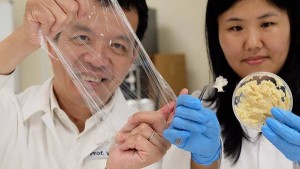

A professor of food science and technology at Singapore’s Nanyang Technological University, William Chen has invented a biodegradable food wrap made of cellulose and extracted from the waste generated by soybean product manufacturers.

A professor of food science and technology at Singapore’s Nanyang Technological University, William Chen has invented a biodegradable food wrap made of cellulose and extracted from the waste generated by soybean product manufacturers.

The soybeans are first crushed to squeeze out juice that’s used to make bean curd and soy milk. The residue is then fermented by microbes that consume the nutrients, leaving behind cellulose, a form of fiber.

Cellulose-based plastic wraps have been on the market for a few years but Chen says that most are made from wood or corn, cultivated for that purpose. By contrast, his wrap is made from a waste product — so it doesn’t compete with edible crops for land and is more sustainable.

Chen’s technology could help to solve two problems at once: cutting plastic production and reducing the amount of food waste deposited in landfill. “In Singapore, the amount of food waste we generate every year can fill up 15,000 Olympic-sized swimming pools,” he says, adding that because soy products are so popular in Singapore, 30 tons of soybean residue is produced there every day.

F&N, a soy-based drinks producer, has partnered with Chen’s lab and provides the residue, straight from the factory. The company is conducting a feasibility study to assess whether the food wrap could compete, commercially, with conventional products, says Chen.

Scalability is sometimes an issue with bioplastics, which are typically more expensive to produce than their petrochemical counterparts. The soy-based wrap costs “almost nothing” to make in the lab, says Chen, because the raw materials are free of charge.

Commercial scale production would involve additional expenses, such as storage and quality control, however “we have not calculated those costs yet,” says Chen.

Chen’s soybean-based plastic wrap is digested by microbes and disappears completely within a month when disposed of in general household waste, without the need for heat.

Chen says he hopes neighboring soy-loving countries will be inspired by Singapore and adopt his innovation. He adds, “My dream is that our technology, which is cheap and simple to implement, will cut plastic and food waste and create a cleaner environment.”

Source

Bioplastics MAGAZINE, 2020-01-09.

Supplier

Nanyang Technological University (Singapore)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals