Modern aircraft are made from synthetic, non-renewable materials. Many of these are composites such as carbon and glass-fibre-reinforced plastics that are man-made through energy-intense processes.

To improve the sustainability of the aviation industry, researchers are investigating renewable and recycled materials to replace such composites. However, bio-based and recycled alternatives must meet the strict requirements required for safe and efficient flight.

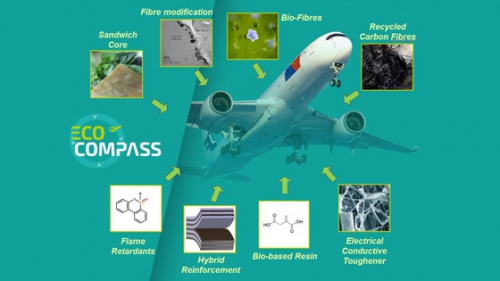

The EU-funded ECO-COMPASS project has identified potential bio-sourced and recycled materials that can be developed into eco-friendly composites for aircraft. Fibre reinforcements are used throughout aircraft and can contribute more than half of their structural mass.

The project team set out to look for alternative materials to create fibre reinforcements in planes and found that bio-based fibres from plants and recycled carbon fibres have great potential. The team has also developed a bio-based resin system that has promising properties for a range of in-aircraft applications.

“The bio-materials, recycled carbon fibres and bio-resins should be suitable for use in the secondary structure and interior of aircraft,” says project coordinator Jens Bachmann of the German Aerospace Center (DLR, Deutsches Zentrum für Luft- und Raumfahrt). “They typically require less energy to produce than the materials used at present.”

Collaboration with China

Key to the success of this project is the collaboration with researchers in China and industrial partners such as Airbus and Comac. By working together on a global scale, experts are combining their knowledge and expertise so that sustainable composites will be available to the aviation industry globally.

“The aviation industry continues to grow worldwide – global partnerships help us share knowledge and make rapid improvements to technologies,” notes Bachmann. “This collaboration has helped us learn more about fibres grown in China, such as ramie, that could be a good alternative to flax which is a standard fibre grown and used in Europe.

“Now, we are improving their properties by combining Chinese expertise in materials development with European expertise in modelling and simulation.”

Identifying the materials to develop

In future, the composite materials identified and developed during this project could become a part of planes in the form of interior panelling, gear doors, winglets and other secondary structures. Initial results have shown that bio-based composites made from flax and ramie plant fibres have the potential to be used in natural-fibre-reinforced plastics for aviation.

However, their properties must be altered to make them competitive with the glass-fibre-reinforced plastics currently in use. In particular, their tensile strength and fire-retardant properties need to be enhanced.

The team has also used recycled carbon fibres in combination with natural fibres to create promising composites. However, the properties of these hybrid systems must also be improved before they can be applied to aircraft.

In addition, the Sino-European team is developing a new bio-based epoxy resin made from rosin derivatives obtained from conifer plants. It is likely that this technique of embedding natural fibres into the resin will enable one component of the fibre-reinforced composite to be replaced with bio-based constituents.

“The project shows us which bio-based materials have a potential for use in aviation,” says Bachmann. “Natural fibres can be produced and treated at a lower environmental cost than their glass or carbon alternatives. The next step is to develop these so that they can become viable alternatives for use in planes.”

The project has already yielded a number of scientific papers and a special issue of a Chinese journal. In the coming year, a conference will be held for all stakeholders and another special issue is scheduled for publication in an aeronautical journal.

The partnerships and collaborative links that have been developed are allowing for cross-continental exchange of ideas and personnel. Furthermore, a number of PhD students currently being trained are creating and cementing relationships that will be pivotal for a sustainable aviation future.

Source

Bioplastics MAGAZINE, 2018-07-03.

Supplier

Deutsches Zentrum für Luft- und Raumfahrt e. V. (DLR)

European Union

Horizon 2020

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals