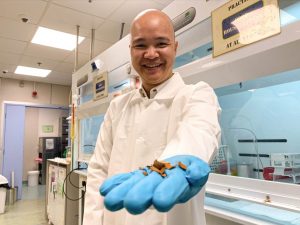

However, a team of international scientists led by Nanyang Technological University, Singapore (NTU Singapore) has found a way to deal with the problem. By processing the tamarind shells which are rich in carbon, the scientists converted the waste material into carbon nanosheets, which are a key component of supercapacitors – energy storage devices that are used in automobiles, buses, electric vehicles, trains, and elevators.

The study reflects NTU’s commitment to address humanity’s grand challenges on sustainability as part of its 2025 strategic plan, which seeks to accelerate the translation of research discoveries into innovations that mitigate our impact on the environment.

The team, made up of researchers from NTU Singapore, the Western Norway University of Applied Sciences in Norway, and Alagappa University in India, believes that these nanosheets, when scaled up, could be an eco-friendly alternative to their industrially produced counterparts, and cut down on waste at the same time.

The tamarind shell-derived nanosheets also showed good thermal stability and electric conductivity, making them promising options for energy storage.

The researchers hope to explore larger scale production of the carbon nanosheets with agricultural partners. They are also working on reducing the energy needed for the production process, making it more environmentally friendly, and are seeking to improve the electrochemical properties of the nanosheets.

Source

Nanyang Technological University, press release, 2021-07-14.

Supplier

Alagappa University

Nanyang Technological University (Singapore)

Western Norway University of Applied Sciences

Share

Renewable Carbon News – Daily Newsletter

Subscribe to our daily email newsletter – the world's leading newsletter on renewable materials and chemicals