with a product that has been custom designed to address enhanced property and performance requests.”

NatureWorks is selectively opening this proprietary technology to Ingeo compounding partners, as Verbruggen explains. “NatureWorks firmly believes that the continuing development of Ingeo solutions for durable applications is best complemented by the innovations, expertise, and capabilities that our compounding partners offer.”

Further Information

NatureWorks

Tel.: +1-800-664 64 36

Ashland, Inc.

Tel.: +1-614-790 41 88

Jamplast

Tel.: +1-636-238-21 00

Samples of the new high heat compounding solution will also be made available to Asian compounders, converters, and brand owners via regional NatureWorks sales offices:

NatureWorks Asia

+86-21-52 72 89 96

NatureWorks Japan

+81-3-52 24 57 33

While an assessment of the European Union chemical regulation REACH status is underway, research and development samples are available in Europe

NatureWorks Europe

Tel.: +31-35-694 50 56

Source

NatureWorks LLC, press release, 2010-10-14.

Supplier

Ashland Inc.

Jamplast Inc.

NatureWorks LLC

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals