Roswell Textiles announces that its proprietary biopolymer nonwoven materials, sold under the brand name of ECOFUSE™, are expected to reduce total GHG emissions by 3,750 MT CO2 per year, growing to over 10,000 MT CO2 by year 2030 as increased adoption is achieved. ECOFUSE™ technology is expected to initially reduce 1,500 MT CO2 in the Energy Sector with proprietary water filtration bags that are used in industrial water processing, 1,500 MT CO2 in the food and beverage industry by replacing synthetic polypropylene-based materials, 400 MT CO2 in the HVAC filtration industry and 350 MT CO2 in the Healthcare industry.

3,750 MT CO2 is a significant amount of carbon emissions. Here are some examples to help visualize how much CO2 that is:

- The average commercial flight produces around 0.11 MT CO2 per hour per passenger. 3,750 MT CO2 is equivalent to the emissions from approximately 34,000 passenger hours of air travel (that’s about 3.88 years of continuous flying).

- The average passenger car emits around 4.6 metric tons of CO2 per year. 3,750 metric tons of CO2 is equivalent to the annual emissions of approximately 815 passenger cars.

- It’s about the emissions of 194,000 propane cylinders used for home barbeques.

- It’s about 38.1 acres of forest preserved from deforestation.

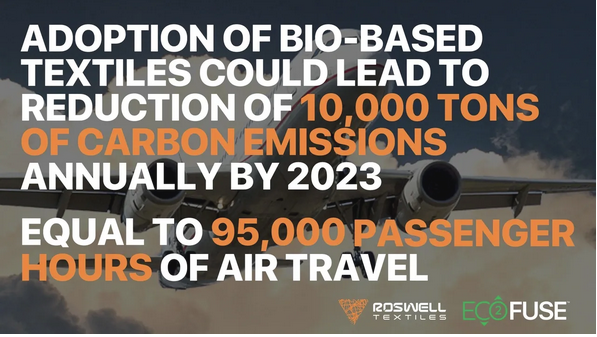

With increased adoption as ECOFUSE™ materials become more widely utilized in technical and product applications, the average GHG emission reduction achieved on an annual basis could exceed 10,000 MT CO2. 10,000 MT CO2 is approximately:

- 10,000 metric tons of CO2 is equivalent to the emissions from approximately 95,000 passenger hours of air travel (that’s about 10.84 years of continuous flying).

- 10,000 metric tons of CO2 is equivalent to annual emissions of approximately 2,170 passenger cars.

- It’s about the emissions of 517,000 propane cylinders used in home barbeques.

- It’s about 102 acres of forest preserved from deforestation

ECOFUSE™ materials are being used by Roswell Textile’s strategic partners and clients to decrease the carbon footprint of their products (generally speaking, the raw materials used to manufacture ECOFUSE™ have a 70% smaller carbon footprint than the conventional synthetic polymer materials made in the United States). The ECOFUSE™ materials are already commercial in medical filtration (510(k) approved face masks, respirators, etc.), water filtration (industrial water processing filters) and residential filtration applications (first HVAC filters made with plant-based materials) with additional commercialization processes underway for the use of ECOFUSE™ materials in hygiene, food and beverage packaging as well as in construction materials. ECOFUSE™ materials, once fully adopted and commercial, will be displacing conventional synthetic polypropylene plastics in medical gowns, drapes, wraps, bed sheets, pillows, dressings, wipes, coffee filtration, teabags, absorbent pads, insulation bags, packaging, home wrap, plastic wrap/packaging, HVAC filters, ventilators, fluid filtration, geotextiles, grain bags, silage wraps, seeding bags, and car filters.

Roswell Textiles, as a result of engineering and manufacturing their own production machinery in-house, utilizes proprietary production technologies that allow for the technical processing of biopolymers to achieve the high-performance requirements in nonwoven materials that have previously been impossible to achieve at commercial scale.

ECOFUSE™ materials are being used to increase OEM’s accomplishment of net zero carbon emissions in their product lines, as well as helping companies and industries reduce their carbon emissions to be in compliance with federally and internationally mandated carbon reduction policies. ECOFUSE™ meltblown materials, currently in commercial use in regulated and highly technical applications, are certified to be 100% biobased by the United States Department of Agriculture BioPreferred Program. ECOFUSE™ materials are eligible to create carbon offsets and directly align with The Paris Agreement, COP26 Initiatives, WHO, the Canadian Governments 2030 Emissions Reduction Plan, US federal executive orders and legislation (the Federal Buy Clean Initiative, Inflation Reduction Act, Building a Clean Energy Economy, and sustainable procurement initiatives).

About Roswell Textiles

Roswell Textiles is a global leader in biopolymer nonwoven technologies and materials, and the first and largest Canadian manufacturer of best-in-class synthetic and plant based meltblown nonwoven fabric for high performance, regulated medical, food grade, industrial filtration and consumer applications. Roswell Textiles mission is to de-carbonize the nonwoven industry by developing plant based and low carbon materials on a large scale. The ECOFUSE™ platform technology is the world’s first commercially available plant based meltblown nonwoven material that is rapidly helping transition the world towards a lower carbon and more circular material future. Roswell Textiles is a wholly owned subsidiary of PADM Group Inc.

About PADM Group

PADM Group is an operationally diverse, advanced manufacturing conglomerate focused on mid to high volume manufacturing in the healthcare/medical, nonwoven textiles, energy/industrial, and aerospace/defence industries. PADM Group has a brand focus on innovation and highly agile commercialization of sustainable technologies and products.

Source

Roswell, press release, 2023-05-16.

Supplier

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals