Empa and Lidl Switzerland have jointly developed a cellulose protective coating for fruit and vegetables. The novel coating is made from so-called pomace – squeezed fruit and vegetable peels. The innovative project can reduce packaging and prevent food waste.

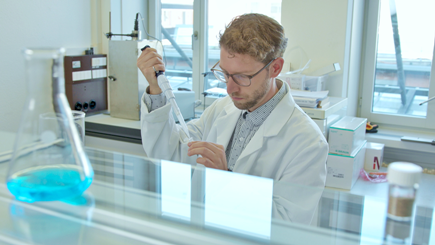

Plastic packaging in grocery stores protects fruits and vegetables from spoilage, but also creates significant amounts of waste. Together with the retailer Lidl Switzerland, Empa researchers have now developed a protective cover for fruit and vegetables based on renewable raw materials. For this project, Lidl chose Empa as a partner because Empa had decades of research experience with cellulose products.

Keeping fruits fresh at home

In Empa’s Cellulose & Wood Materials laboratory, the researchers then spent more than a year developing a special protective cellulose coating that can be applied to fruits and vegetables. The result: Coated fruits and vegetables stay fresh significantly longer. In tests, the shelf life of, for instance, bananas was extended by more than a week. This significantly reduces food waste. “The big goal is that such bio-coatings will be able to replace a lot of petroleum-based packaging in the future,” says Gustav Nyström, head of the Empa lab.

Production from press residues

The idea is to process so-called pomace into fibrillated cellulose. Pomace is the solid residue left over after extracting the juice from fruit, vegetables or plants. Previously, this plant leftover was disposed of in biogas plants or directly on the field; in the future, it will be used to create a protective coating for fresh fruit. The coating is either sprayed onto the fruit or applied to the produce as a dip and is easy to wash off. As it is harmless to the consumer, it can also be consumed without harm. The potential of cellulose coatings is by no means exploited yet; there is the possibility of adding additives such as vitamins or antioxidants.

Throughout the country

In summer, the highly promising preliminary study, which has been ongoing since 2019, was successfully completed and the main study launched. The cellulose layer developed at Empa will be tested and further improved over the next two years together with Lidl Switzerland and a fruit and vegetable supplier. The project is supported by Innosuisse, the Swiss innovation agency. The aim is for the new technology to be used in all 150 Lidl stores throughout Switzerland following the successful main trial.

To wrap or not to wrap: How ecological are plastic wrappers for cucumbers?

Plastic packaging waste is an immense problem for the environment. Retailers are therefore looking for ways to do without plastic packaging for food. However, not all fresh vegetables and fruits are provided by nature with a suitable protective cover that suits our cooling and storage conditions. Oranges and lemons may be so comfortable in the home refrigerator without a plastic cover that they last for weeks. Not so the tender cucumber! The dry air in the refrigerator does not agree with it, it becomes rubbery and possibly ends up in the trash. If, on the other hand, it is wrapped in a plastic cover, it stays crisp for longer.

Researchers at Empa in St. Gallen have now used life cycle assessment analyses to calculate how food waste due to spoiled food can be offset against the environmental impact of plastic packaging on imported cucumbers. For the model calculation, they followed the path of a cucumber from the producer in Spain to a Swiss supermarket. According to this, the plastic wrapping accounts for only 1% of the environmental impact caused by production and transport. Overall, the positive effect on the environment from less “food waste” is almost 5 times higher than the negative effect from packaging, according to the researchers.

C Shrivastava, E Crenna, S Schudel, K Shoji, D Onwude, R Hischier, T Defraeye; To wrap or not to wrap cucumbers? Preprint (2021)

Author

Rainer Klose

Source

Empa, press release, 2022-01-04.

Supplier

Eidgenössische Materialprüfungs- und Forschungsanstalt (EMPA)

Innosuisse

Lidl Switzerland

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals