Decarbonizing the planet is a process revolving around some fields in which certain challenges connected to Sustainable Energy Transition still need solving. Innovation initiatives in development make possible to construct houses and roads with cement or pitch capable of trapping CO2, removing it from the atmosphere and thus reducing the carbon footprint. Moreover, innovative mattresses made from synthetic polyurethane foam are manufactured using recycled CO2. Also, we can eat foods supplied in a completely sustainable and self-sufficient way which were grown using CO2-based fertilizers.

The role of CO2 in the future sustainable transport

In the particular case of the transport sector, the sustainable future is already here. In fact, we can find inspiration in how plants and microorganisms turn CO2 into energy. This concept can help us obtain biofuels capable of satisfying our growing need for sustainable energy for future transport. In a few years (around the year 2030), the development of novel ongoing technologies will make it possible to travel in aircraft powered by fuel (kerosene) synthesized from CO2 as well as obtain synthetic fuels derived from CO2 for trucks. This way the dependency on fossil fuels will be substantially reduced to promote carbon-neutral mobility to help stop climate change.

E-fuels for carbon neutral mobility

To decarbonize the transport sector, focusing on synthetic and sustainable fuels to help CO2 mitigation to translate climate ambitions into actions.

“Sustainable” fuel requirements include the reduction of carbon emissions during its lifecycle. Nevertheless, we also cannot forget other factors such as the limitations of the need for fresh water and the prevention of deforestation in the chemical processes developed for this aim.

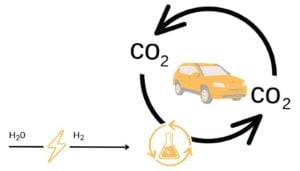

Synthetic fuels, biofuels, and e-fuels are liquid fuels, similar to common hydrocarbons such as gasoline or diesel, but in contrast they are not made from fossil sources. These sustainable liquids are obtained from the reaction of renewable hydrogen with industrial-captured CO2. This way, the captured CO2 is offset by the CO2 generated from the use of the e-fuel. CO2 use creates new opportunities for economic growth through innovation, leading us to a transition to a circular economy and decarbonization with less dependency on fossil fuels.

What is considered a green fuel?

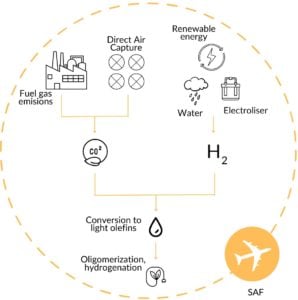

To be classified as a “green fuel” the employed energy for the obtention needs to be renewable, such as the electricity to separate hydrogen and oxygen through electrolysis. In the case of aviation, SAF (sustainable aviation fuels) are now a viable alternative. SAF are currently being used in commercial flights [1],[2] and it is demonstrated that their use reduces CO2 emissions by up to 80%.

The physical and chemical characteristics of SAF are almost identical to those of conventional aviation fuels. In fact, SAF can also be mixed with conventional fuels in different proportions. They use the already existing infrastructure and do not require new motors and hence are considered drop-in fuels as it can automatically incorporated into already existing fuel supplies.

E-fuels also need to meet three key requirements:

- Be continuous resources that avoid resource depletion as well as being economically, socially, and environmentally sustainable.

- Be produced using raw materials other than petrol, carbon, or natural gas.

- Have the technical requirements and certification for being used on commercial aircraft.

Technologies for producing drop-in biofuels

In general, the developed technologies used to produce drop-in biofuels can be divided into four main categories:

- Oleochemical

- Thermochemical

- Biochemical

- Hybrid processes

Challenges and opportunities of low-carbon fuels

Many companies are either producing or trying to commercialize bio-jet fuel in different phases of technological preparation[3],[4],[5]. It is important to highlight that emissions are a decisive factor for the evaluation of the technology, being the true indicator of the real value of biofuel and the cost of reducing carbon emissions. Thus, the challenges associated with the commercialization of a low-carbon fuel may differ depending on the technology used, since some processes require a large capital investment (gasification-Fischer Tropsch) and others require raw materials of high cost.

Besides obtaining biofuels from hydrotreated vegetable oils (HVO) or hydroprocessed esters and fatty acids (HEFA) that have become commercialized, the commercialization of other methods is still in progress. However, as a conclusion, although the technological challenges are important, sustainability and cost are the determining factors for the technology to be successful.

To summarize, the use of CO2 as a prime material or co-reactant is now both a challenge and an opportunity, as it stimulates the search for new solutions in the chemical industry for decarbonization and the decrease of our dependency on fossil fuels in the case of transport.

AIMPLAS can help your company with the challenges of decarbonating, obtaining more sustainable fuels, and designing catalysts that will help you overcome these challenges.

Source

Aimplas, press release, 2023-10-05.

Supplier

AIMPLAS (Asociación de Investigación de Materiales Plásticos y Conexas)

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals