What is at stake?

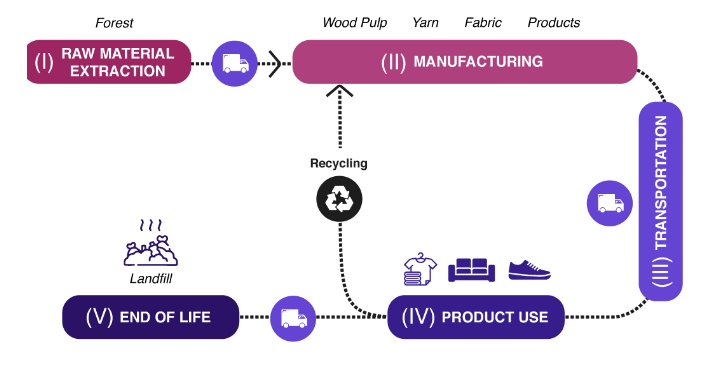

The production and use of wood-based textile fibres has been identified as a promising area for carbon storage and greenhouse gas emission reductions. However, other environmental impacts are potentially associated with the processing, manufacturing, use and disposal of (wood) products, including eutrophication, acidification, human toxicity and formation of air pollutants such as ozone. Currently the understanding of these impacts is limited, as there are no systematic studies available that have examined the non-climate environmental impacts occurring

throughout the life cycle stages.

Environmental impacts – what do we know?

The environmental performance of wood-based textile fibres is dependent on the benchmark used in assessments and the value chain’s complexity. As with any product or material, wood-based textile fibres have some impact to the environment. However, this does not necessarily mean that these fibres cannot be considered suitable alternatives to synthetic fibres or cotton from an environmental standpoint.

The wider adoption of wood-based textile fibres is limited by:

- Pending approval of alternative solvents (used to dissolve wood pulp) to reduce the environmental impacts.

- Lack of cost competitiveness for greener solvents (e.g., ionic liquids) in part due to limited production and consumption.

- • Difficulty for large manufacturing companies to adopt changes to systematically decrease environmental impacts due to the scale and complexity of their value chains.

- • Difficulty to increase fashion industry acceptance to use new wood-based fibres as they have different properties than traditional fibres, especially if producers do not work closely with designers and clothing brands.

- • Need for business model change, as current consumerism driven by “fast fashion” stimulates the notion of garment disposability, resulting in increasing volumes of waste.

- • Constrained consumer acceptance of limited options and increased price for more sustainable alternatives, despite awareness of environmental issues.

- Given the global distribution of the wood-based textile fibres value chain, more analyses capturing the entire value chain are required in the future.

Key messages:

(1) Invest in the management of chemicals used in textile fibre production by avoiding or considerably reducing the use of harmful chemicals, revamping the production process, and adopting circularity to minimize the generation of toxic wastewater.

(2) Integrate man-made cellulosic fibre mills with pulp mills to improve energy self-sufficiency, given modern pulp mills produce an excess of energy from side streams and waste. The resulting decreased use of fossil fuels can considerably lower environmental impacts.

(3) Only blend natural textile fibres, such as cotton with wood-based fibres, to help improve fibre recyclability and reduce waste. Blending natural with synthetic fibres makes recyclability difficult and costly, so textile companies should carefully consider which fibres to mix.

(4) New wood-based textile fibres are not meant to be direct substitutes for existing fibres. Future studies should take into consideration the differences in properties of wood-based textile fibres and their non-wood counterparts, as well as the uncertainty in their market uptake when performing calculations on substitution factors and market projections.

Please note: Wood-based textile fibres may substitute textile fibres made from other materials (e.g., petroleum-based fibres, cotton) by increasing in market share, and thereby avoiding or reducing greenhouse gas emissions associated with the production, use and disposal of these products.

See Verkerk et al. 2022 (https://doi.org/10.4060/cb7274en) for more information on such climate- related substitution effects.

Hassegawa, M.1, Orfanidou, T.1 2023. Environmental impacts of wood-based textile fibres. Policy Brief 5. European Forest Institute. https://doi.org/10.36333/pb5

1European Forest Institute

ISBN 978-952-7426-62-3 (print)

ISBN 978-952-7426-61-6 (pdf)

ISSN 2814-8142 (print)

ISSN 2814-8150 (pdf)

Disclaimer: The views expressed in this publication are those of the authors and do not necessarily represent those of the European Forest Institute, or of the funders.

Source

EFI publication, press release, 2023-04-18.

Supplier

European Forest Institute (EFI)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals