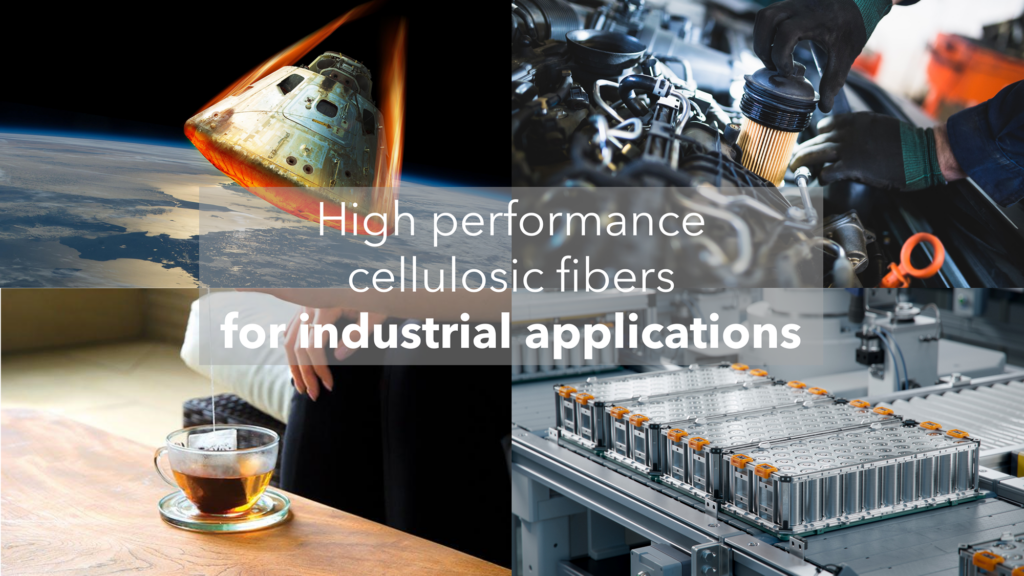

LENZING™ Industrial, the industrial application arm of Lenzing produces fibers that combine high performance with low environmental impact. The application of these LENZING™ Lyocell fibers can be found in specialized and unlikely places – even in space.

Lenzing is working to reduce the environmental footprint of industrial products, processes and machinery through working with value chain partners to implement Lyocell fibers as a cellulosic alternative to synthetic fibers. Lenzing has refined the production process over the years, steadily reducing energy consumption through continuous optimization without compromising on performance.

Lenzing fibers have a lower impact on the environment through the award-winning fiber production process, the natural biodegradability of the fiber structure (as certified by TÜV AUSTRIA), and the sustainable origin of the wood used to make the fibers. Lenzing’s wood is sustainably grown and harvested from certified and controlled sources following the guidelines of the Lenzing Wood and Pulp Policy[1]. Throughout the production process of LENZING™ fibers, solvent recovery and reuse is maximized, process water is recycled, unused components are recovered as co-products, and the use of renewable energy is optimized. The fibers are also available with FSC certification upon request.

In terms of properties, LENZING™ Industrial’s Lyocell fibers have a microfibrillar structure, good thermal stability[2]and chemical resistance[3] that enables a wide range of technical applications and products, including filter media, electrical separators, and aerospace applications.

LENZING™ Lyocell Shortcut fibers are well suited for a variety of filtration applications including industrial and automotive air and liquid filters. As these fibers are certified safe for food contact, they are also suitable for food and beverage filtration such as lightweight tea bags and coffee filter papers, and high-capacity depth filters.

The microfibrillar structure and thermal stability of LENZING™ Lyocell Shortcut fibers make them a suitable ingredient in electrical separators for applications such as lithium-ion batteries, supercapacitors and electrolytic condensers, particularly in the automotive sector and the new generation of electric vehicles. Separators made of LENZING™ Lyocell fibers perform well, have good dimensional stability over a wider temperature range compared to polyolefin-based separators and show low internal resistance for high current flows. Furthermore, they offer excellent cycling stability, which is reflected in prolonged battery life.

A component of aeroshells known as Domestic Phenolic Impregnated Carbon Ablators (PICA-D) and part of the rigid casings that help protect spacecraft from extreme heat (above 3,800°C[4]) uses LENZING™ Lyocell fibers because their low alkaline metal content makes them suitable as the precursor for carbon fibers used in these heat shields. These carbon fibers based on LENZING™ Lyocell fibers have low thermal conductivity, low density, high purity, and excellent ablation resistance – all important components for aerospace and high-temperature industrial applications such as ablative and heat shield applications.

The above examples showcase only a fraction of the wide variety of applications where LENZING™ Industrial fibers are used for their high-performing characteristics. There are more applications on the horizon as Lenzing and its value chain partners continue to innovate, break boundaries and exceed expectations.

With decades of experience, Lenzing will continue to reshape the industry to offer the best premium, high performing lyocell fibers with low-environmental impact for a wide range of industrial applications.

Additional applications can be explored on our website.

[1] Please refer to Lenzing Wood & Pulp Policy (lenzing.com).

[2] The low alkali metal content of LENZING™ Lyocell fibers makes them suitable to produce carbon fibers with good thermal stability, suitable for heat shield applications.

[3] LENZING™ Lyocell fibers are resistant to chemical degradation by fuels and oils, commonly used and found in the automotive industry

[4] https://www.nasa.gov/ames/core-area-of-expertise-entry-systems/

Source

Lenzing, press release, 2025-08-09.

Supplier

Lenzing Gruppe

TÜV AUSTRIA Group

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals