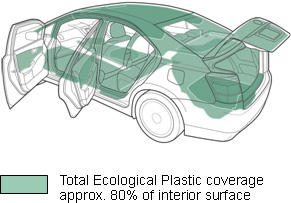

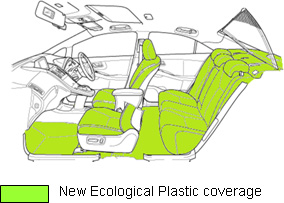

Toyota Motor Corporation (TMC) has successfully used “Ecological Plastic”1 to cover approximately 80% of the total interior surface area in the partially redesigned Japan-market “Sai” gasoline-electric hybrid sedan.

TMC achieved 80% coverage through the use of a new bio-PET-based2 Ecological Plastic in the seat trim, floor carpets, and other interior surfaces that require a higher abrasion-resistance than could be achieved with an earlier Ecological Plastic used in other parts of the interior. TMC’s new Ecological Plastic dramatically outperforms other general bioplastics in terms of heat-resistance, durability, and shrink-resistance, and performs on par with petroleum-derived plastics, with cost of parts included.

TMC considers Ecological Plastic to be instrumental to cutting CO2 emissions and to using less petroleum resources over the lifecycle of a vehicle, from manufacturing through to disposal. This is because the plastic uses plants, which absorb CO2 from the atmosphere as they grow, as a raw material instead of petroleum-derived plastics. Furthermore, the benefits of an environmental technology like Ecological Plastic are increased when used in mass-produced products such as automobiles.

TMC has been working on applying Ecological Plastic to automobiles since 2000. In May 2003, TMC became the first in the world to use bioplastic made from polylactic acid in a mass-produced vehicle when it introduced the material in the spare-tire cover and floor mats of the Japan-market “Raum” compact car. TMC achieved another world-first when it used its bio-PET Ecological Plastic in the trunk lining of the Lexus CT 200h released in January 2011.

TMC continues its proactive push in the development of new technologies and practical applications to further expand the use of Ecological Plastic in vehicle parts.

Use of Ecological Plastic in Interior Parts of Partially Redesigned ‘Sai’

Source

Toyota Motor Corporation, press release, 2011-10-11.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals